Patents

Literature

75results about How to "Solve crosstalk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

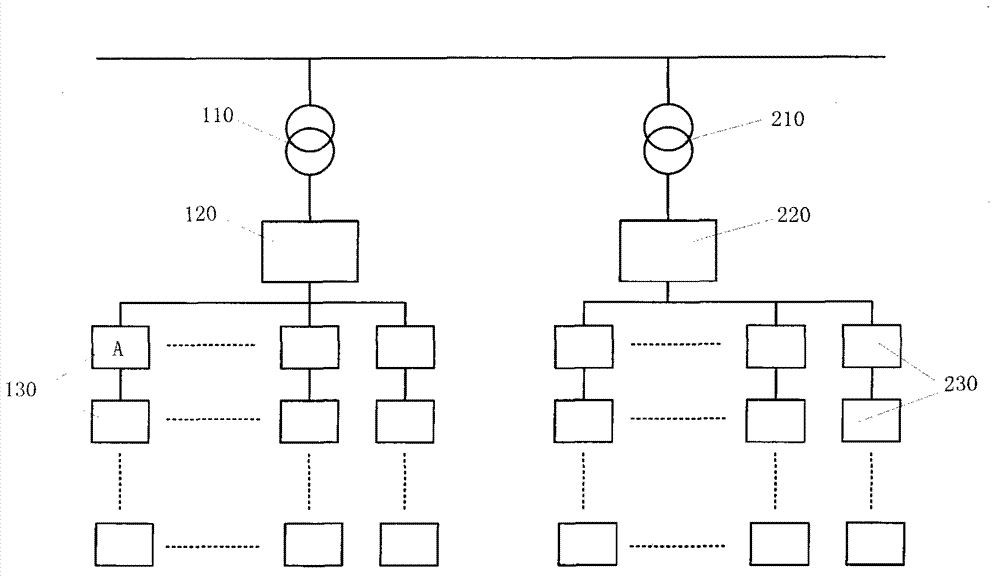

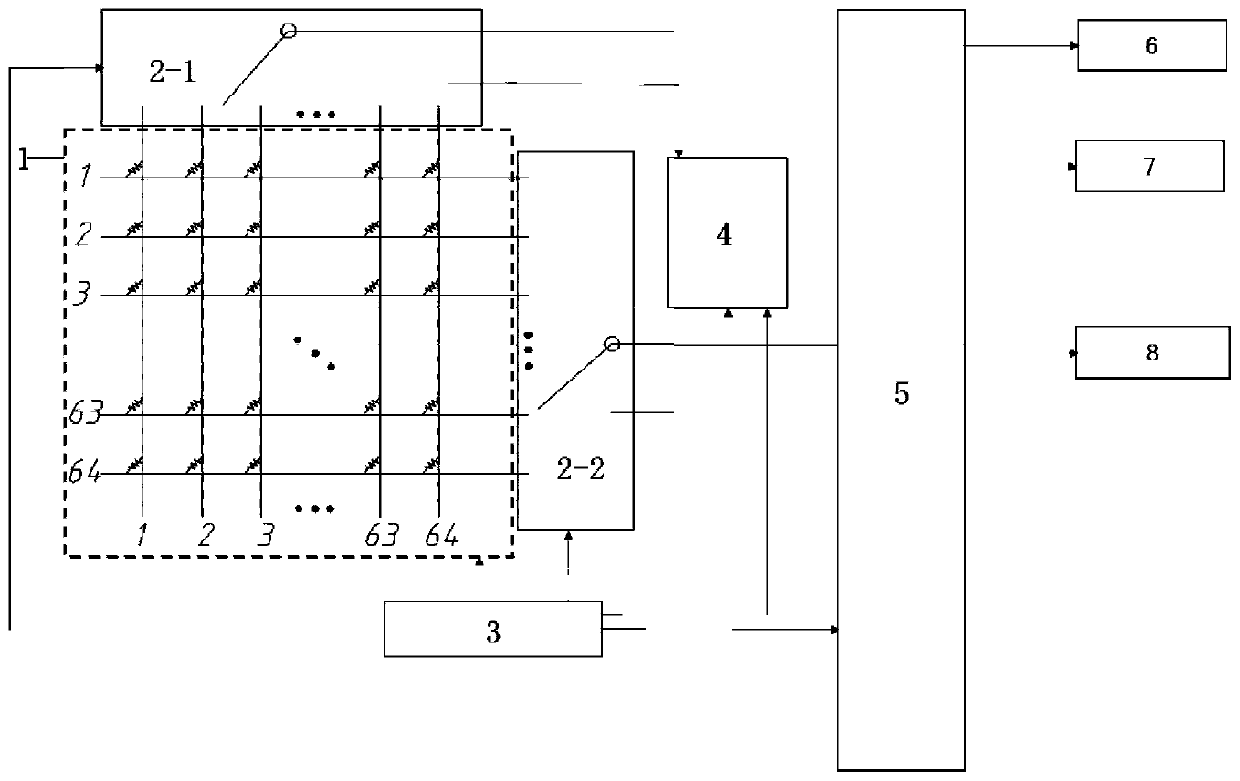

Method, apparatus and system of signal processing

ActiveCN102318302ASolve crosstalkCross-talk reductionSupervisory/monitoring/testing arrangementsSignal onVIT signals

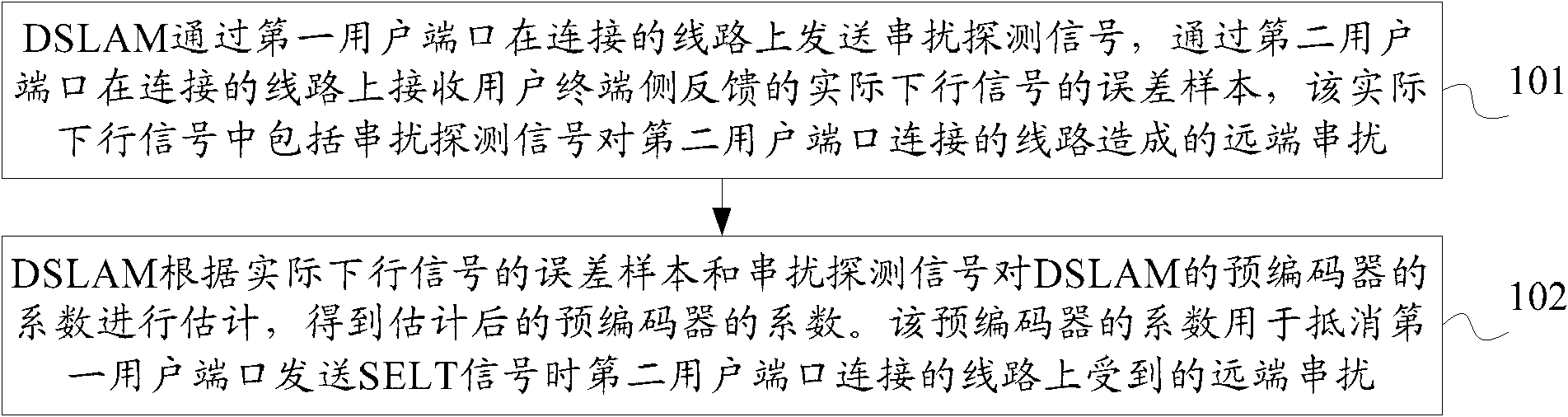

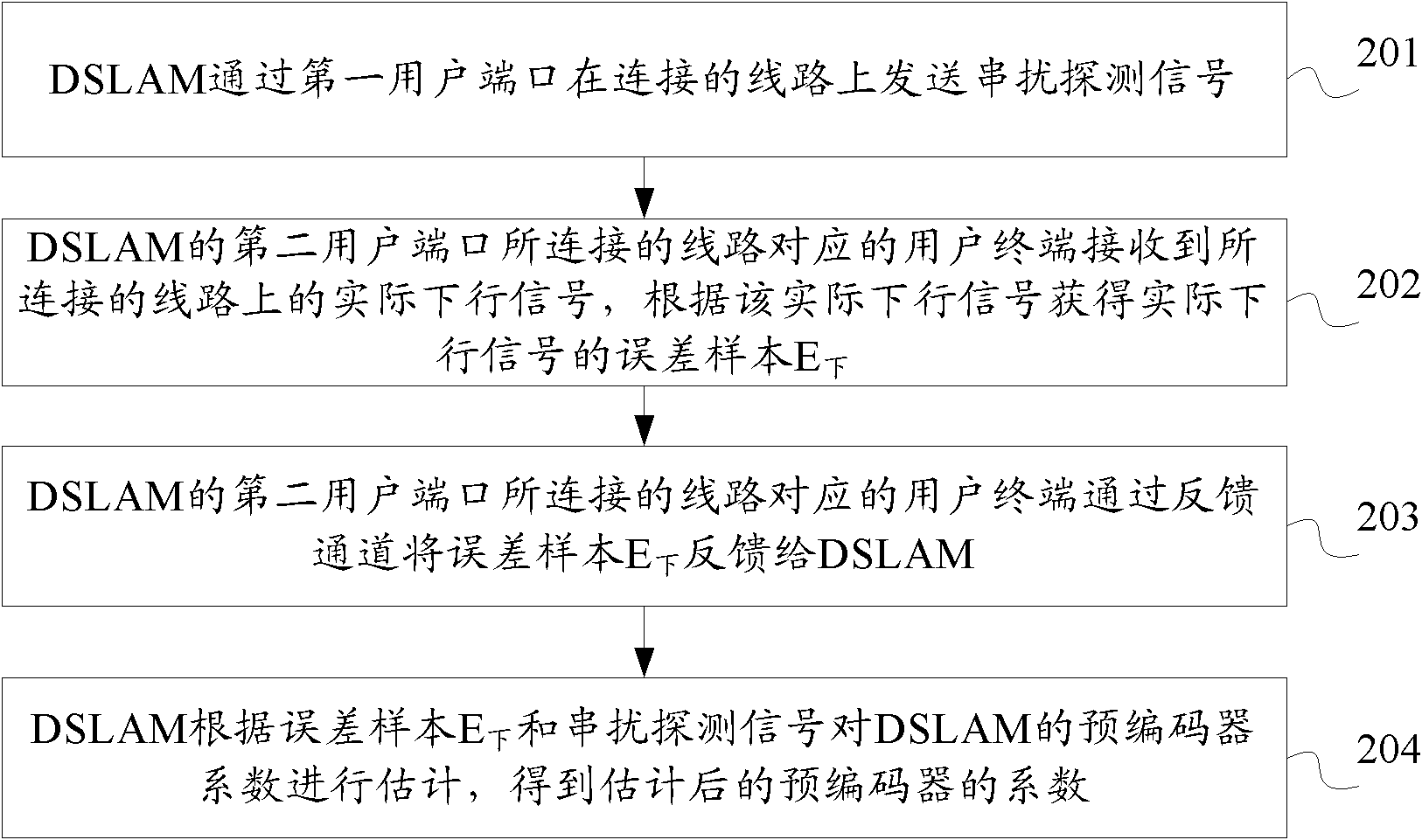

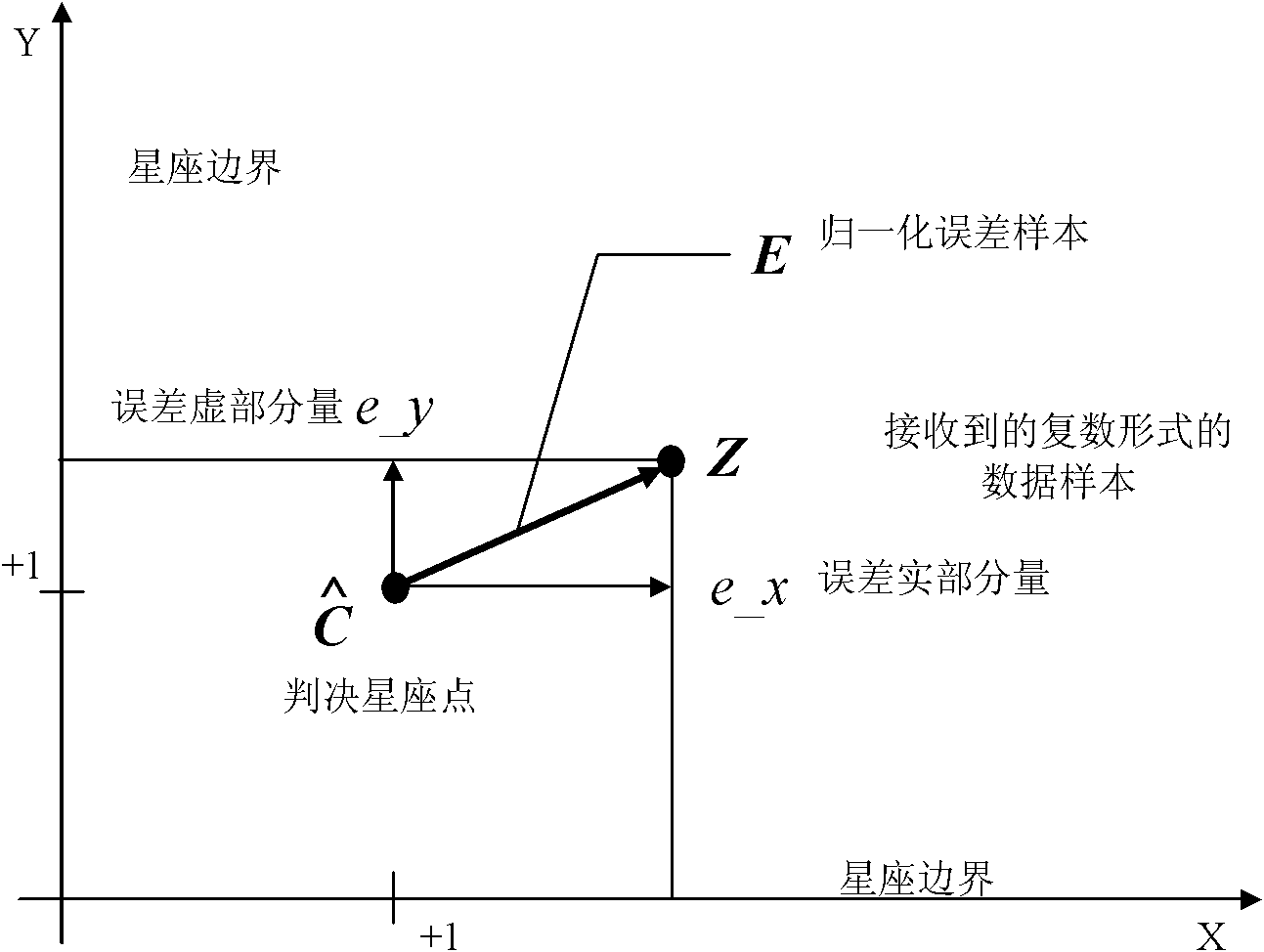

The invention provides a method, apparatus and system of signal processing. The method comprises: sending crosstalk detection signals on an interconnection line through a first user port; receiving an error sample of an actual downgoing signal feedback by a terminal side on an interconnection line through a second user port; evaluating the coefficient of DSLAM precoder on the basis of the error sample of the actual downgoing signal and the crosstalk detection signal, and obtaining the evaluated precoder coefficient which is used to offset the far-end crosstalk which the interconnection line of the second user port suffers when the first user port sends SELT signal.

Owner:HUAWEI TECH CO LTD

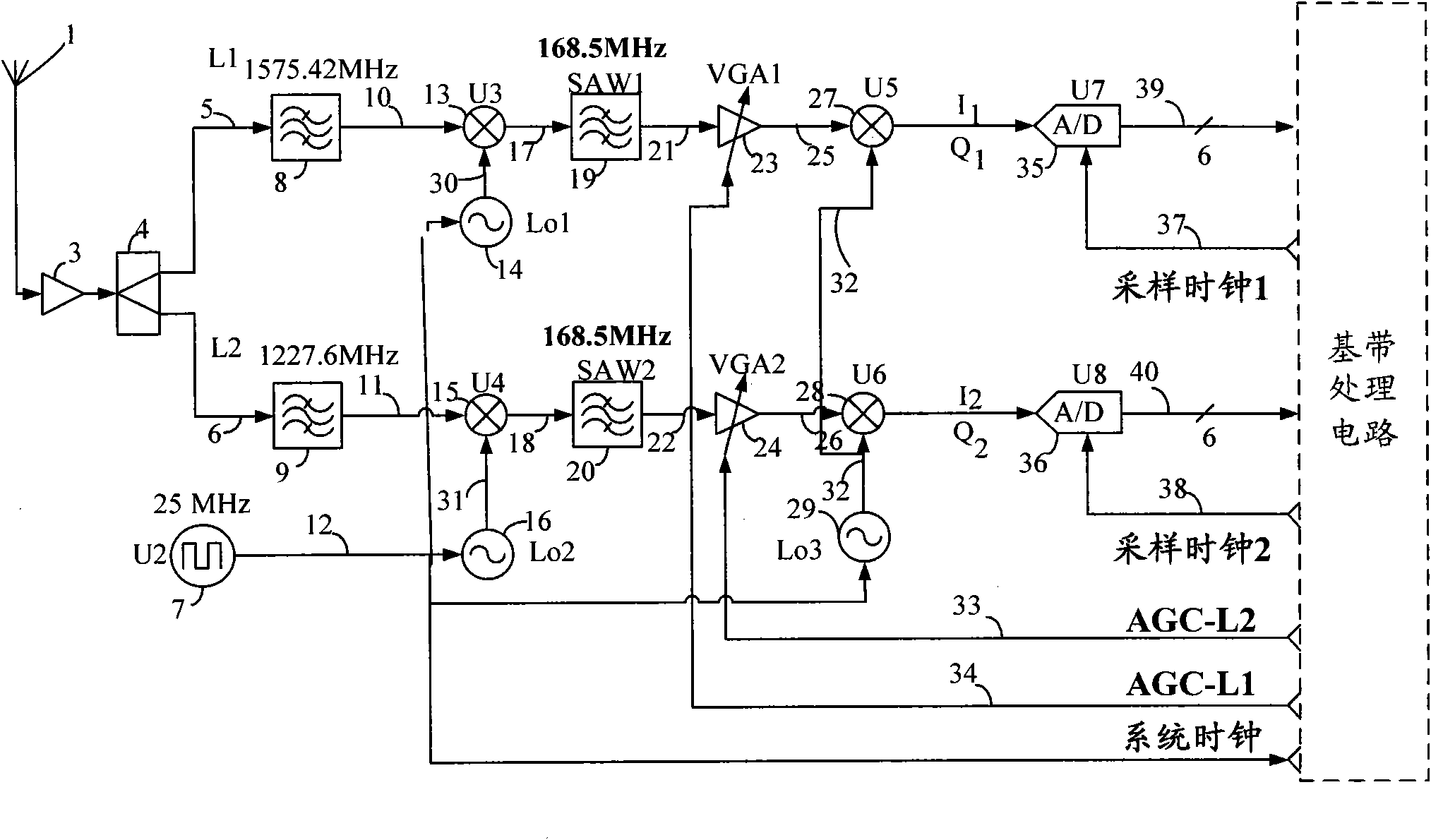

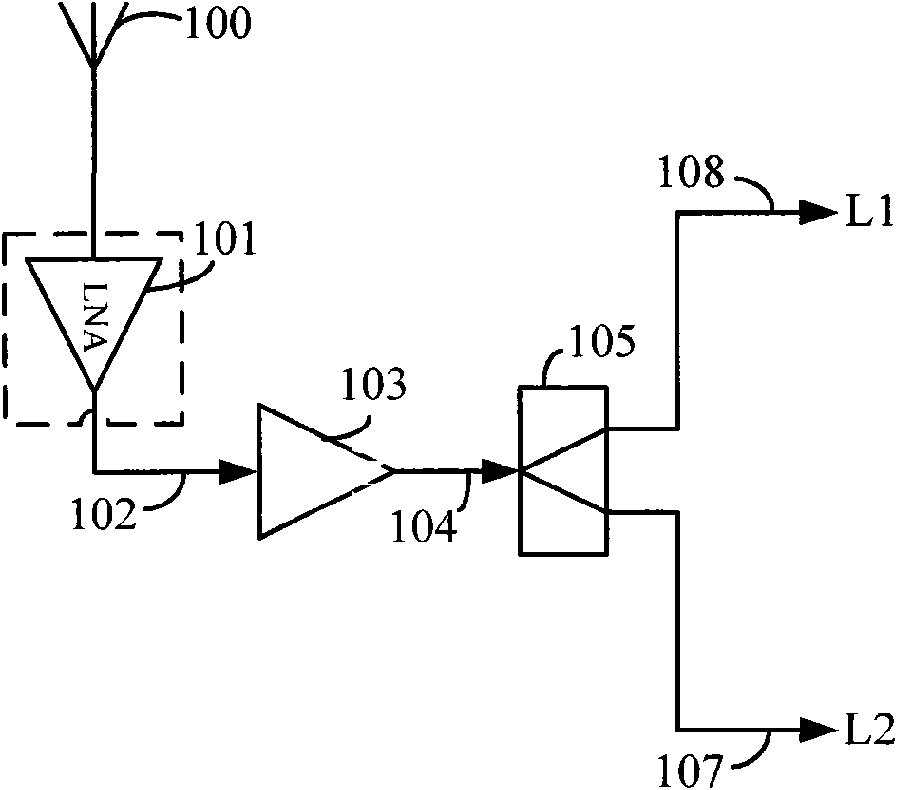

Radio frequency structure for realizing function of switching dual-band GPS satellite signal into base band signal

InactiveCN101629996ASimple structureEasy to useBeacon systems using radio wavesPosition fixationLocal oscillator signalIntermediate frequency

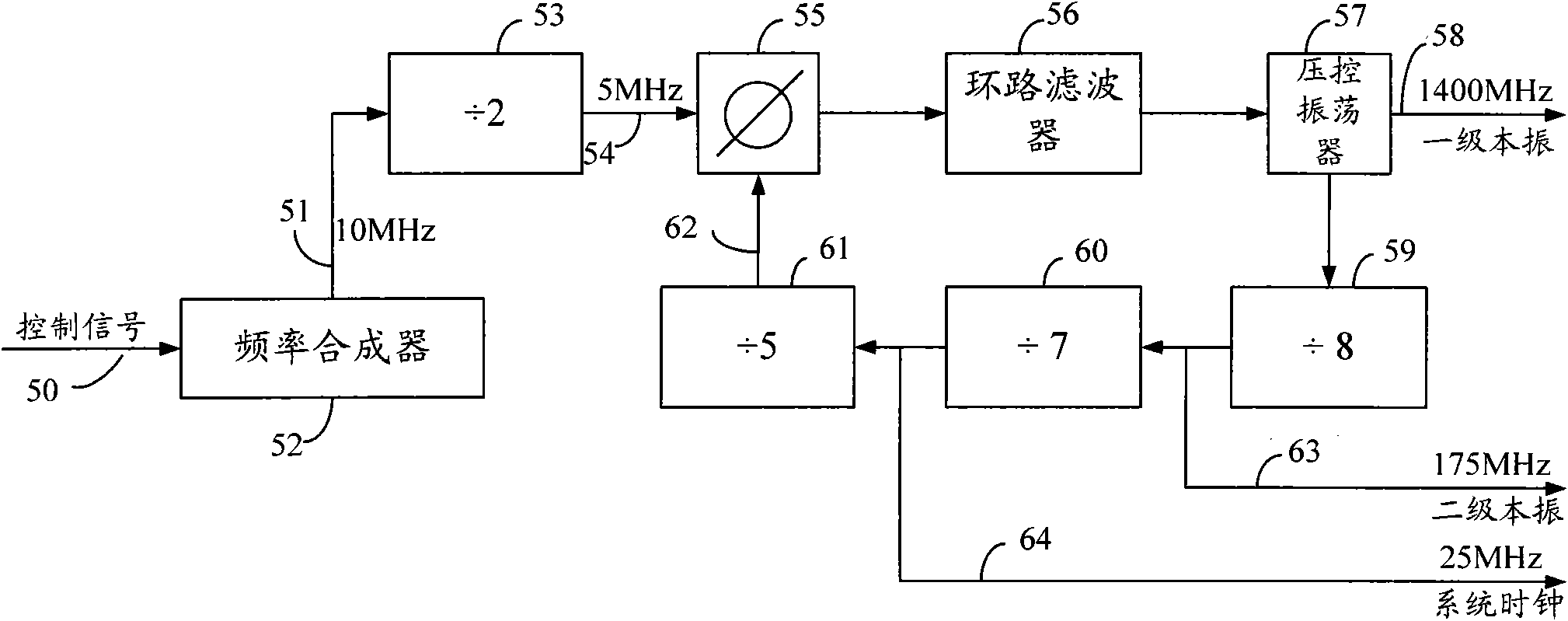

The invention relates to a radio frequency structure for realizing the function of switching dual-band GPS satellite signal into base band signal; wherein GPS satellite signal is divided into circuits of L1 frequency band and L2 frequency band, and generation circuits of local oscillator 1743MHz, 1059MHz, 336MHz and clock signal 25MHz, a processing circuit for converting down GPS satellite signal into intermediate frequency signal, and a circuit of I path and Q path digital signal obtained by processing the intermediate frequency signal by orthogonal demodulation, filtration and A / D conversion after being received. The difference between a primary local oscillator signal frequency of L1 and the L1 frequency band of GPS satellite signal is positive, the difference between a secondary local oscillator signal frequency of L2 and the L2 frequency band of GPS satellite signal is negative, and the primary local oscillator signal frequency of L1 and the primary local oscillator signal frequency of L2 are respectively generated by different frequency synthesizers. The adoption of the radio frequency structure not only solves the mutual interference problem of channel signals, but also enhances the signal-to-noise ratio of the system. The circuit structure is simple and practical, the working performance is stable and reliable, and the application range is wider.

