Inkjet head driving method, inkjet head driving device, and inkjet printing device

A driving method and technology of a driving device, which can be applied in directions such as printing, can solve the problems of complicated ink supply system and difficult operation of heads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

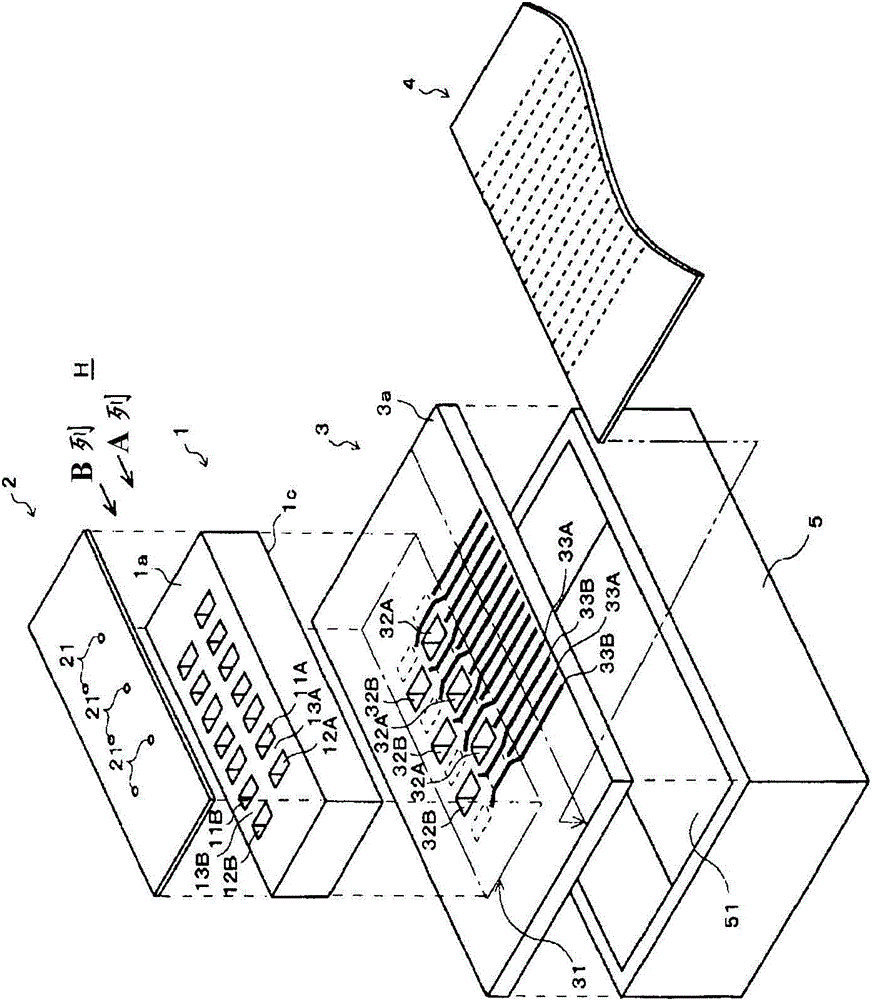

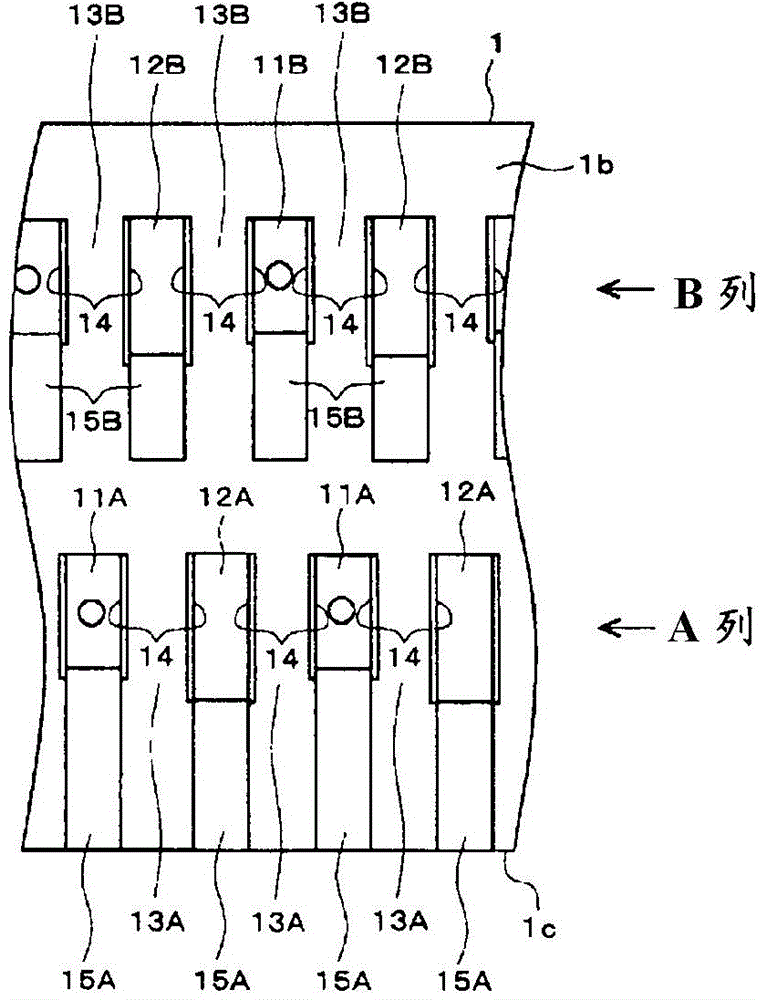

[0112] ready to have with figure 2 In an inkjet head having two channel rows having the same structure as the inkjet head shown, one channel row is used as drive group A, and the other channel row is used as drive group B. Each channel row has 256 nozzles, the distance D between the nozzles between the channel rows is 1.128 mm, and AL=5.0 μs.

[0113] The two channel columns of the inkjet head are driven by the same driving circuit.

[0114] The ink used for this inkjet head had a viscosity of 10 mPa·s, a surface tension of 32 mN / s, and a sound propagation speed in the ink of 1300 m / s.

[0115] According to the above conditions, the value of the pressure wave transmission time t obtained by "distance between nozzles between driving groups" / "speed of sound propagating in ink" is 1128 (μm) / 1300×10 6 (μm / s)=0.87×10 -6 (s) = 0.87 (μs), and here, t = 0.9 (μs) based on this calculated value.

[0116] The driving signal applied to each driving channel from the driving device use...

Embodiment 2

[0127] Crosstalk and driving load were evaluated in the same manner as in Example 1 except that the phase difference (nAL+t) was set to n=2, which was 2×5.0+0.9=10.9 μs. The results are shown in Table 1.

Embodiment 3

[0135] Prepare to list the nozzles of the inkjet head as Figure 11 In the inkjet head having four columns as shown, all channel columns are divided into two drive groups A and B so that the drive groups differ between adjacent channel columns. Each channel row has 256 nozzles, and the nozzle-to-nozzle distance D between the channel rows forming different drive groups is 0.846 mm, and AL=5.0 μs.

[0136] The four channels of the inkjet head are listed as Figure 15 The ground shown is driven by two drive circuits.

[0137] The ink used for this inkjet head had a viscosity of 5.7 mPa·s, a surface tension of 41 mN / s, and a sound propagation speed in the ink of 1600 m / s.

[0138] According to the above conditions, the value of the pressure wave propagation time t calculated by "the distance between the nozzles between the rows of adjacent pressure chambers" / "the speed at which sound propagates in the ink" is 846 (μm) / 1600×10 6 (μm / s)=0.53×10 -6 (s) = 0.53 (μs), and here, t ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com