Owner:SHANGHAI HUACE NAVIGATION TECH

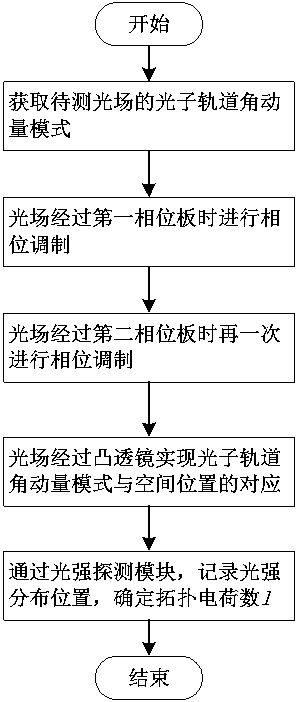

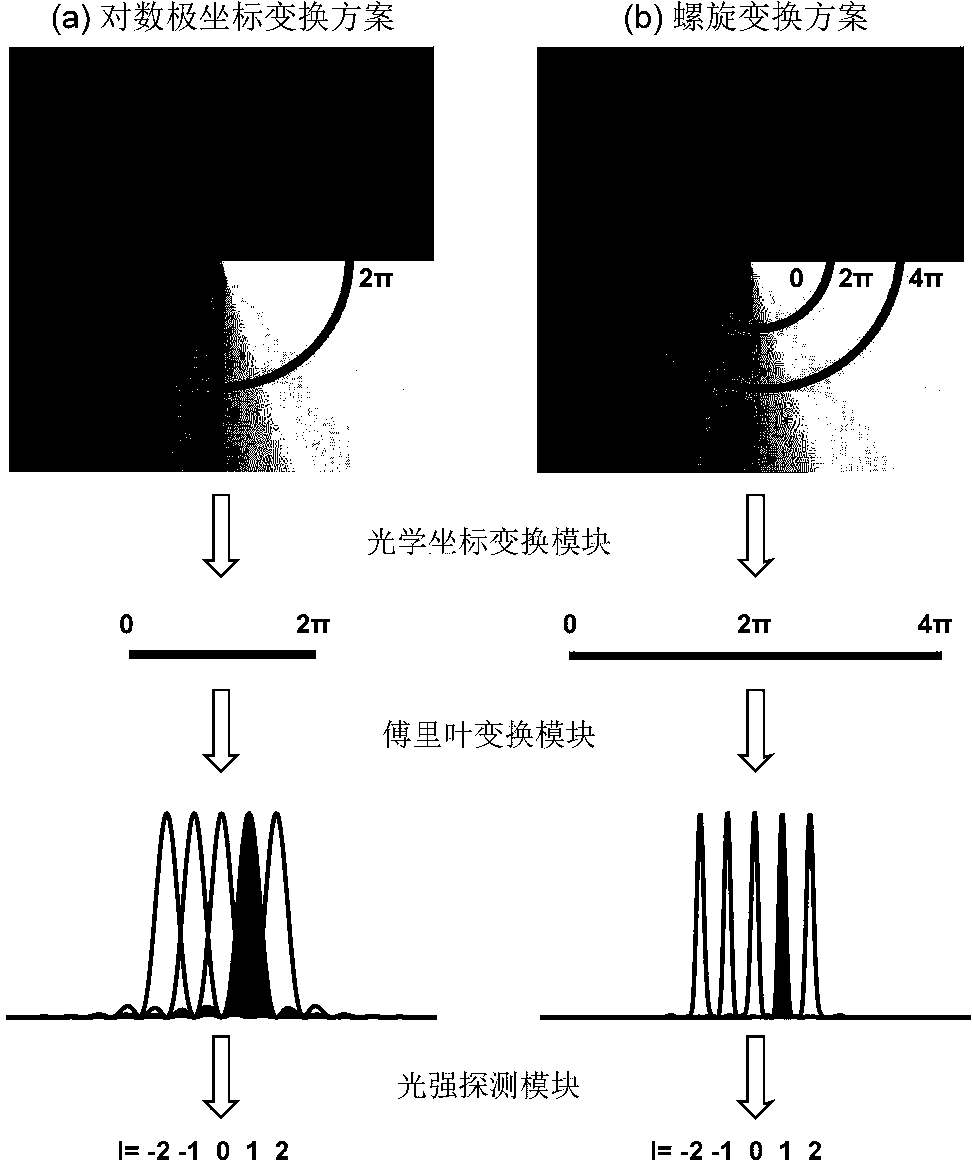

Photon orbital angular momentum mode measurement method and system based on helical transformation

ActiveCN108923880AOvercoming Adjacent Mode Crosstalk ProblemsHigh-resolutionOptical mode multiplex systemsPhotometry using electric radiation detectorsMomentumAngular momentum

The invention discloses a photon orbital angular momentum mode measurement method and system based on helical transformation. The method comprises the following steps: a phase plate at an input planemaps an incident light field to a straight line of an output plane along a helical path on the input plane, and the phase plate at the output plane compensates the phase accumulated by propagating thelight field to the output plane from the input plane in the above transformation process, thereby a the to-be-tested photo orbital angular momentum mode at the input plane into a plane wave mode withthe specific tilt wave-front at the output plane; and then a convex lens focus the plane wave modes with different tilt wave-fronts on different locations of the focal plane, thereby realizing one-to-one corresponding and detection of the to-be-tested photo orbital angular momentum mode and the space location. The adjacent model crosstalking problem caused by demodulation facula widening is effectively overcome, and the high-resolution photon orbital angular momentum mode measurement is further realized when the high demodulation efficiency is maintained.

Owner:SUN YAT SEN UNIV

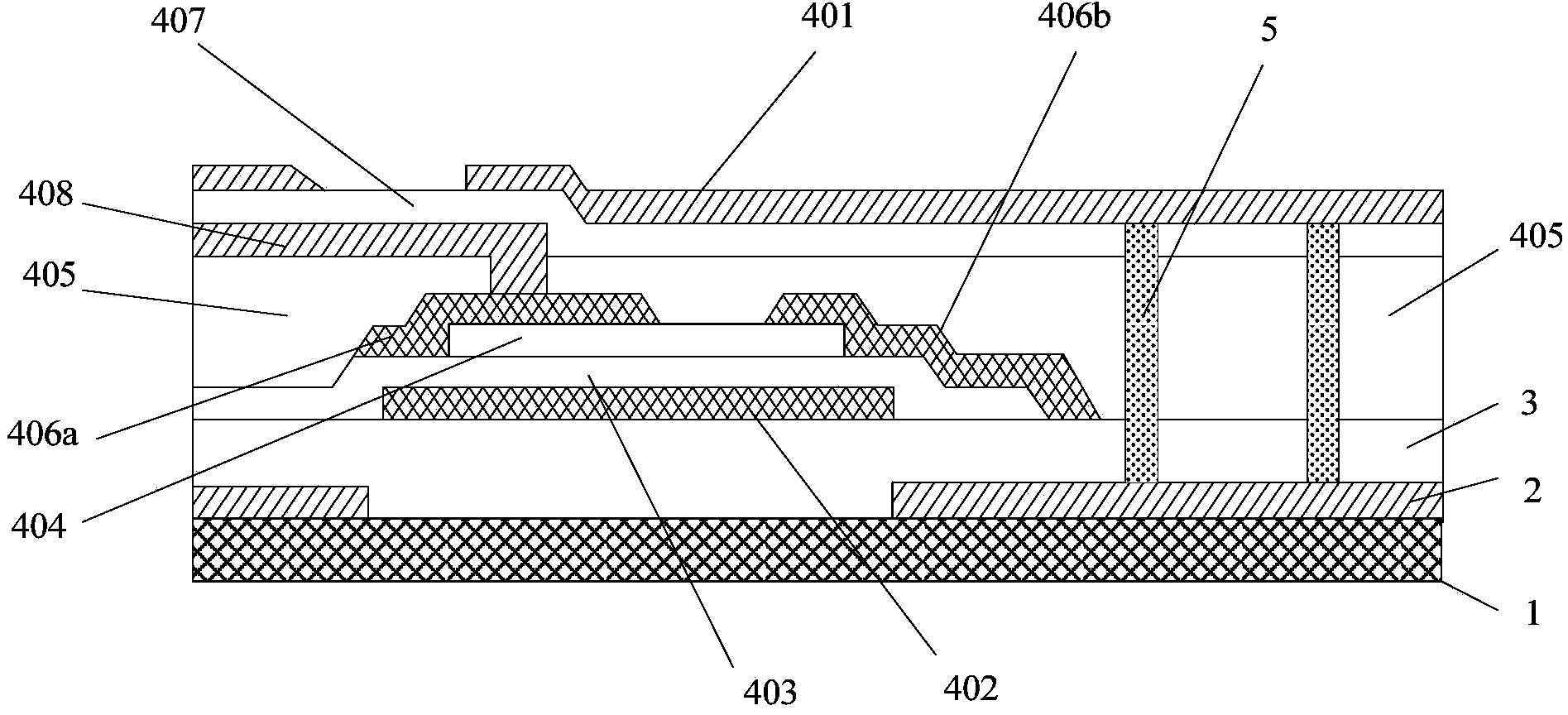

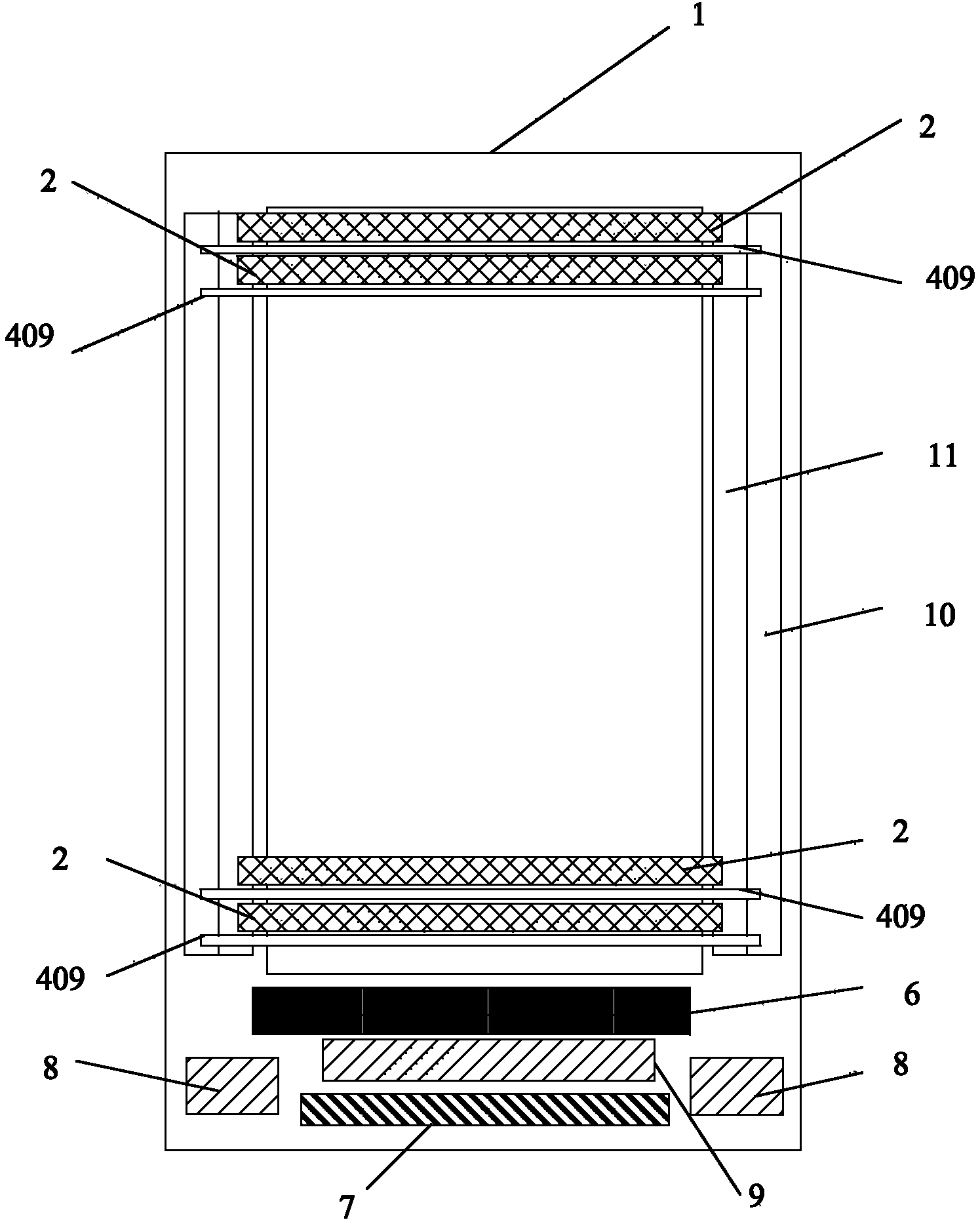

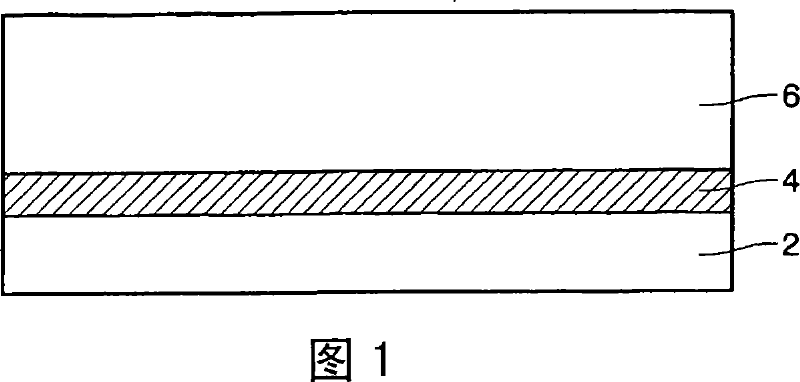

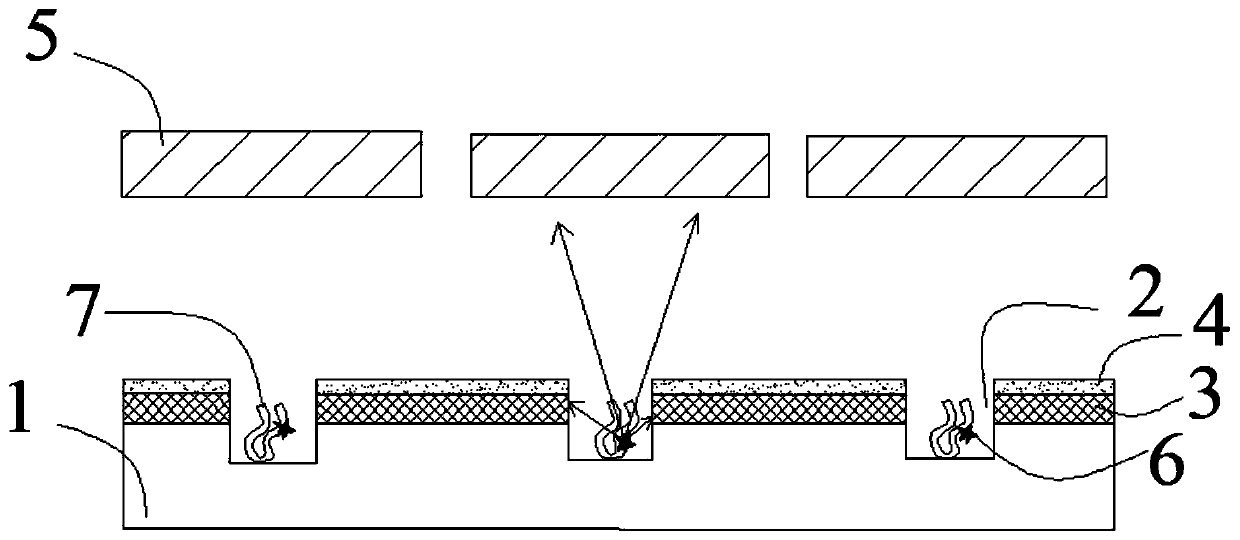

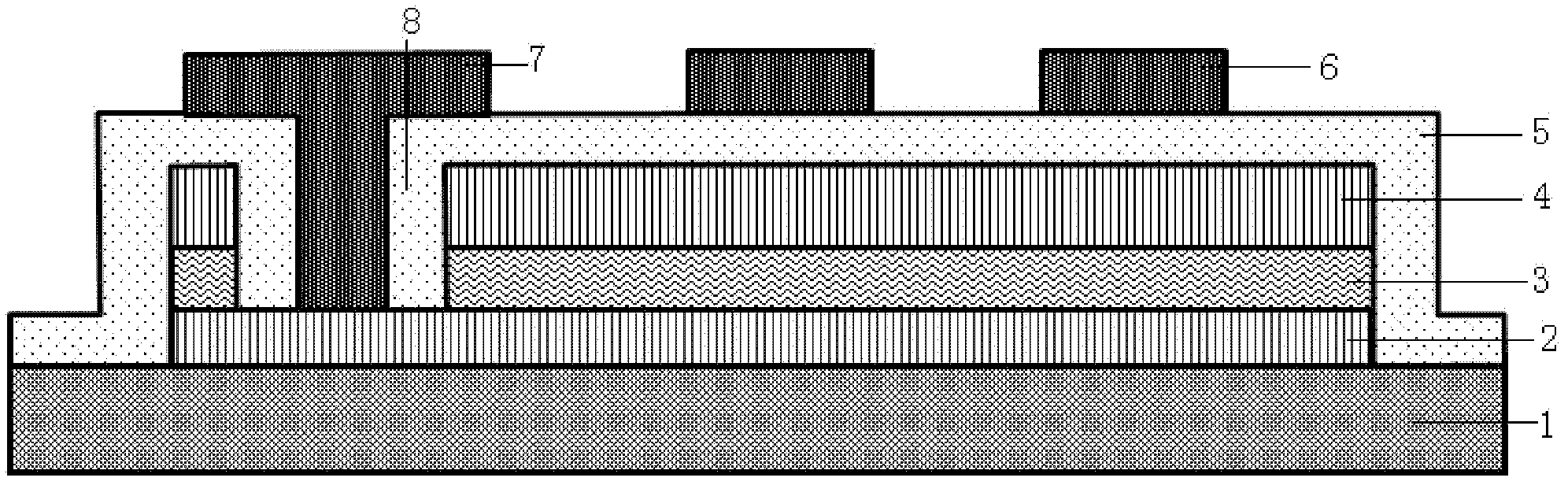

Array substrate, manufacturing method thereof and display device

ActiveCN103474436AReduce crosstalkImprove picture qualitySolid-state devicesSemiconductor/solid-state device manufacturingImaging qualityDisplay device

The invention provides an array substrate, a manufacturing method thereof and a display device. The array substrate comprises a liner and a public electrode layer located on the liner. The array substrate is characterized by further comprising a conductive layer located on the surface of the liner, and the conductive layer and the public electrode layer are connected in parallel. The array substrate solves the problems that an existing public electrode is large in resistance and causes a crosstalk of an array substrate and a greenish phenomenon. Different from a mode that a public electrode with a single-layer transparent conductive film is used in the array substrate in the prior art, according to the technical scheme, the array substrate is additionally provided with a conductive layer, so that an equivalent resistor of the public electrode and an equivalent resistor of the conductive layer are in parallel, the resistance value of the public electrode is reduced, the crosstalk and greenish phenomena of the array substrate are reduced, and image quality of the display device is improved.

Owner:BOE TECH GRP CO LTD

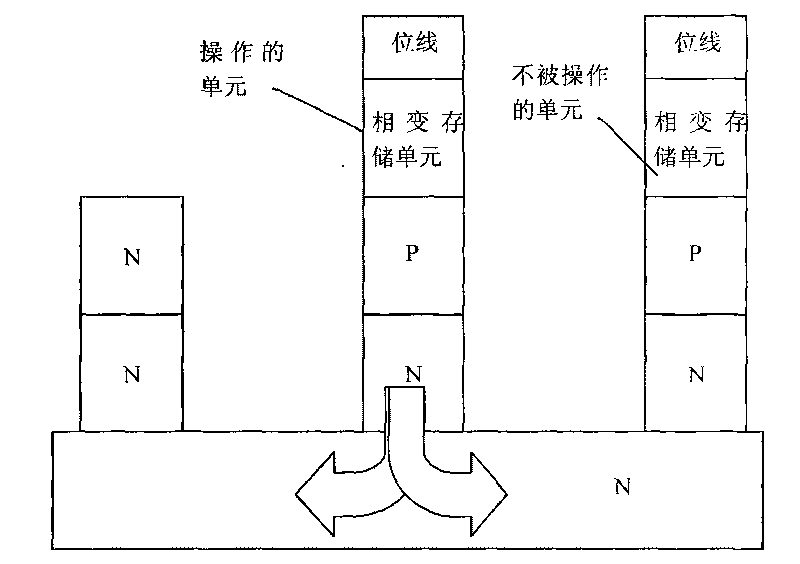

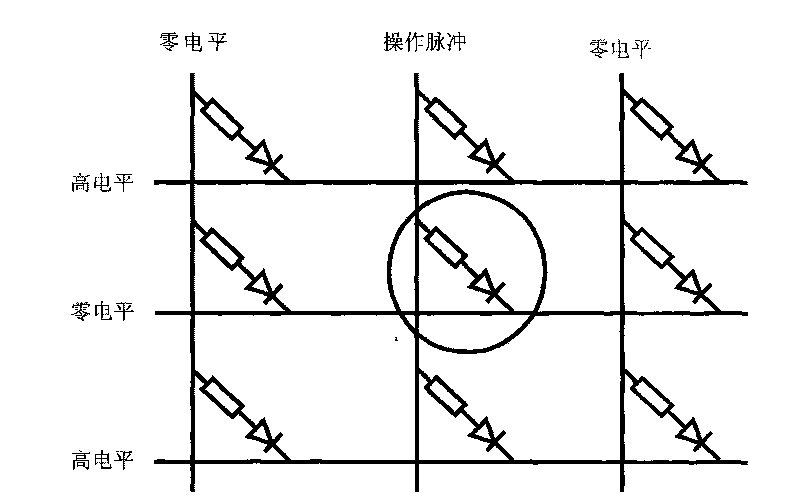

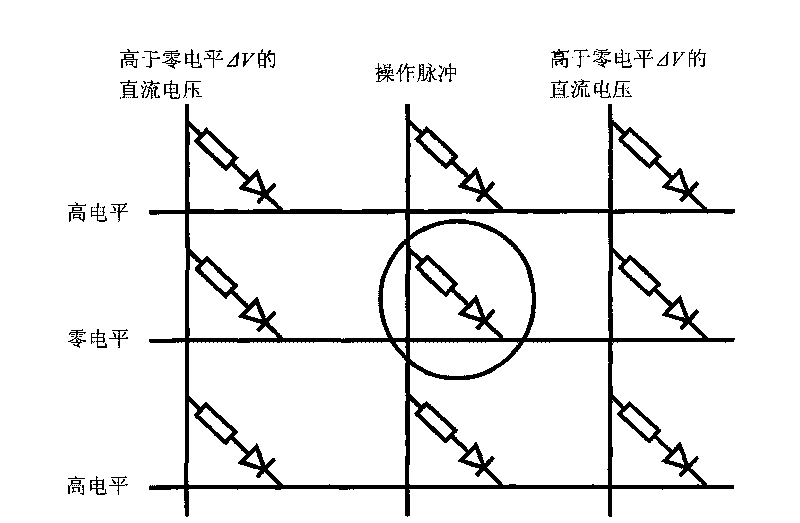

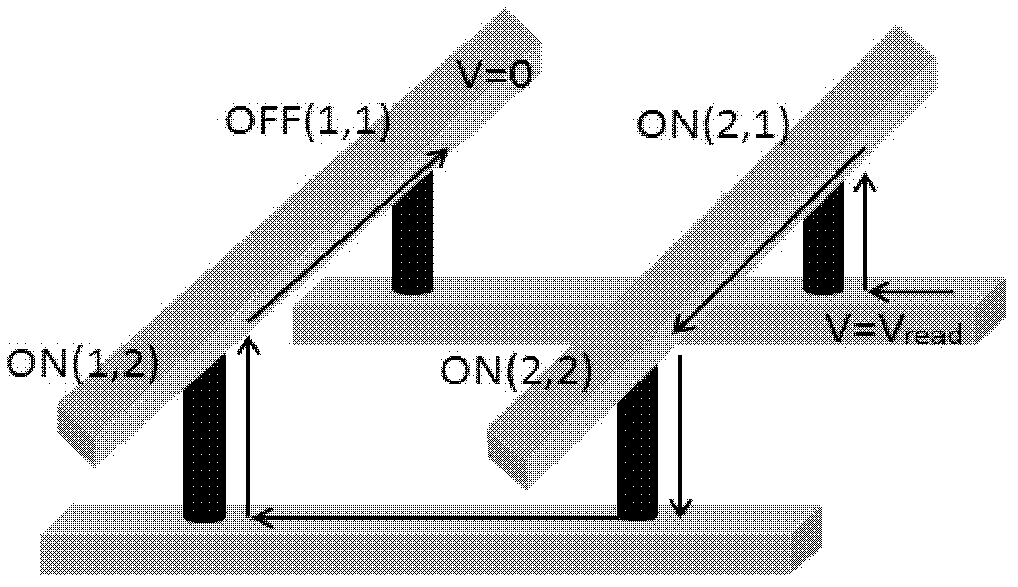

Gating method of memory and circuit structure implementing same

The invention discloses a gating method of a memory and a circuit structure implementing the method. The memory uses a diode as a gating device to apply operating pulse and pull-down of word line voltage to bit lines of memory cells to be operated when read-write operation is performed and apply a direct current voltage higher than the word line voltage to the bit lines of memory cells which are free from read-write operation and in the same word line with the memory cells to be operated, so that a leakage current which is generated due to parasitic triode effect is zero and crosstalk problem caused by the leakage current is radically solved on the circuit. The direct current voltage higher than the word line voltage is generated via a peripheral circuit.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

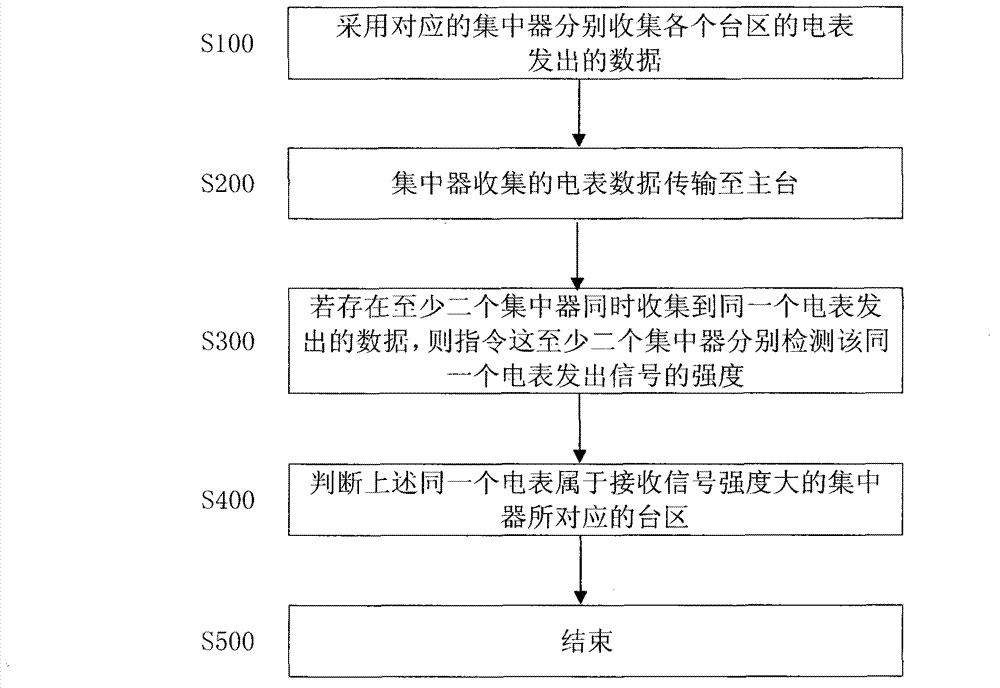

Method and device for determining region of ammeter by detecting signal intensity

InactiveCN103310623ASolve crosstalkAvoid crosstalkElectric signal transmission systemsTransmission noise suppressionData transmissionAutomatic meter reading

The invention discloses a method and a device for determining a region of an ammeter by detecting signal intensity. According to the method, when a master station discovers that two concentrators collects the data transmitted by the same ammeter, the two concentrators are enabled to detect the intensity of a received signal transmitted by the ammeter, the ammeter can be determined to belong to a party with high receiving signal intensity, so that the crosstalk problem in an automatic meter reading system can be solved. The device comprises a signal collecting module, a concentrator data transmission module, a signal intensity detection module and a region determining module, wherein the signal collecting module is used for respectively collecting the data transmitted by the ammeter in each region for the corresponding concentrator; the concentrator data transmission module is used for transmitting the data of the ammeter, collected by each concentrator, to the master station; the signal intensity detection module is used for transmitting a command for enabling the two concentrators to respectively detect the intensity of the signal transmitted by the same ammeter when the two concentrators are discovered by the master station to collect the data transmitted by the same ammeter; the region determining module is used for judging that the same ammeter belongs to the region corresponding to the concentrator with high received signal intensity.

Owner:BEIJING XIAOCHENG TECH CO LTD

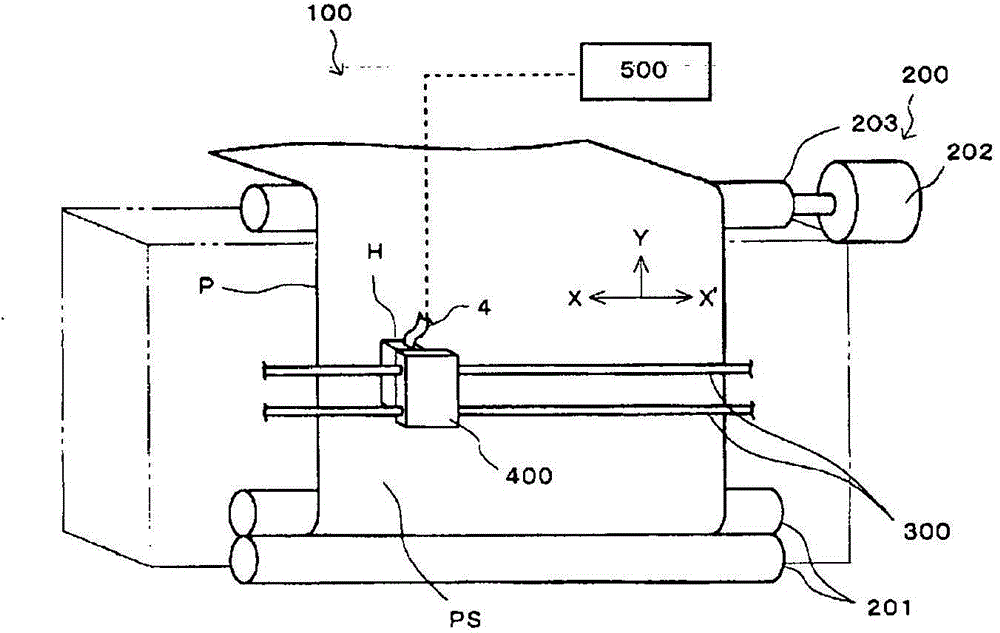

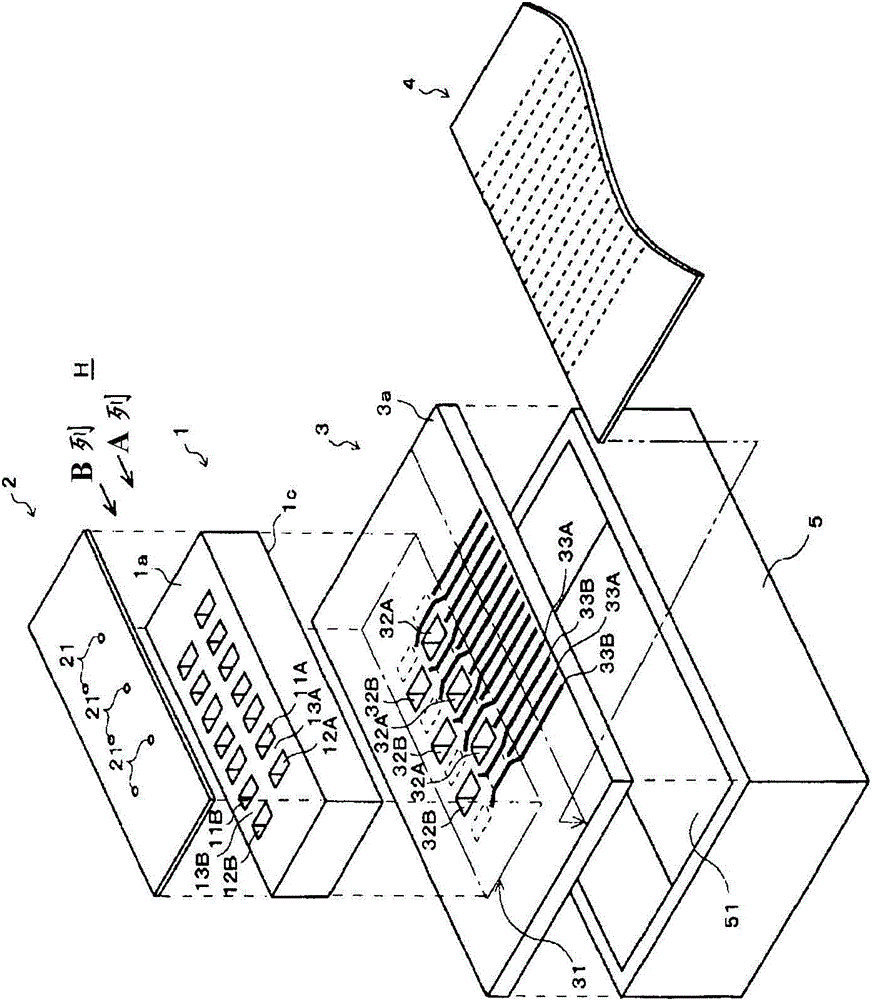

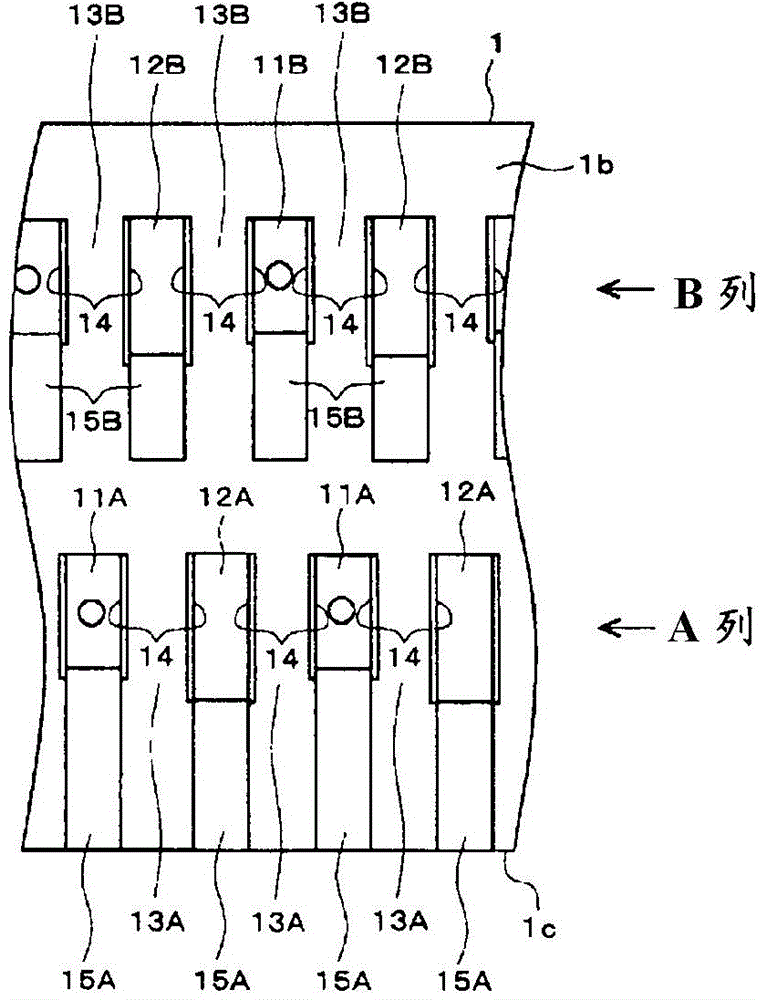

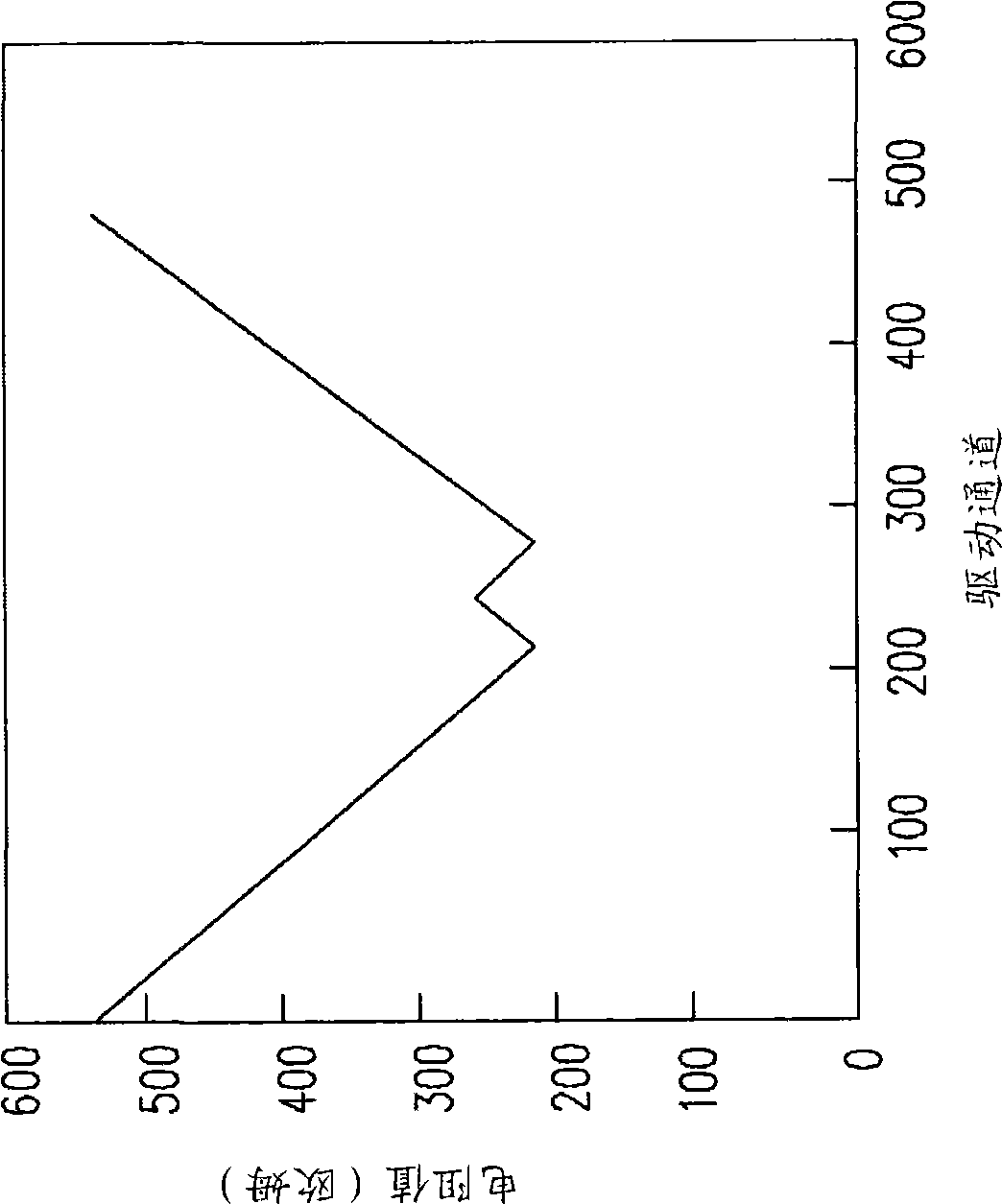

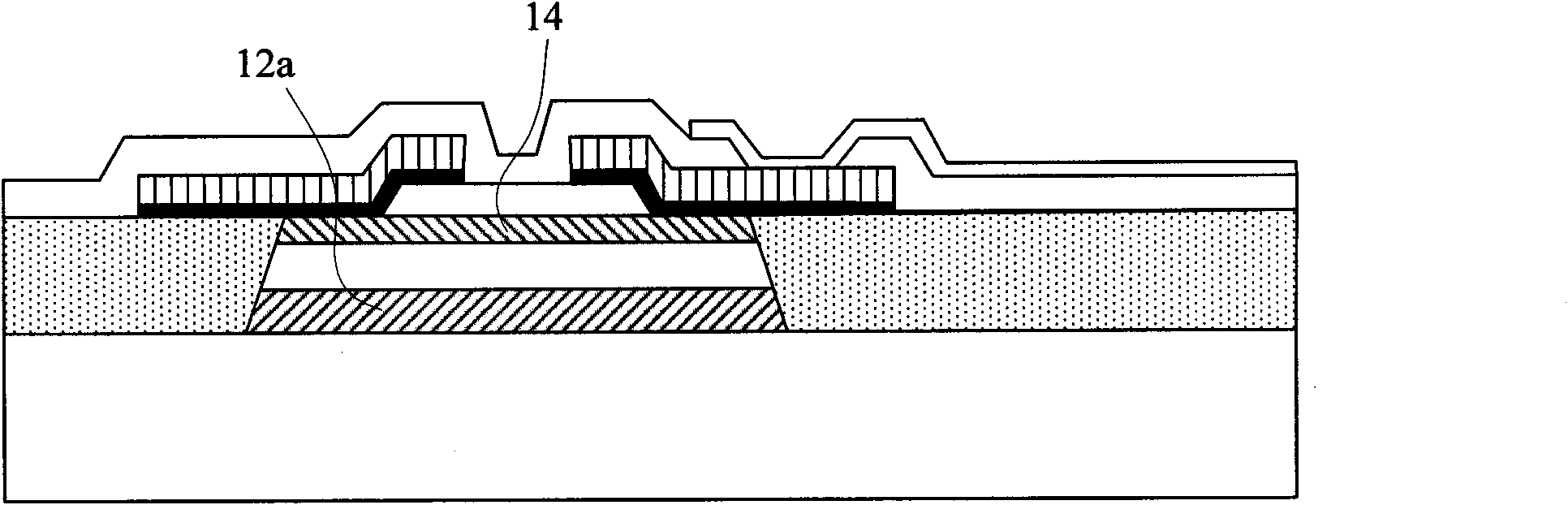

Inkjet head driving method, inkjet head driving device, and inkjet printing device

The purpose of the present invention is to provide an inkjet head driving method, an inkjet head driving device, and an inkjet printing device, which, without making any changes to head structure, can simultaneously reduce drive load and the crosstalk generated between multiple rows of pressure chambers that communicate through a common ink chamber. In an inkjet head comprising two or more rows of pressure chambers for generating the pressure to discharge the ink therein from the nozzles by means of pressure-supplying means that are operated by the application of drive signals and in which the pressure chambers of each row of pressure chambers communicate with each other through a common ink chamber: the rows of pressure chambers are divided into N (N being an integer 2 or greater) drive groups; and between different drive groups, a phase difference of nAL+t (n is an integer 1 or greater, AL is ½ of the acoustic resonance period of the pressure wave in the pressure chambers, and t is the pressure wave transmission time determined from [inter-nozzle distance between drive groups] / [velocity at which sound is conducted through the ink]) is provided for the drive signals that are applied to the pressure-supplying means of the pressure chambers.

Owner:KONICA MINOLTA INC

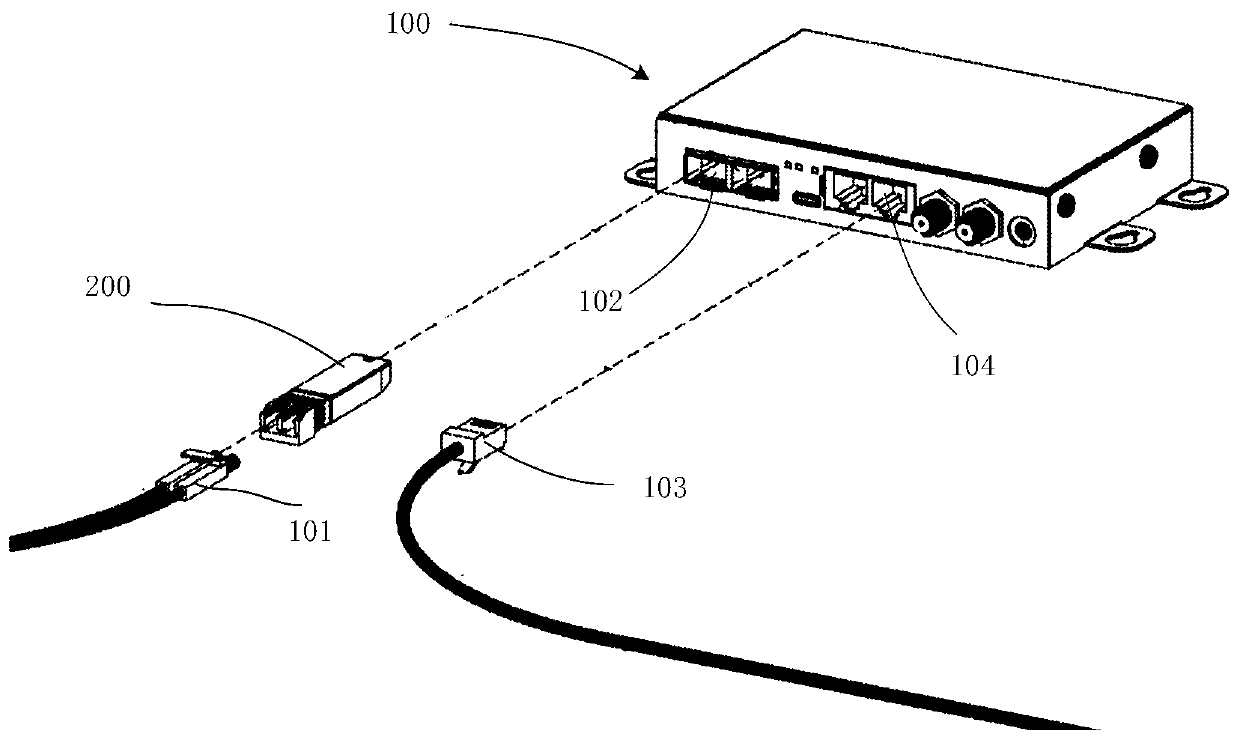

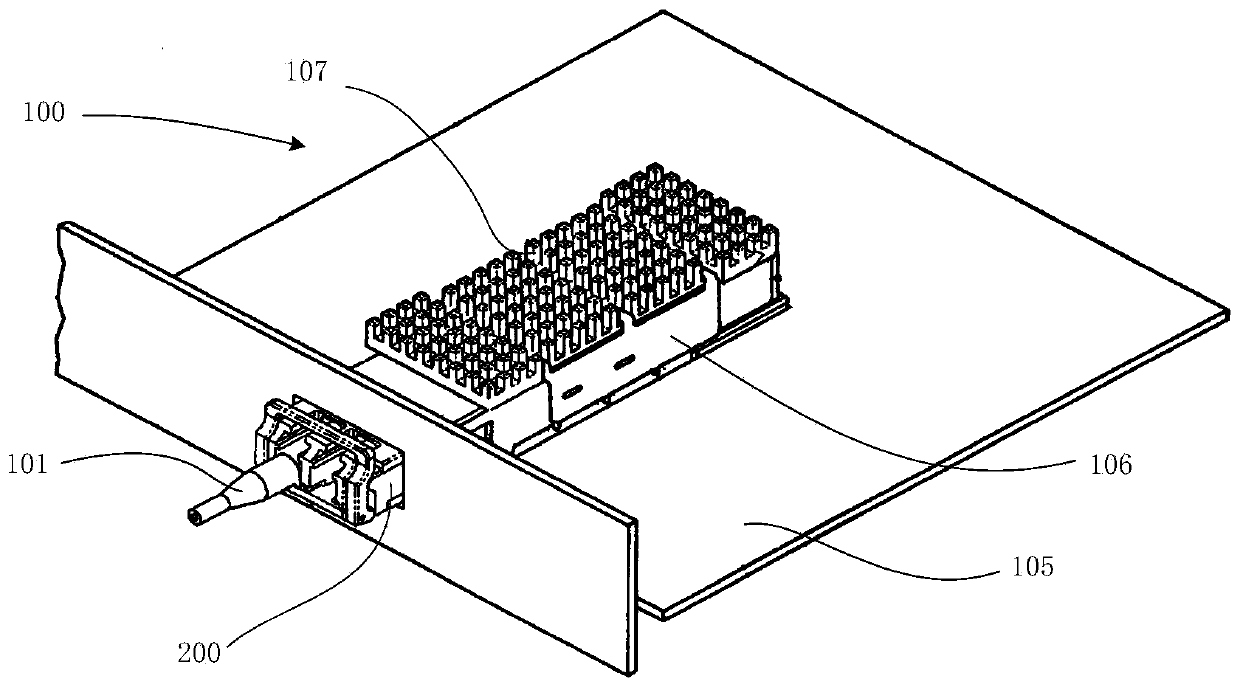

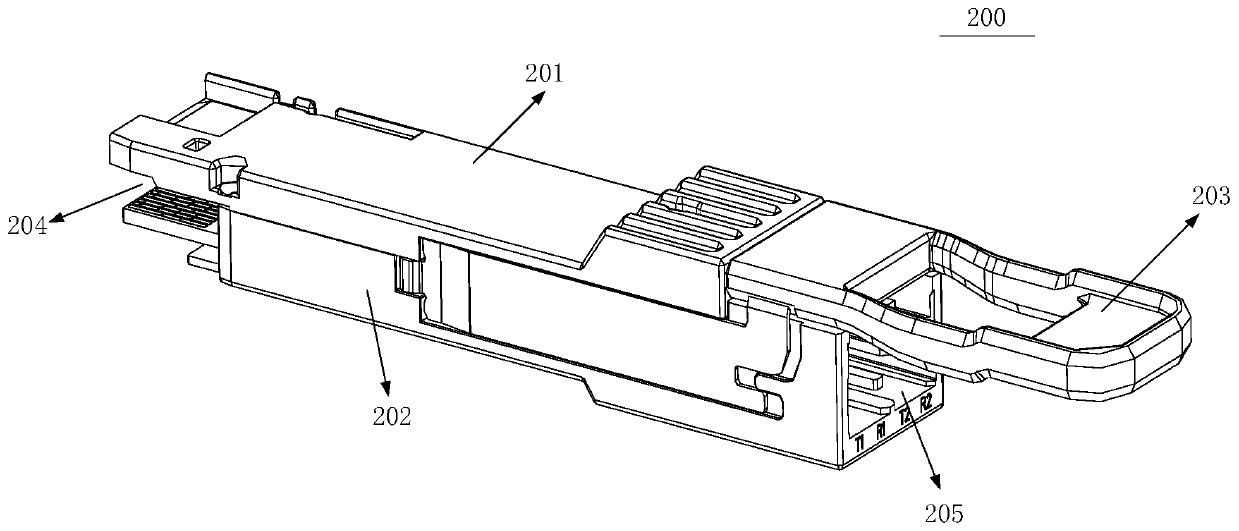

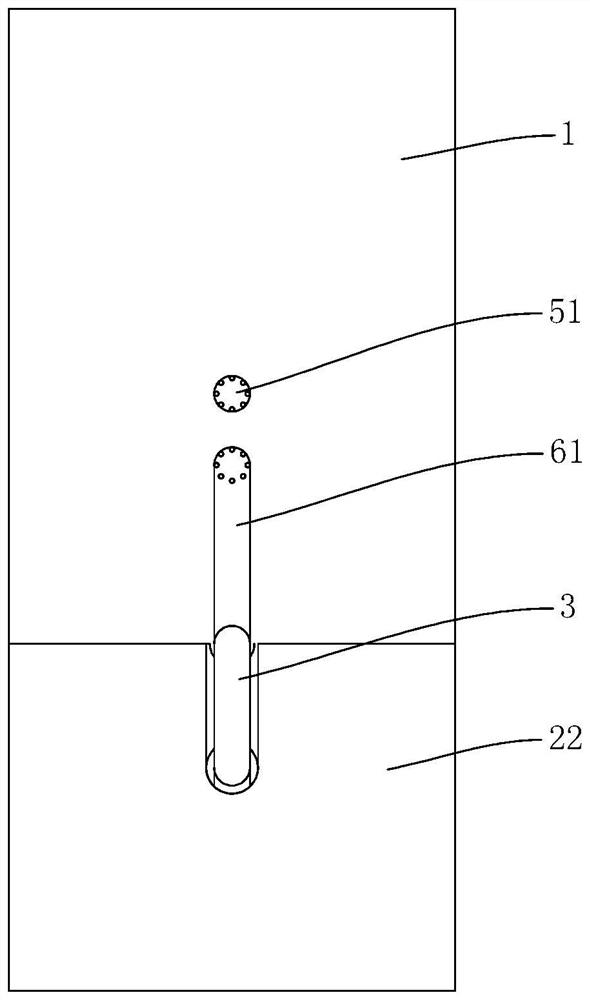

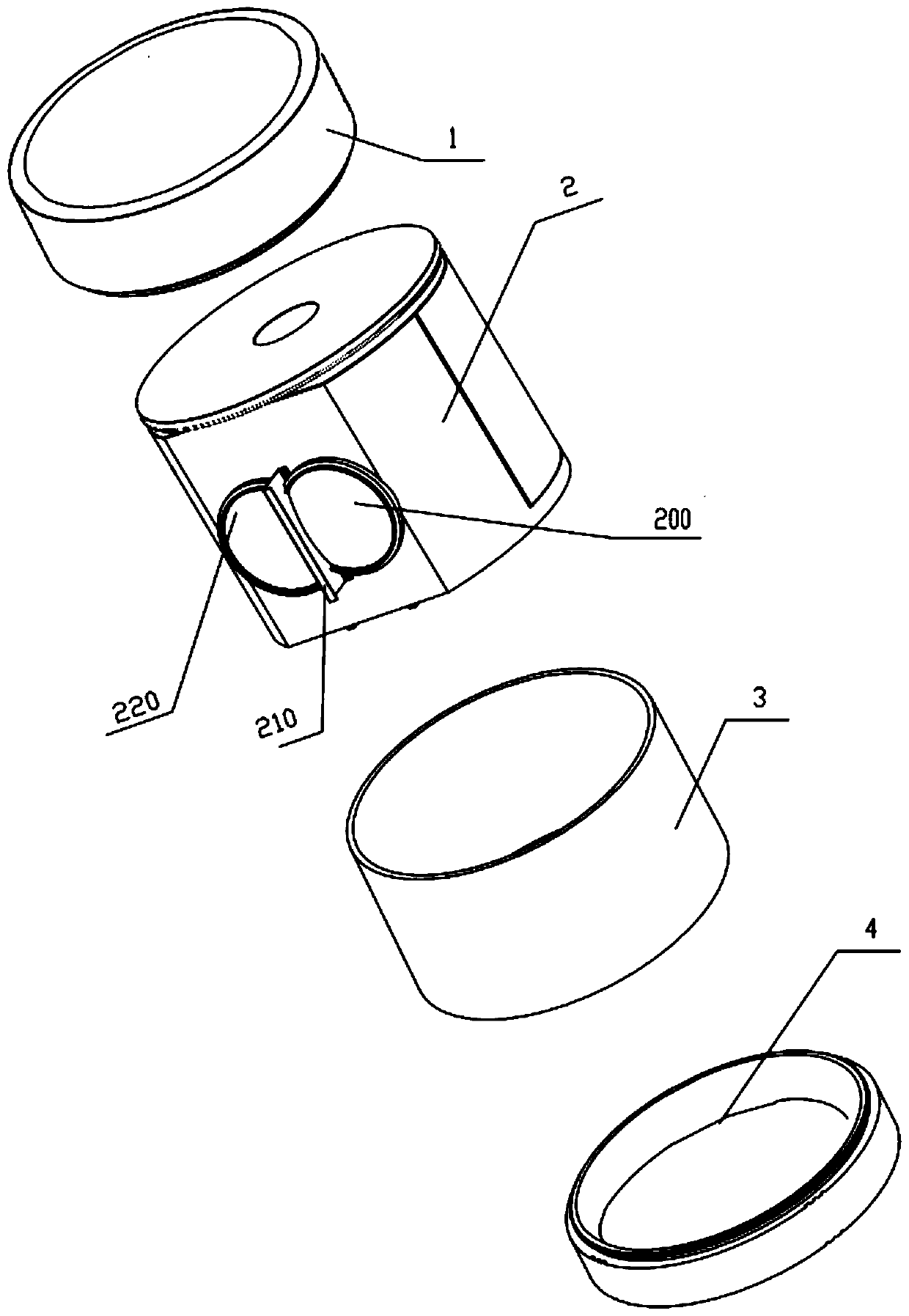

Optical module

ActiveCN111555811ASolve crosstalkPlay an isolation roleElectromagnetic transceiversOptical ModuleHemt circuits

The invention discloses an optical module. The optical module comprises a circuit board; a light emitting assembly which is electrically connected with the circuit board and is used for emitting a light signal; a light receiving assembly which is used for receiving a light signal from the outside of the light module; a flexible board which is used for connecting the light receiving assembly and the circuit board; the light receiving assembly comprises a housing; an optical receiving device which is arranged in the shell and is used for receiving an optical signal of an external optical fiber;and a trans-impedance amplifier which is arranged on the surface of the flexible board inserted into the shell, is connected with the light receiving device, is electrically connected with the circuitboard through the flexible board, and is used for transmitting the amplified electric signal to the circuit board. According to the optical module provided by the invention, the optical receiving assembly is integrated on the flexible board; the optical receiving assembly is connected to the circuit board through the flexible board, chips of the transmitting end and the receiving end are prevented from being integrated on the circuit board, the distance between the transmitting chip and the receiving chip is spatially separated through the external flexible board, and the problem of circuit crosstalk is fundamentally solved by means of spatial isolation, position isolation and the like.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

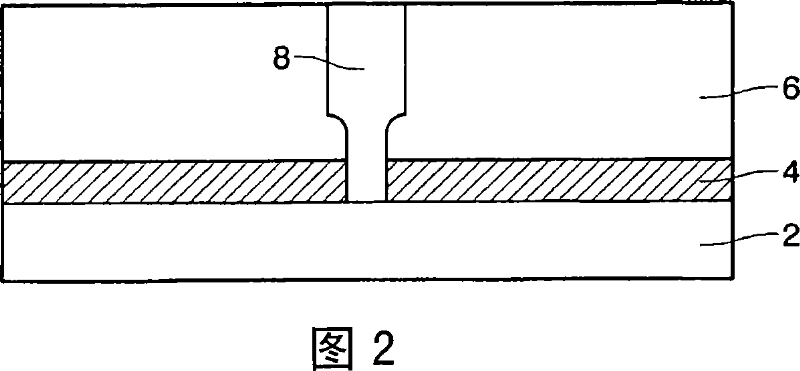

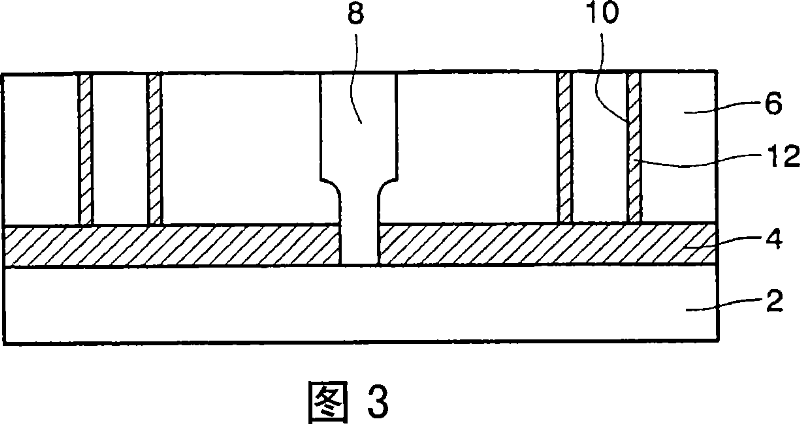

Semiconductor device having a frontside contact and vertical trench isolation and method of fabricating same

InactiveCN101040374AAchieve horizontal decouplingAchieve vertical decouplingSolid-state devicesSemiconductor/solid-state device manufacturingActive layerSemiconductor device

A method of forming a contact post (36) and surrounding isolation trench (28) in a semiconductor-on-insulator (SOI) substrate (20). The method comprises etching a contact hole (26) and surrounding isolation trench (28) from an active layer (6) of the substrate (20) to the insulating layer (4), masking the trench (28) and further etching the contact hole (26) to the base substrate layer (2), filling the trench (28) and contact hole (26) with undoped intrinsic polysilicon (34) and then performing a doping process in respect of the polysilicon material filling the contact hole (26) so as to form in situ a highly doped contact post (36), while the material filling the isolation trench (28) remains non-conductive. The method enables the isolation trench and contact post to be formed substantially simultaneously so as to avoid undue interference with the device fabrication process.

Owner:NXP BV

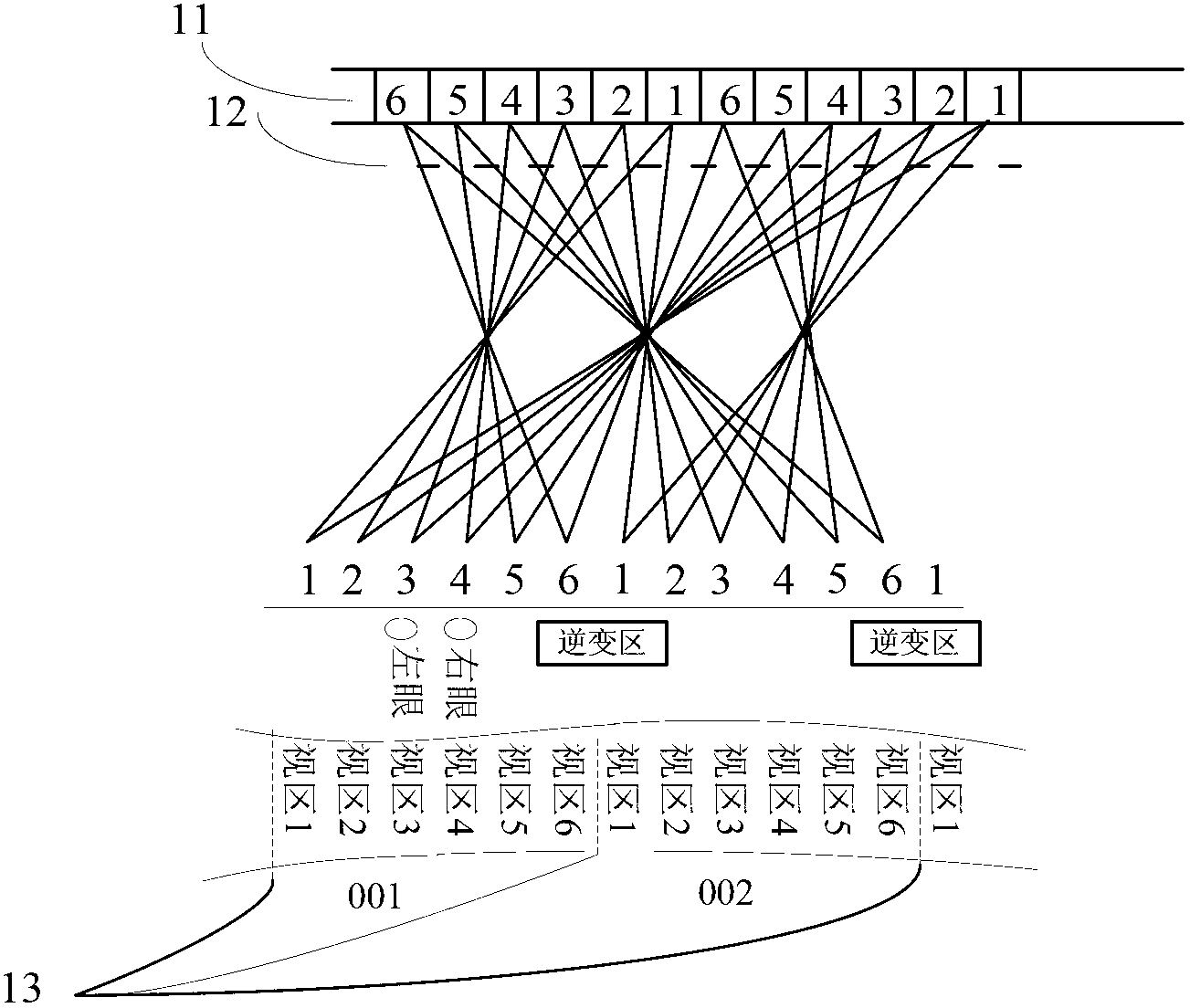

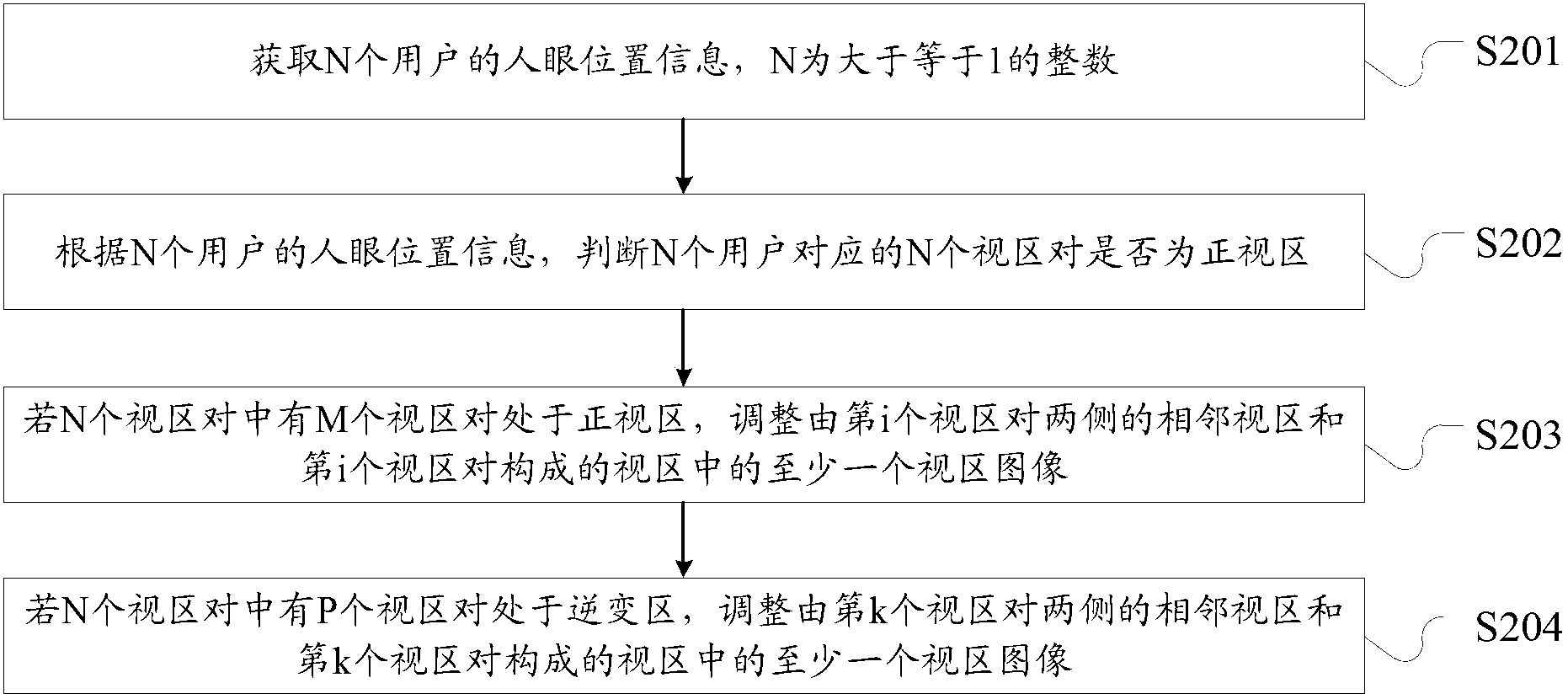

Naked eye three-dimensional (3D) image processing method and device

ActiveCN103067728ASolve crosstalkSolve the ghosting problemSteroscopic systemsImaging processingComputer science

The invention discloses a naked eye three-dimensional (3D) image processing method and a naked eye 3D image processing device. The method is applied to electronic display equipment, and comprises the steps of acquiring human eye position information of N users, wherein N is an integer of more than or equal to 1; judging whether N visual area pairs which correspond to the N users are in a front view area according to the human eye position information of N users; adjusting at least one visual area image in a visual area formed by adjacent visual areas and the ith visual area pair on two sides of the ith visual area pair if M visual areas in the N visual area pairs are positioned in the front view area, wherein M is more than or equal to 1 and less than or equal to N, i is more than or equal to 1 and less than or equal to M, and i and M are integers; and adjusting at least one visual area image in a visual area formed by adjacent visual areas and the kth visual area pair on two sides of the kth visual area pair if p visual areas in the N visual area pairs are positioned in an inversion area, wherein P is more than or equal to 1 and less than or equal to N, k is more than or equal to 1 and less than or equal to M, and k and P are integers.

Owner:HISENSE VISUAL TECH CO LTD

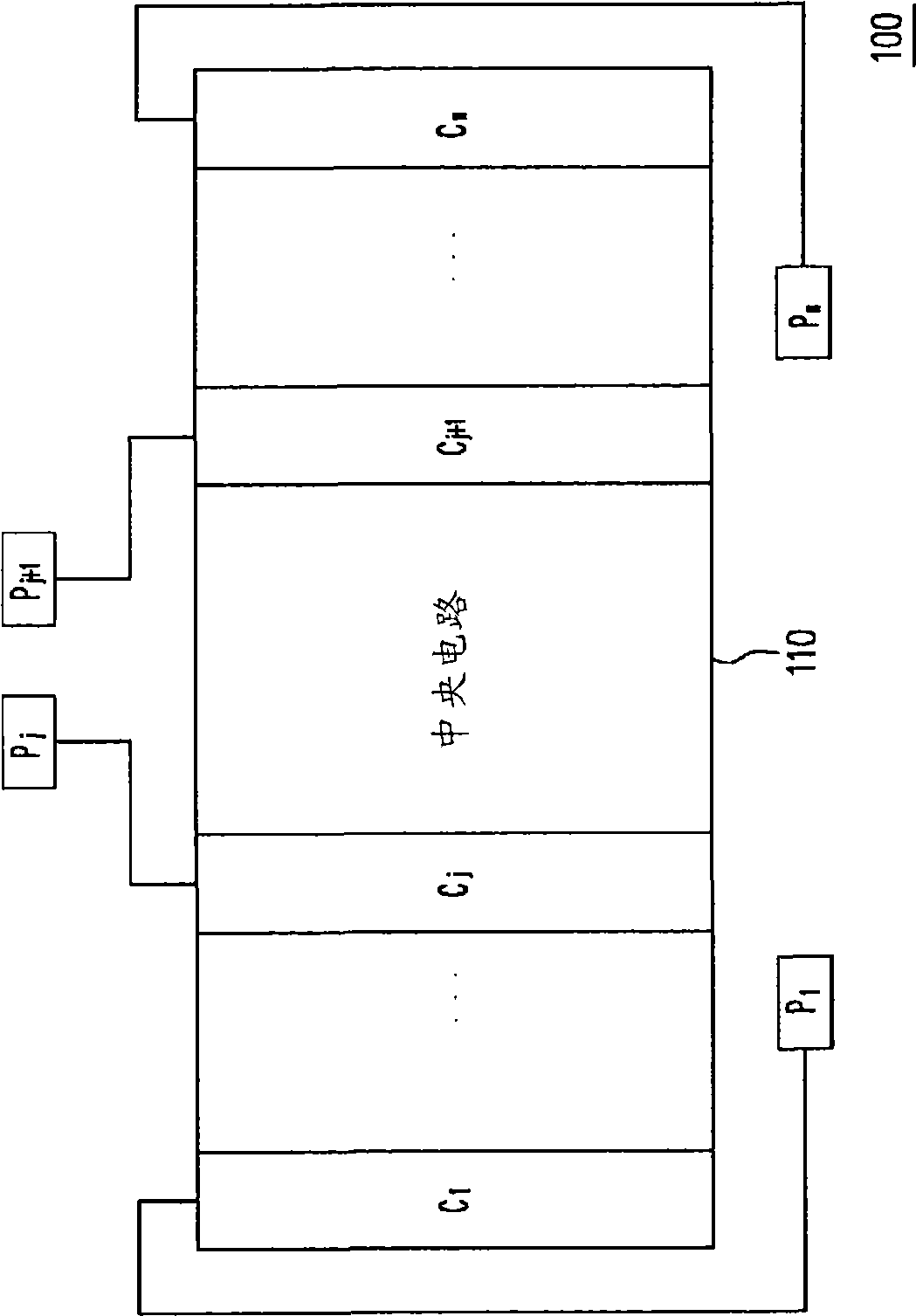

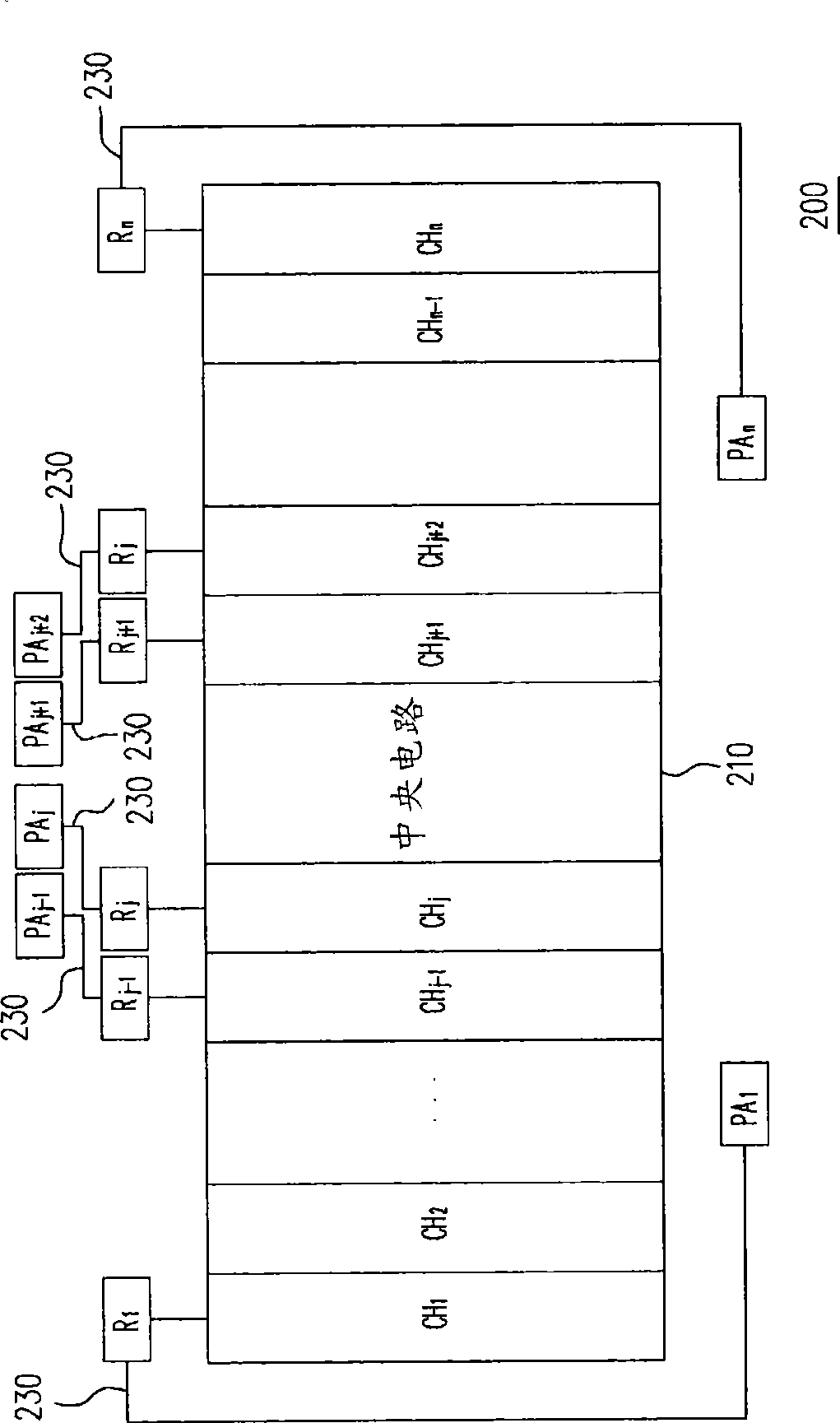

Layout structure of source driver and method thereof

InactiveCN101510017ASolve for uniformitySolve crosstalkStatic indicating devicesNon-linear opticsElectrical resistance and conductanceEngineering

A layout structure of a source driver having a plurality of driving channels, and a method thereof are provided herein. The layout structure of the source driver includes a plurality of pads and a plurality of routings. The pads are used for making electric contact between the source driver and an external circuit. The routings are respectively coupled between the driving channels and the pads for transmitting the signal. Besides, the routings respectively includes a plurality of resistance units, and each of the resistance units is used for adjusting the resistance of the respective routing so as to minimize a variation of the driving ability between the pads.

Owner:HIMAX TECH LTD

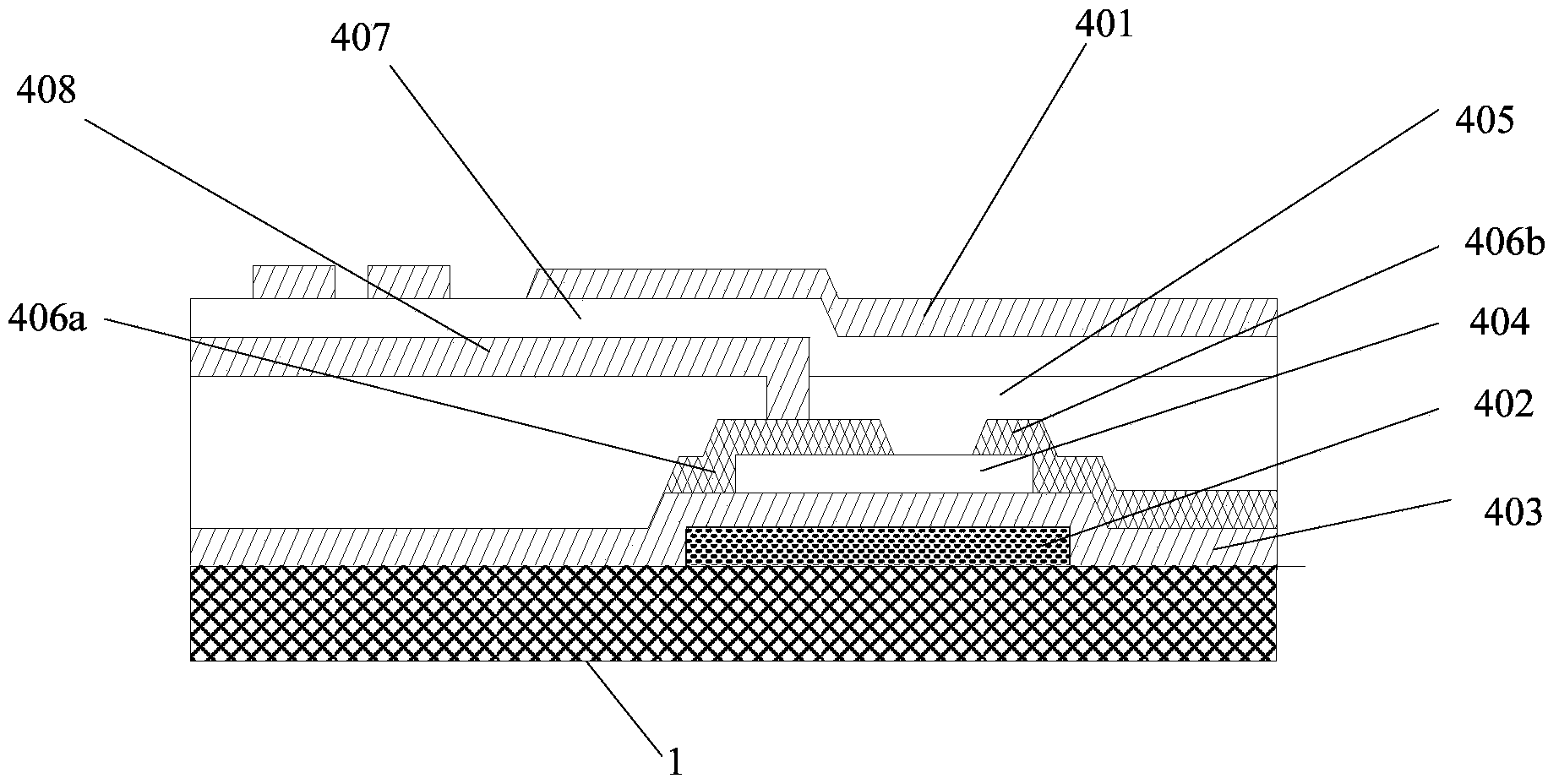

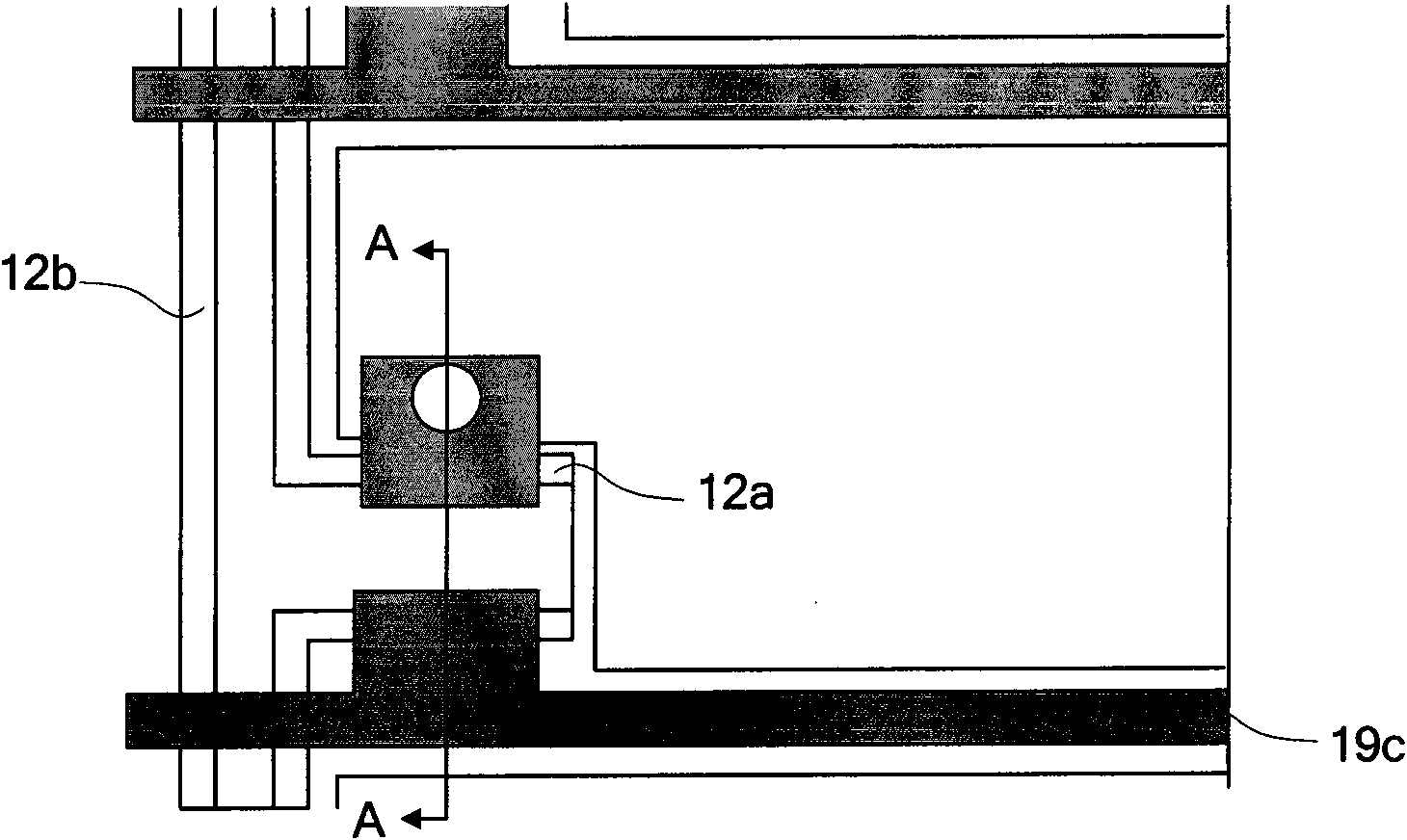

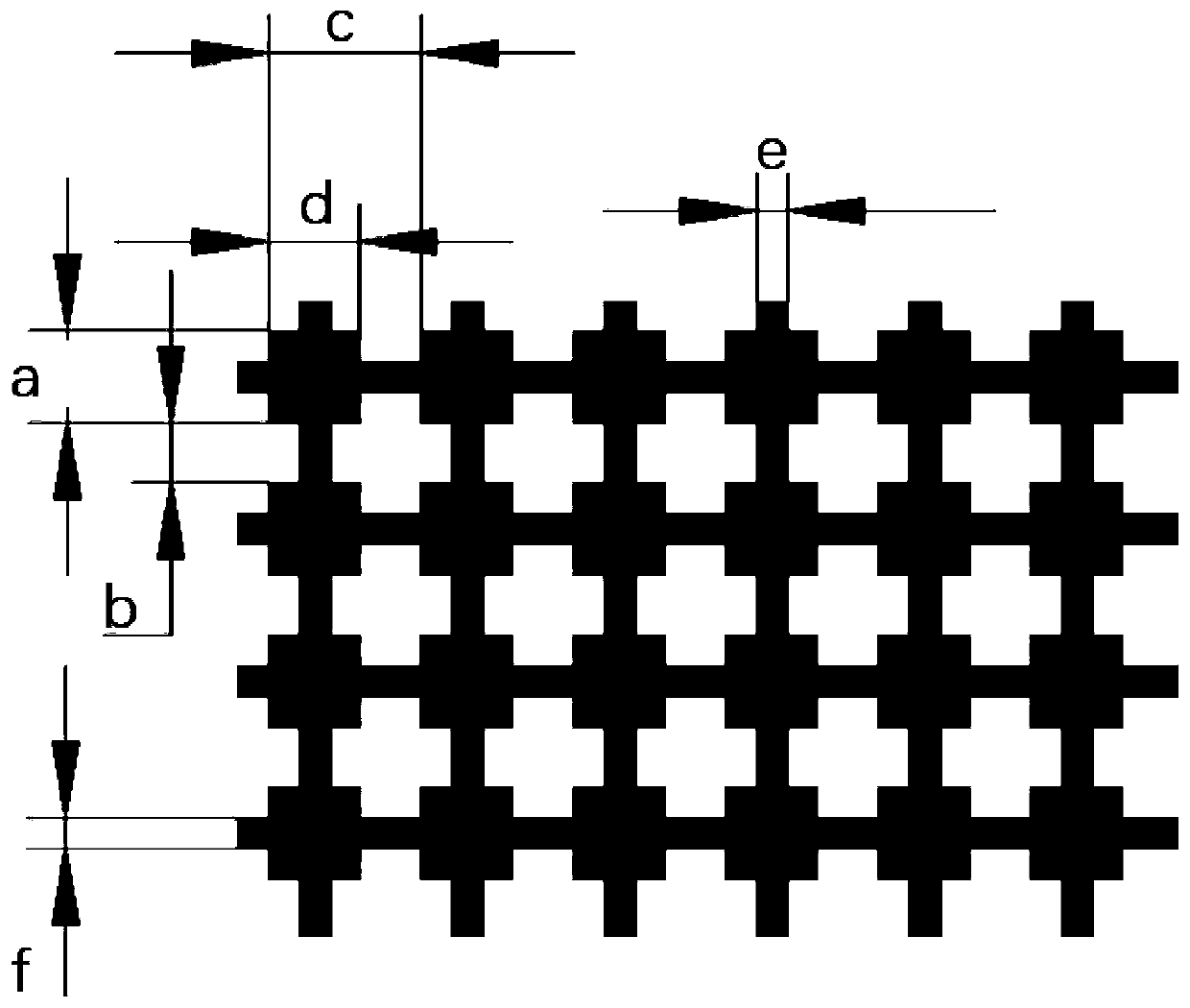

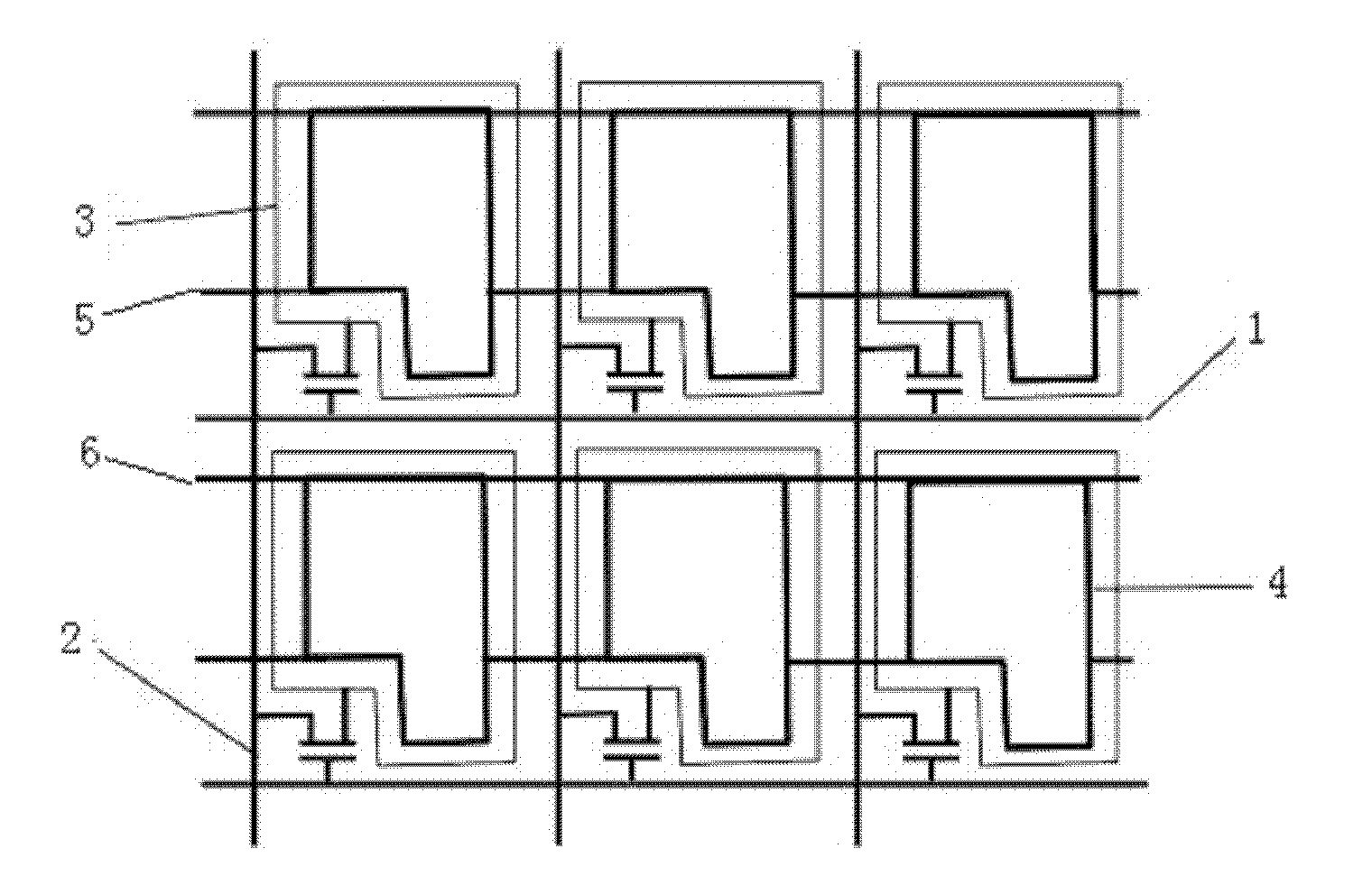

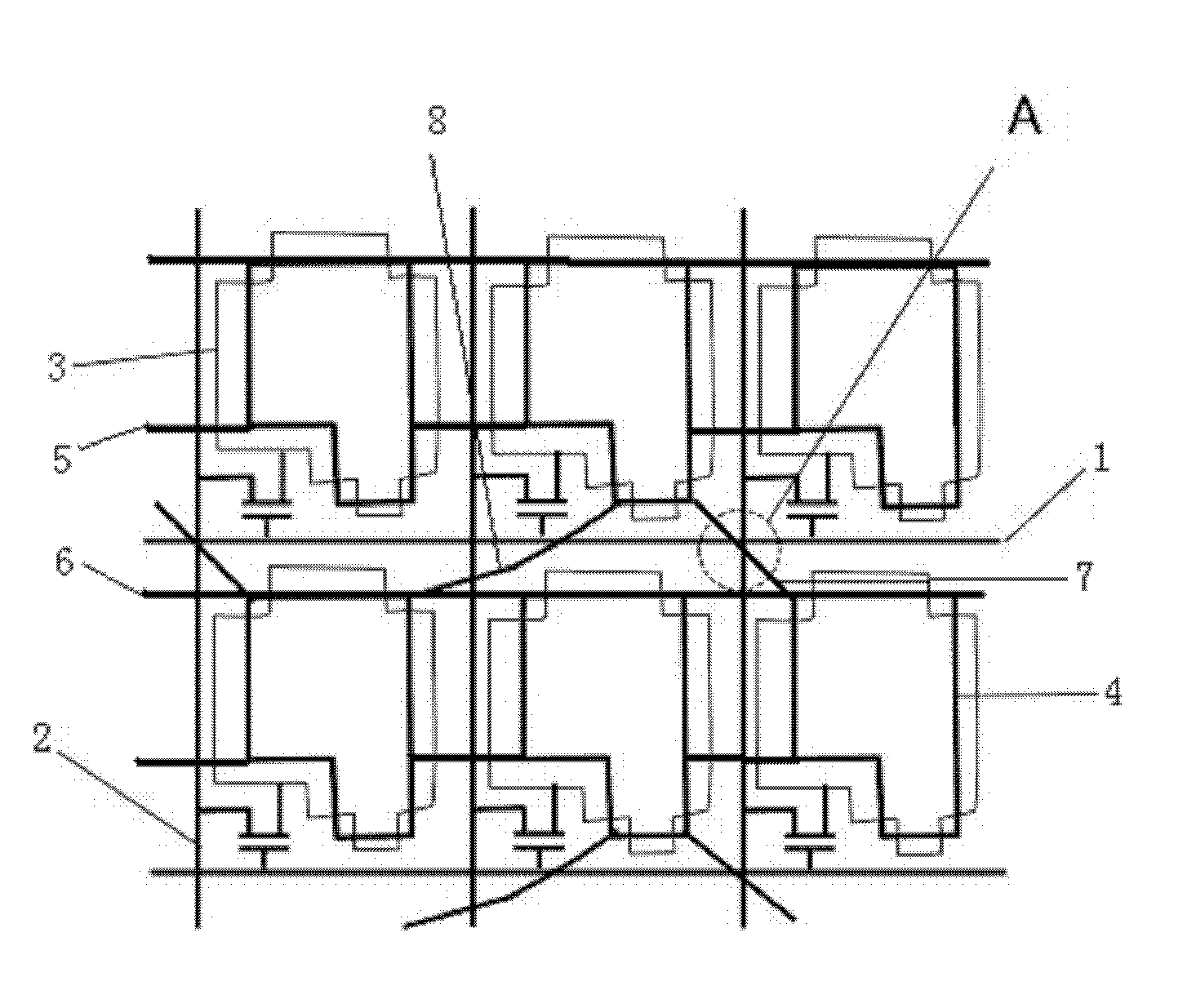

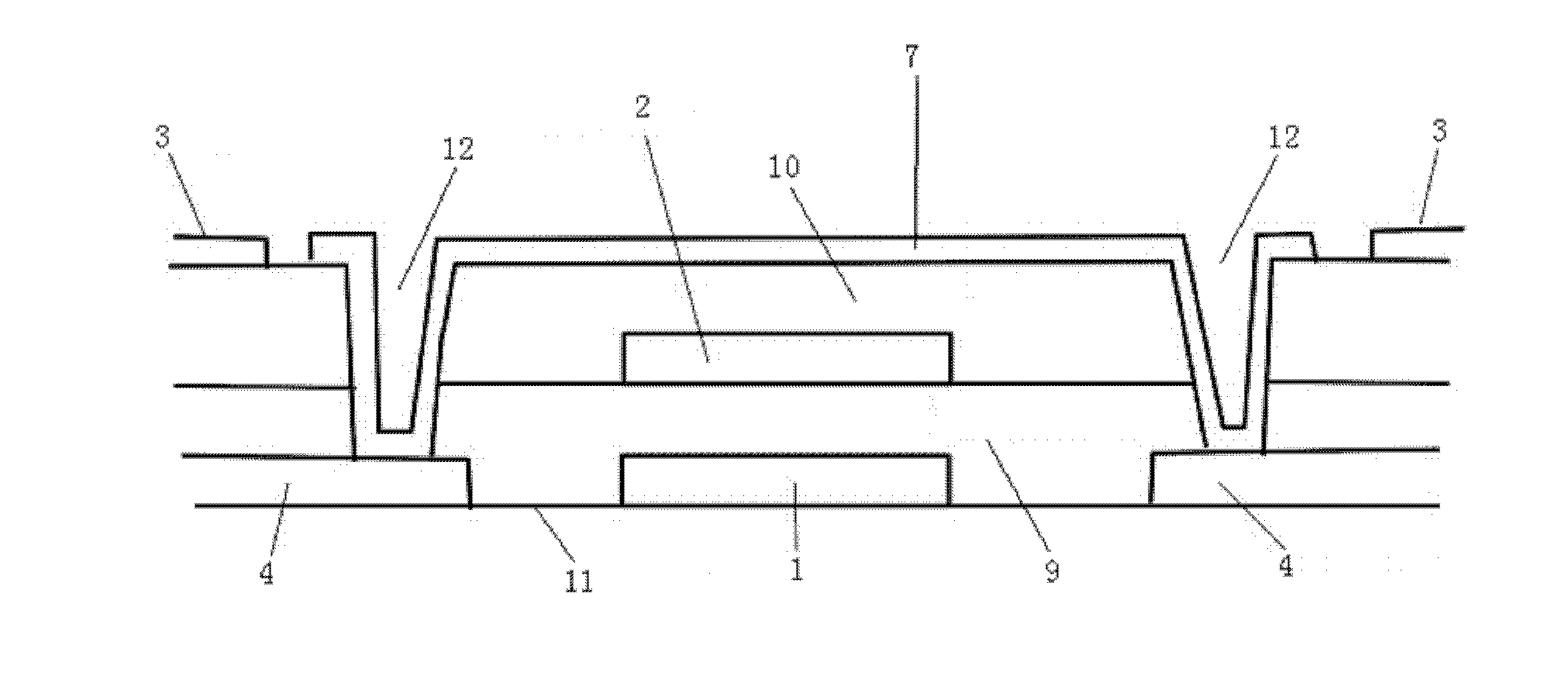

TFT (Thin Film Transistor) array structure and manufacturing method thereof

InactiveCN101894845AImprove yieldSolve crosstalkSemiconductor/solid-state device detailsSolid-state devicesEngineeringDistortion

The invention provides a TFT array structure and a manufacturing method thereof. The TFT array structure comprises a base plate, a grid line and a common electrode which are formed on the base plate, data lines crossed with the grid line, insulating layers formed on the common electrode and the base plate, and TFTs formed on the intersections of the grid line and the data lines, wherein each TFT comprises a grid forming into a whole with the grid line, a grid insulating layer and a semiconductor layer which are sequentially formed on the grid, a drain electrode and a source electrode forming into a whole with the data lines; the semiconductor layer on the grid line between the intersections of two data lines and the grid line is at least partially etched. Therefore, when voltage signals of the two data lines are different, current does not flow between the two data lines. By the invention, the manufacturing cost of the TFT array structure can be reduced; the problems of crosstalk and distortion between the data lines are solved; and the yield is enhanced advantageously.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

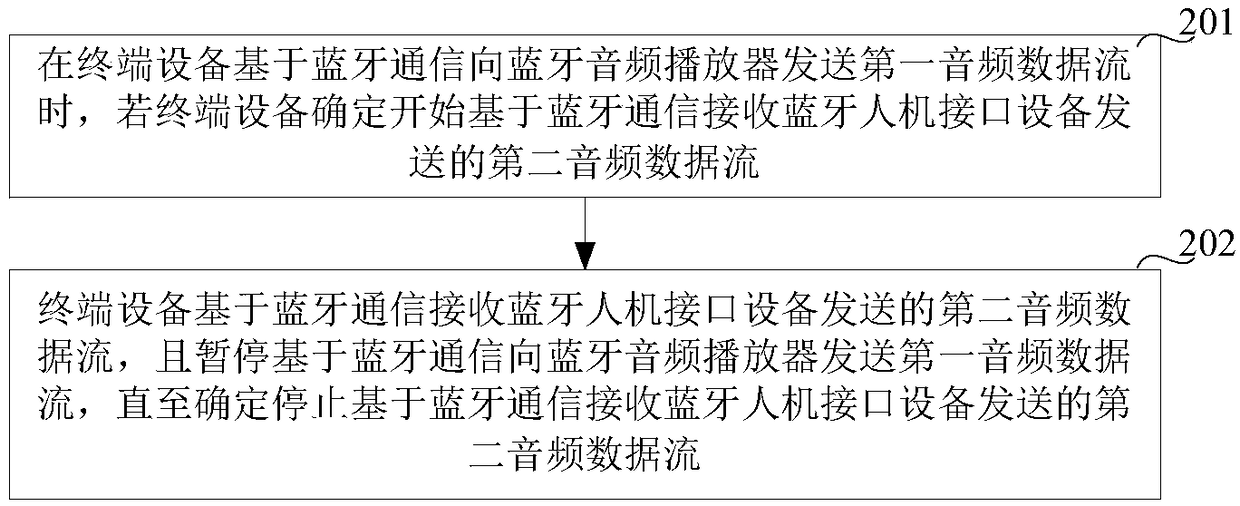

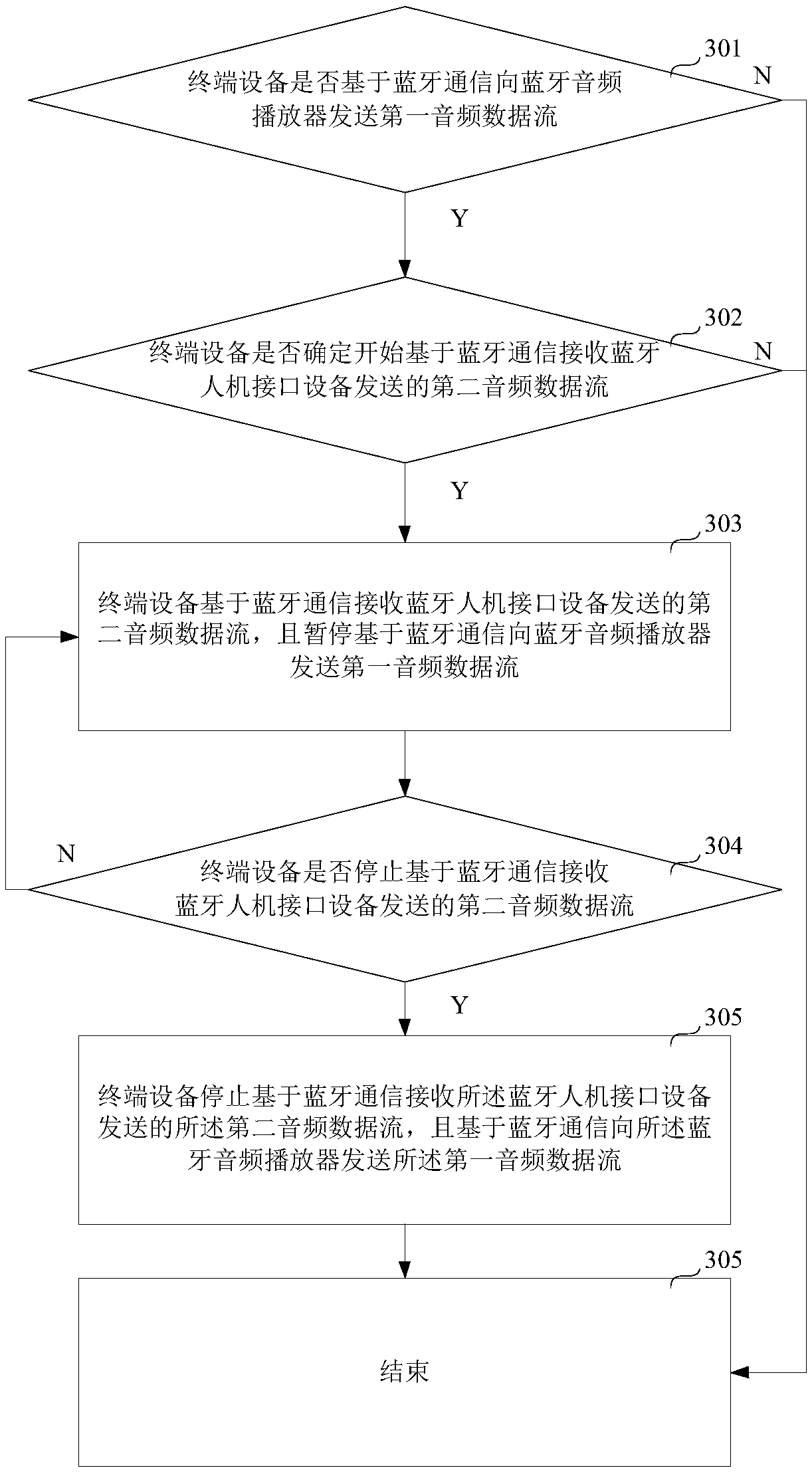

Audio data processing method based on Bluetooth communication, terminal device, and storage medium

ActiveCN109451346ASolve crosstalkImprove transmission qualitySelective content distributionShort range communication serviceData streamTerminal server

The embodiment of the invention relates to the field of Bluetooth communication, and particularly to an audio data processing method based on Bluetooth communication, a terminal device, and a storagemedium for solving the problem of sound crosstalk generated during the transmission of multiple audio data by the terminal device and the problem of high packet loss rate of the audio data sent by a Bluetooth human-computer interface. In the embodiment of the invention, since a first audio data stream transmitted between the terminal device and a Bluetooth audio player is suspended in a process when the terminal device and a Bluetooth human-computer interface device transmit a second audio data stream, the problem of sound crosstalk can be solved. Further, since the processing capability of the Bluetooth communication technology is limited, when the first audio data stream is suspended during the transmission of the second audio data stream, the transmission quality of the second audio data stream can be improved, and the packet loss rate of the audio data sent by the Bluetooth human-computer interface device can be reduced, so that the voice recognition rate of the second audio data stream can be improved.

Owner:HISENSE VISUAL TECH CO LTD

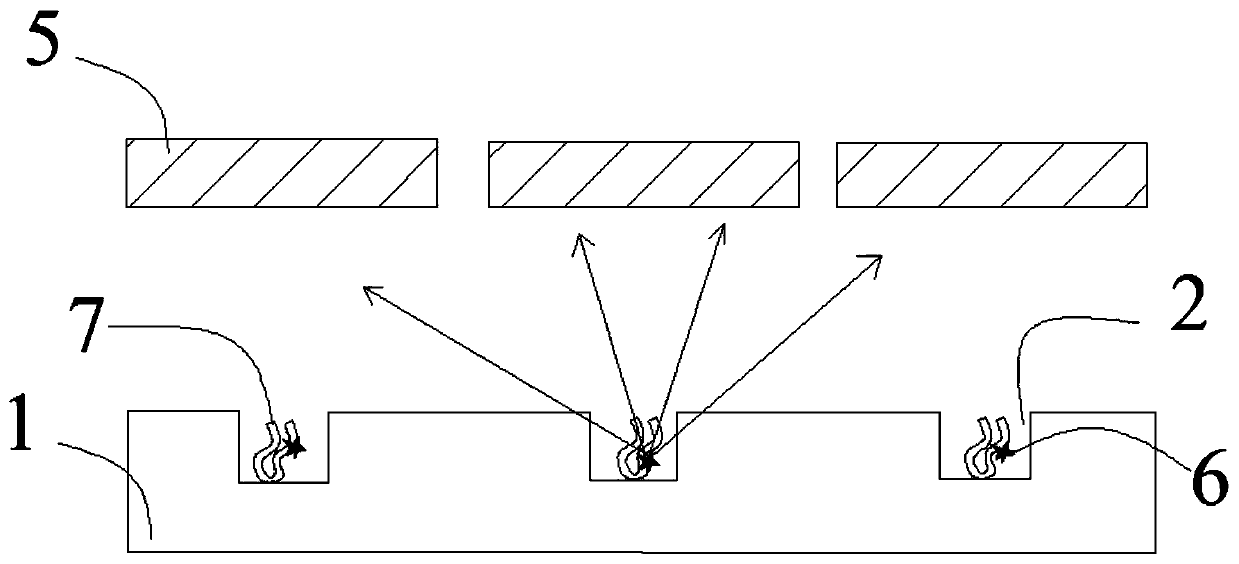

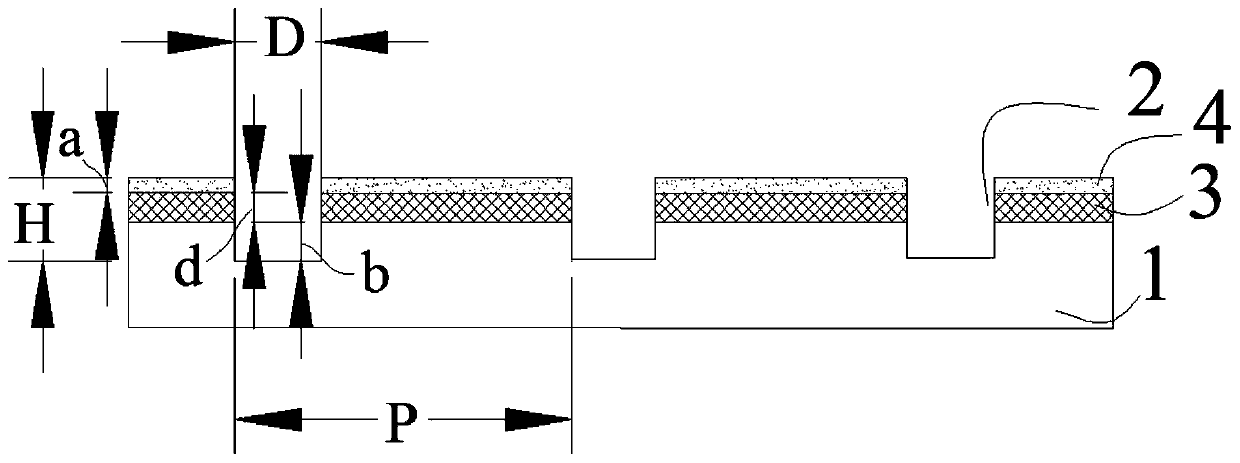

Gene sequencing chip, equipment and manufacturing method

PendingCN110066723ASolve crosstalkBioreactor/fermenter combinationsBiological substance pretreatmentsBlock structureGene

The invention provides a gene sequencing chip, equipment and a manufacturing method, and belongs to the technical field of gene sequencing. The problem that for an existing gene sequencing chip, crosstalk exists in application can be at least partially solved. The gene sequencing chip comprises a base and multiple micro-porous structures arranged on the base, and light-blocking structures are arranged between the adjacent micro-porous structures and used for blocking light emitted from the hole bottoms of the micro-porous structure from shining to detection units corresponding to the adjacentlight-blocking structures.

Owner:BOE TECH GRP CO LTD

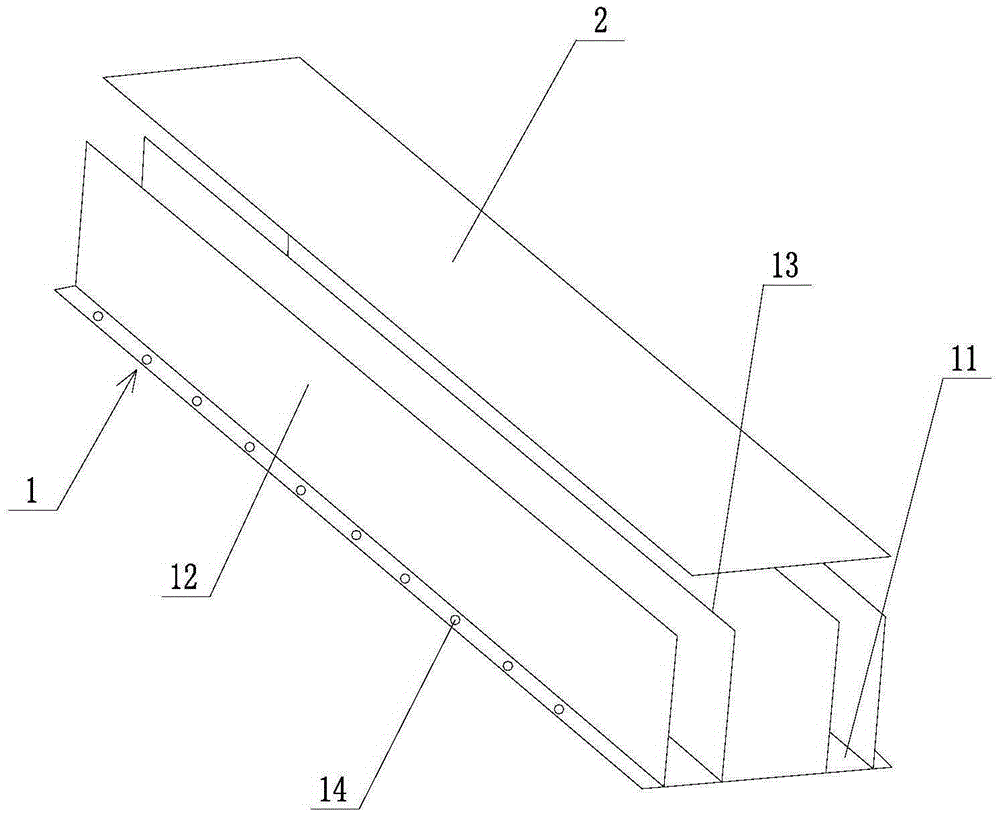

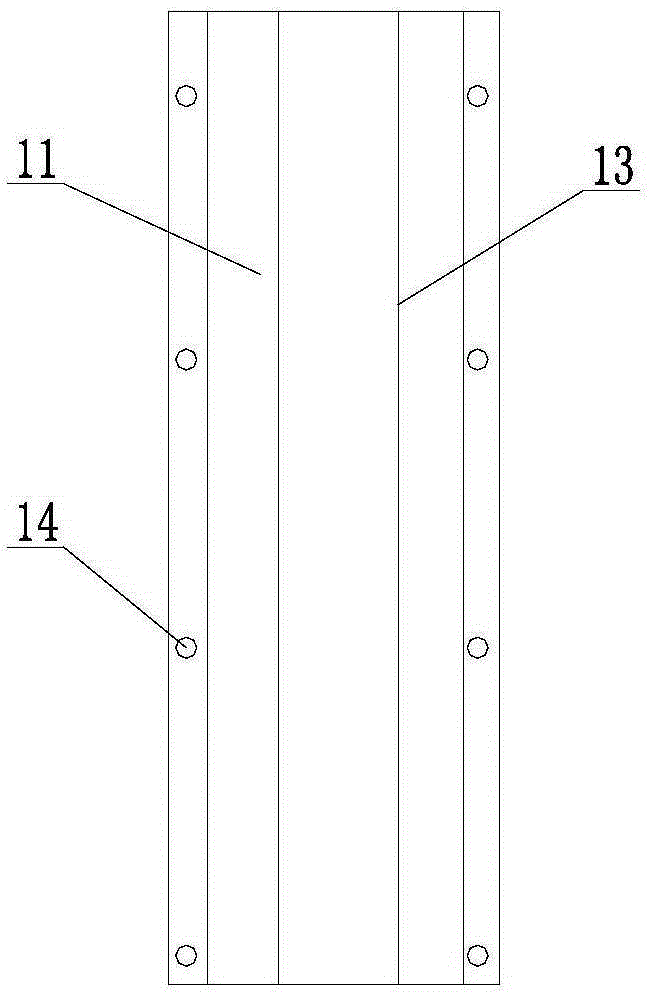

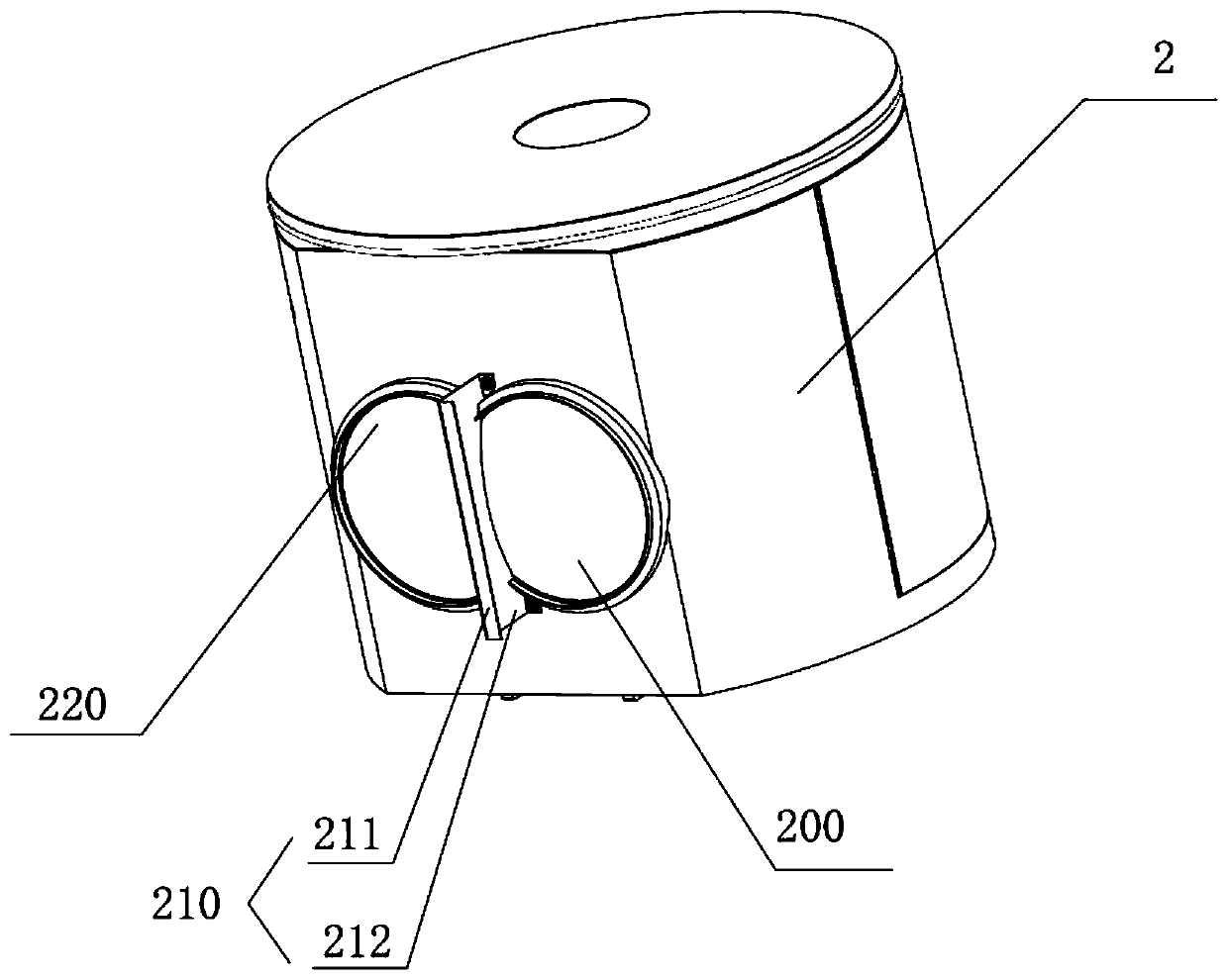

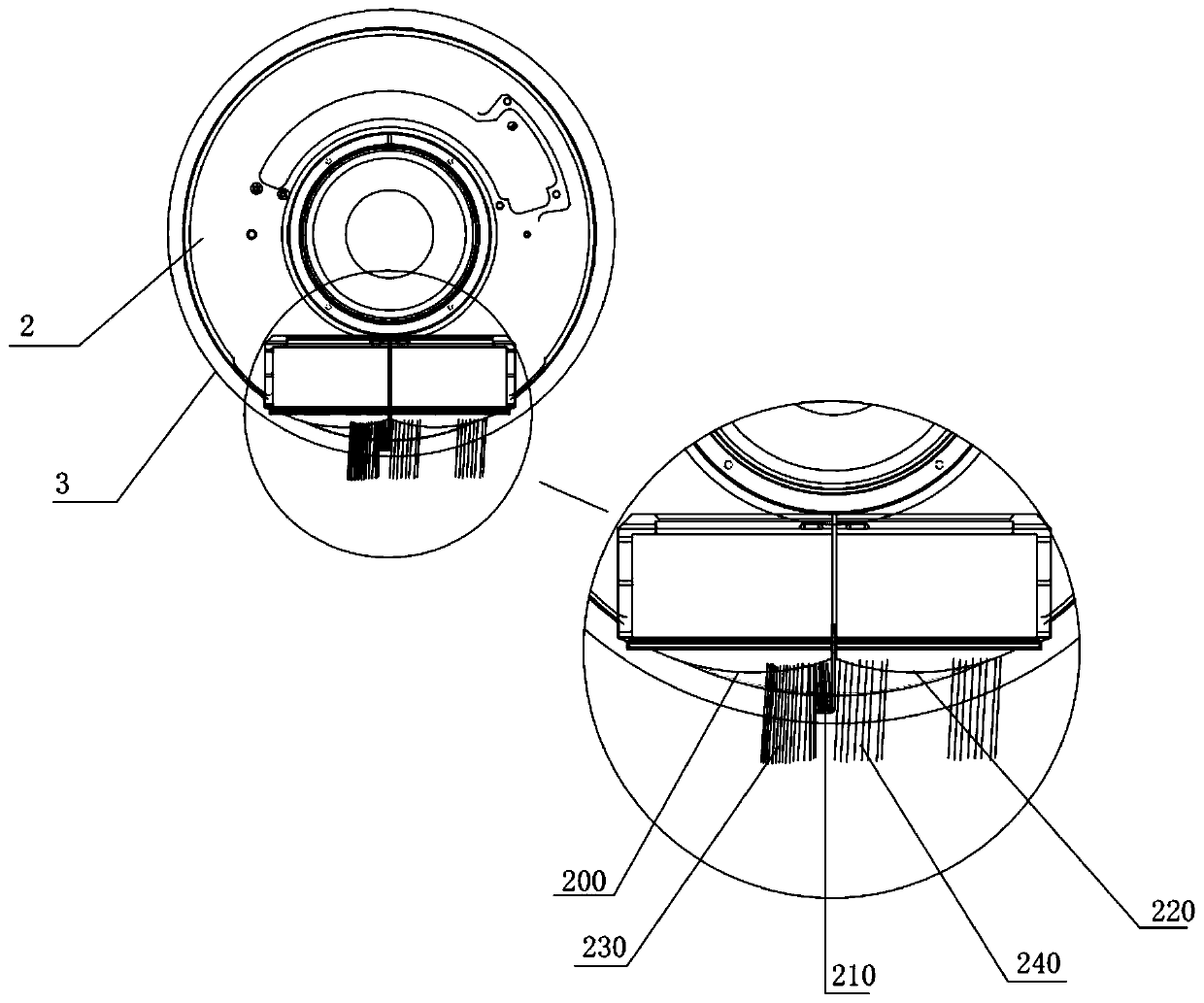

Cabinet routing box and electric appliance cabinet

InactiveCN105338769AImprove shielding effectSolve crosstalkCircuit arrangements on support structuresCasings/cabinets/drawers detailsEngineeringCrosstalk

The invention relates to the technical field of routing devices of electric appliance cabinets and in particular relates to a cabinet routing box. The cabinet routing box comprises a routing trough and a cover plate, wherein the cover plate is connected with the routing trough in a clamping manner. The cabinet routing box is fixedly connected with a groundable cabinet shell. Meanwhile, the invention also relates to an electric appliance cabinet on which the cabinet routing box is installed. The cabinet routing box has the beneficial effects that the cabinet routing box has the effects of effectively solving the problem of crosstalk among various cables in existing cabinet routing modes, improving the EMC (electromagnetic compatibility) characteristic of internal cables and shortening the EMC test period and has good mechanical protection and electric protection functions; meanwhile, as the cover plate and routing trough of the cabinet routing box are connected in a clamping manner, the cabinet routing box has a simple structure and is convenient to machine, disassemble and maintain.

Owner:GREE ELECTRIC APPLIANCES INC

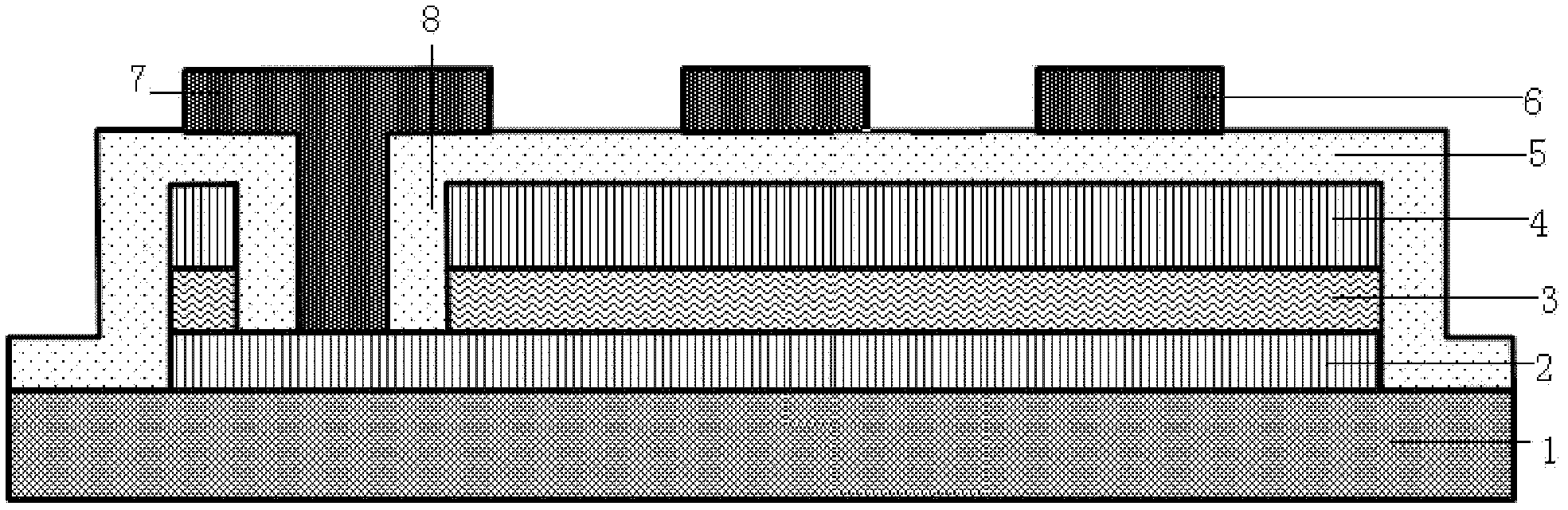

Anti-crosstalk flexible transparent memory array and preparation method thereof

InactiveCN102569337ADoes not involve high temperatureReduce energy consumptionSolid-state devicesSemiconductor/solid-state device manufacturingElectronic systemsOrganic semiconductor

The invention discloses an anti-crosstalk flexible transparent memory array and a preparation method of the array. An organic diode is used as a drive pipe, the preparation technology is simple, the occupied area is small and the array is convenient to reduce with equal ratio. In the invention, flexible transparent material is adopted, thus the array has the intrinsic characteristic of a variable resistance memory, also has the advantages of being flexible and transparent, especially solves the problem of crosstalk in the integrated array of the memory; and the prepared memory array can be widely used in electronic paper, flexible transparent display and other related electronic systems. The organic material is used for replacing the traditional expensive heavy silicon and other inorganic materials and the memory array is a green environmental protection device adapted to the future development and also has the advantages of being light in weight and low in cost of the organic semiconductor material, and the device has a fully transparent structure and produced on a transparent device or article by a transparent encapsulation process and especially promotes the display technology of a new generation.

Owner:PEKING UNIV

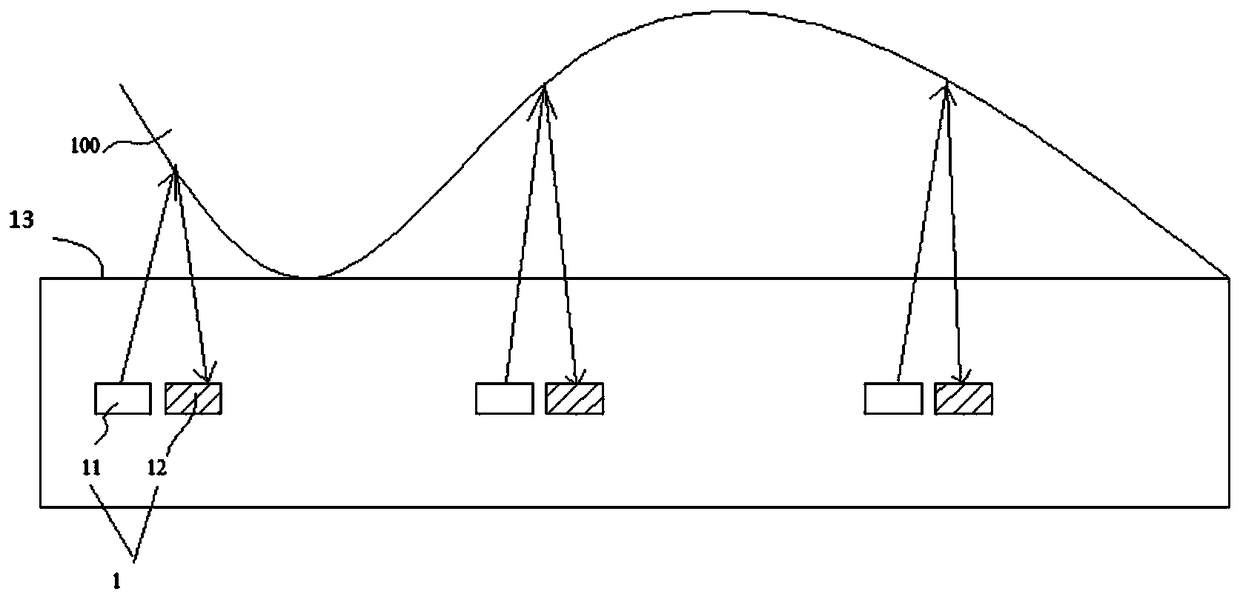

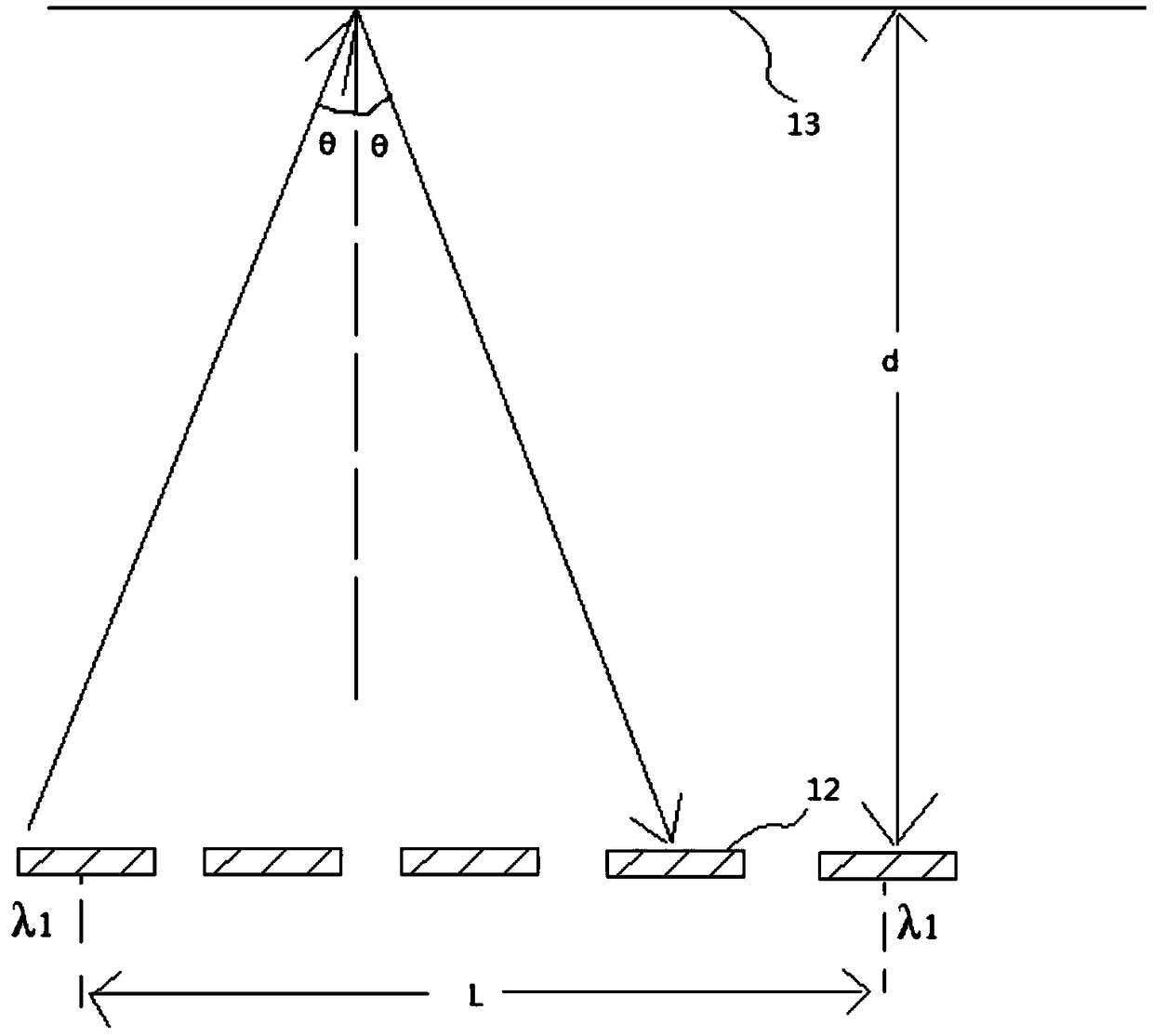

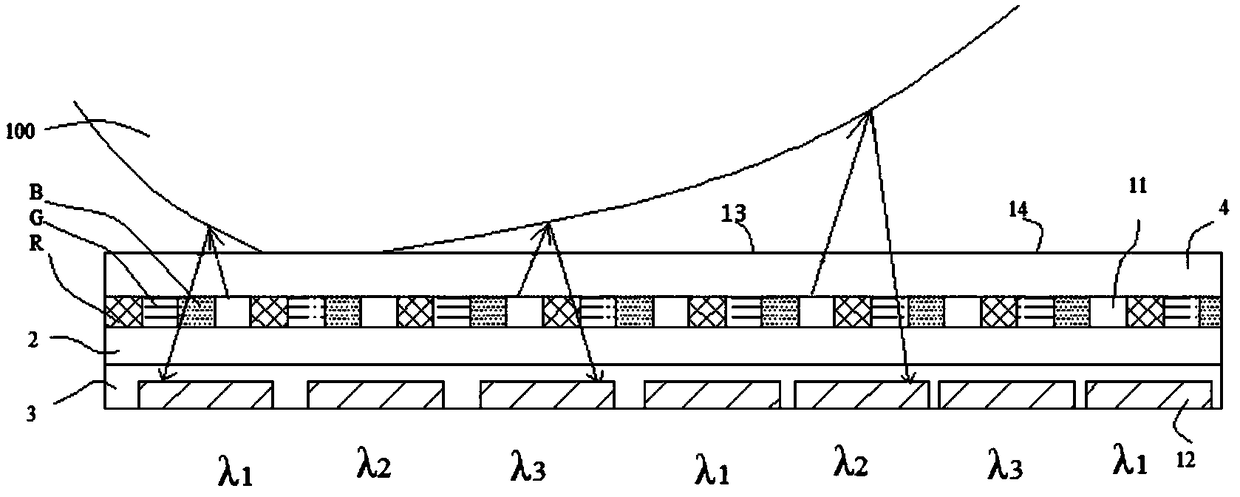

Fingerprint identification structure and display panel

The invention provides a fingerprint identification structure and a display panel, belongs to the fingerprint identification and display technical field, and can partially solve the problems that an existing fingerprint identification structure is easy to have crosstalk. The fingerprint identification structure comprises a plurality of identification units arranged in an array; each identificationunit comprises an emission module and a sensing module; the sensing module is arranged in a position capable of receiving lights emitted by the emission module and reflected by the fingerprint; in each identification unit, the sensing module can sense that the light wavelength is equal to that of the light emitted by the emission module; the wavelengths of lights emitted by the emission modules in at least partial the adjacent identification units are different.

Owner:BOE TECH GRP CO LTD +1

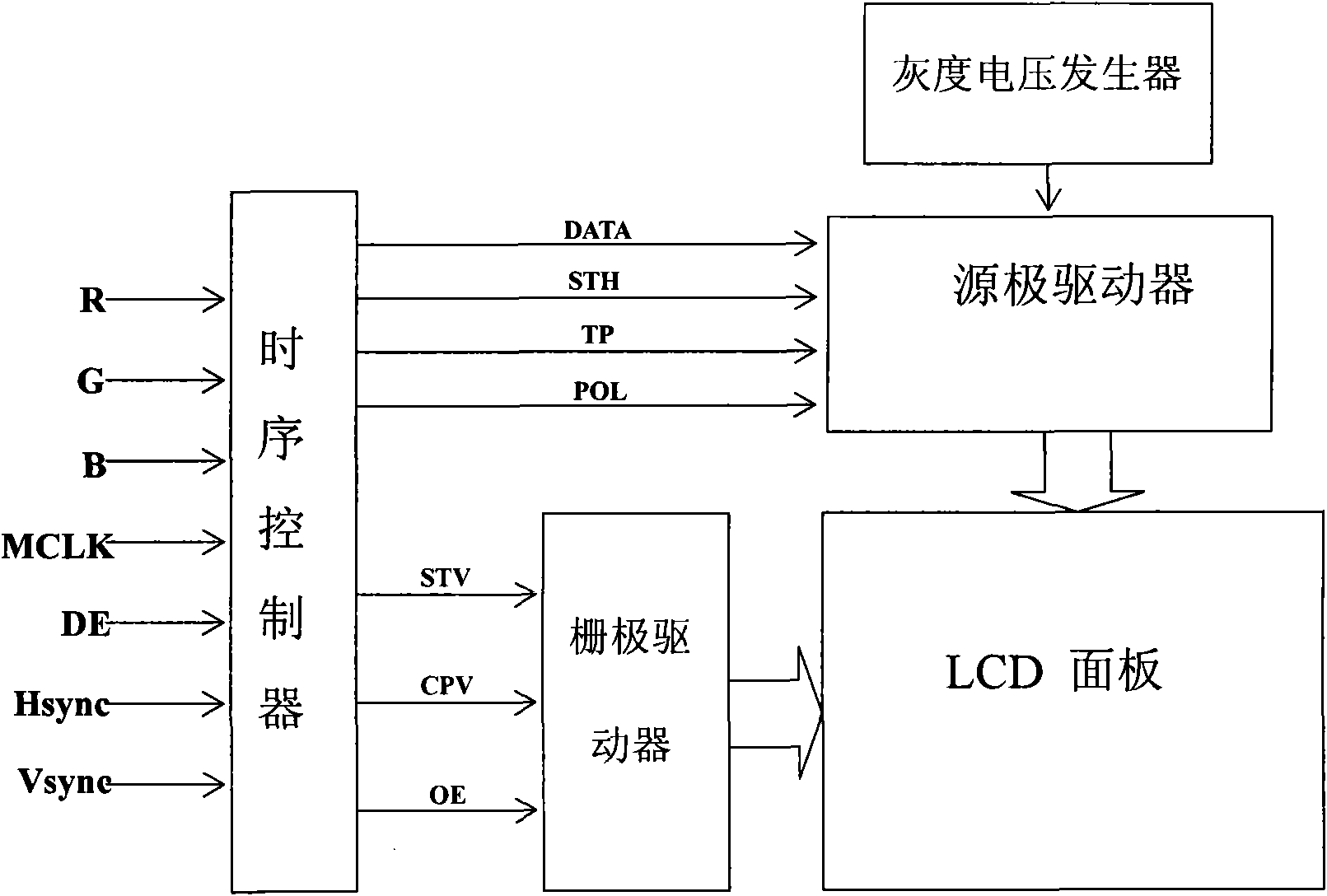

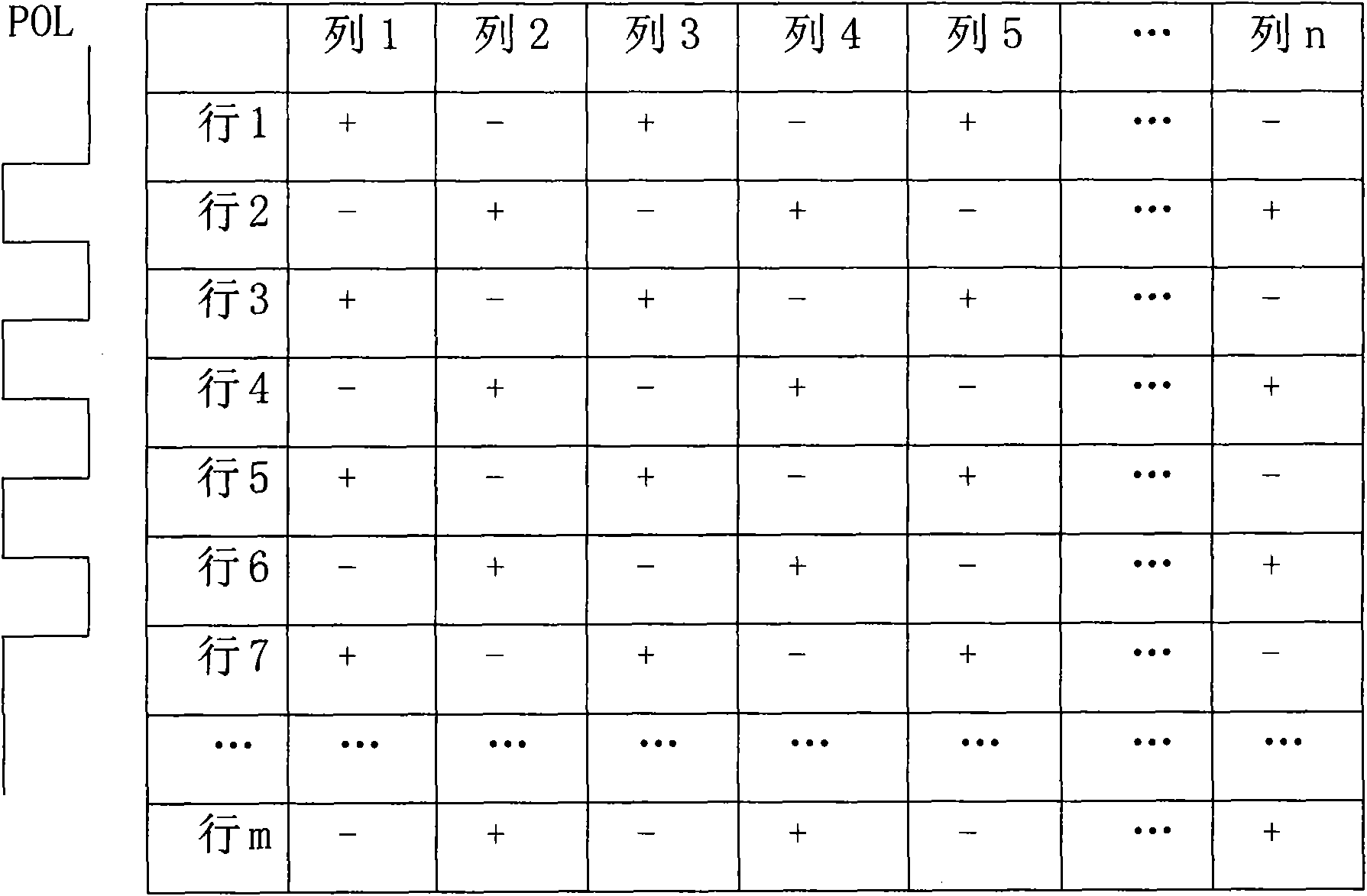

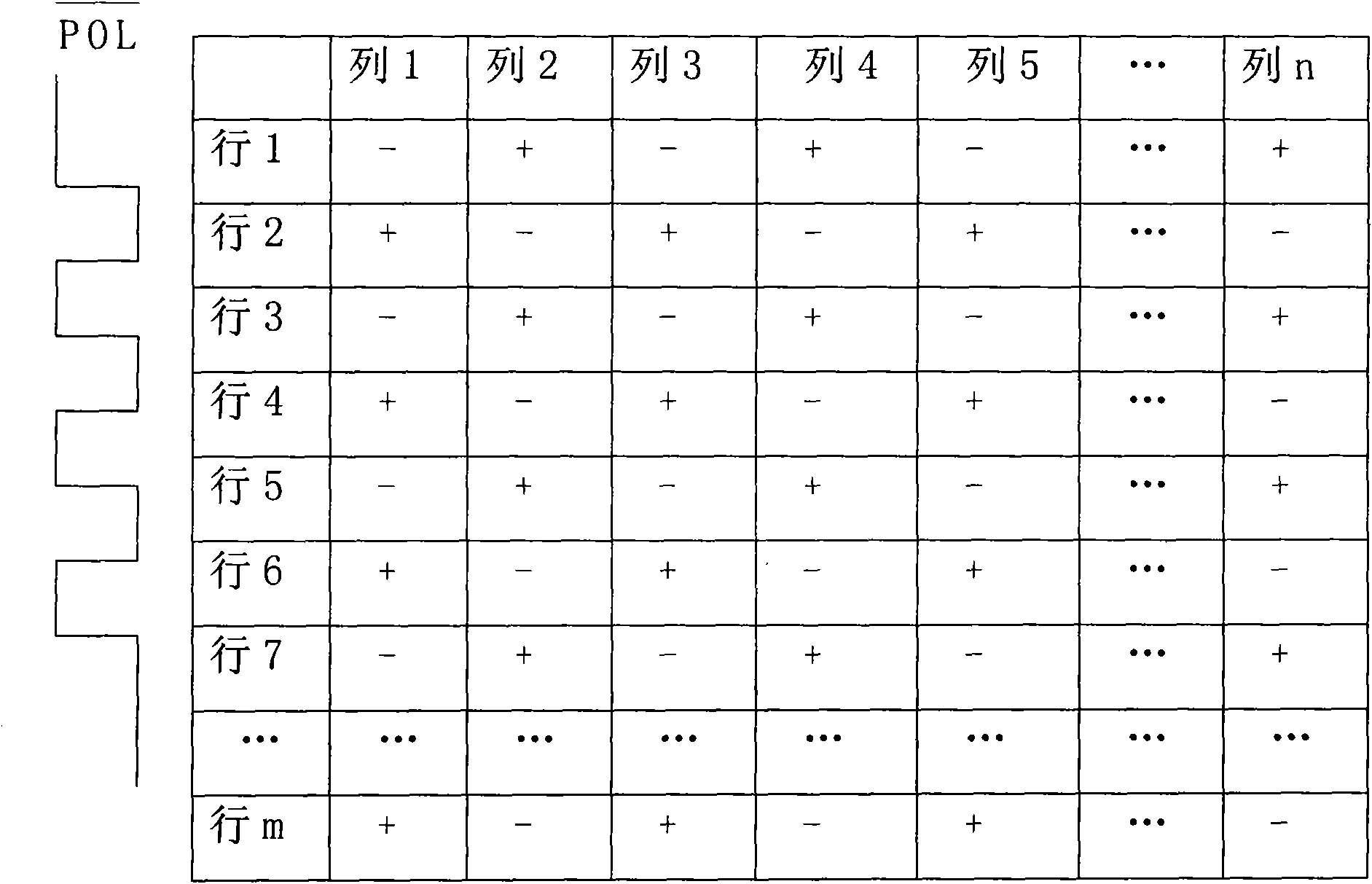

Driving method of liquid crystal display device

InactiveCN101567169ASolve the adhesionSolve crosstalkStatic indicating devicesLiquid-crystal displayControl signal

The invention discloses a driving method of a liquid crystal display device, the liquid crystal display device comprises a liquid crystal display panel and N source electrode drivers driving the liquid crystal display panel, wherein N is an integer and is larger than or equal to 2. The driving method provides each source electrode driver with two polarity control signals so as to ensure opposite voltage polarities of corresponding sub-pixel between adjacent source electrode drivers, wherein the first polarity control signal is a polarity reverse signal of a plus phase or a polarity reverse signal of a minus phase; M polarity reverse signals of plus phase and M polarity reverse signals of minus phase are alternatively provided for all N source electrode drivers in the liquid crystal display device, wherein M is an integer and satisfies the formula: M is larger than or equal to 1 and is less than or equal to (N+1) / 2; the second polarity signal is a determined pin signal of high potential or low potential. The driving method can solve the problems of green attachment and interference, and reduces flickers.

Owner:SHANGHAI SVA LIQUID CRYSTAL DISPLAY

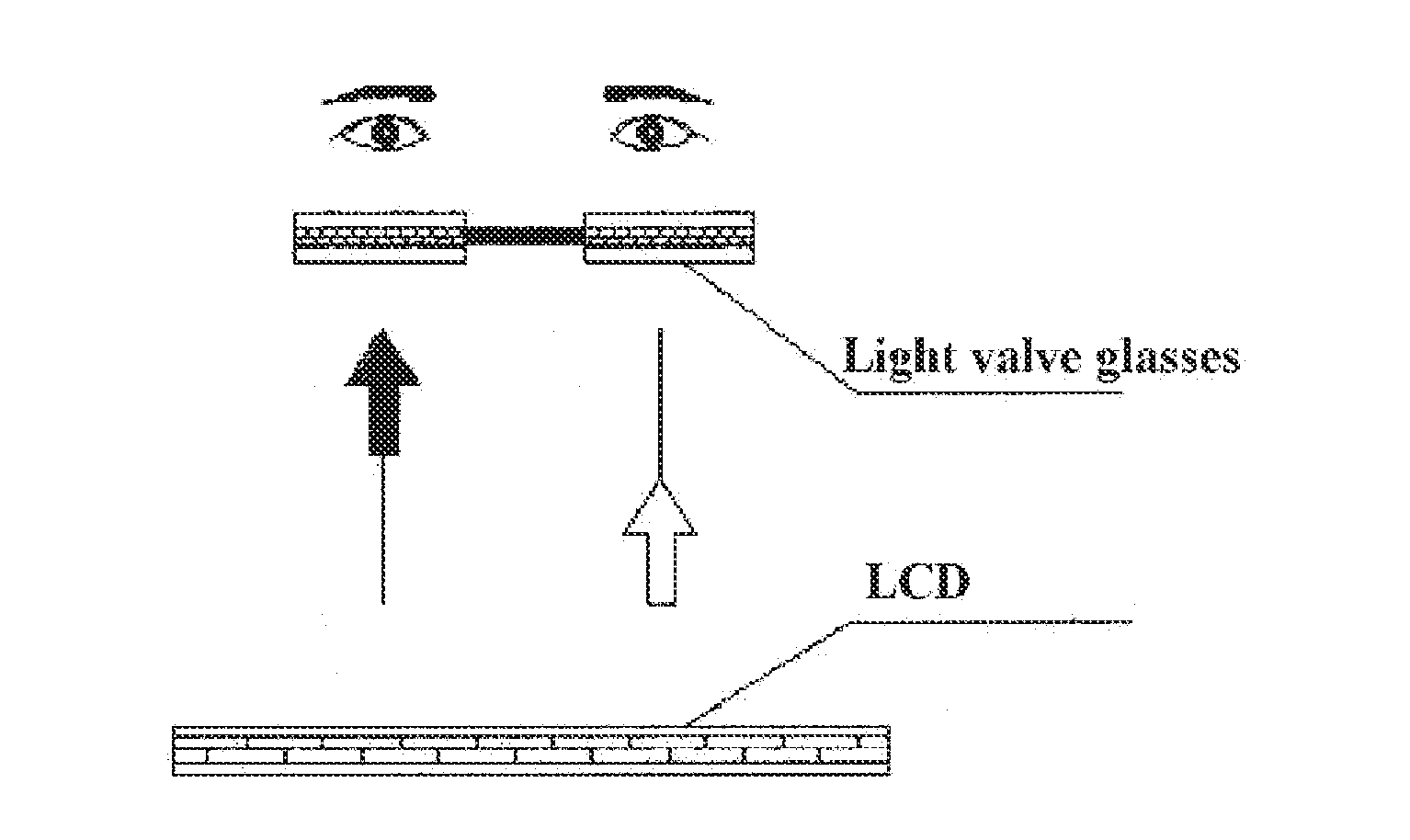

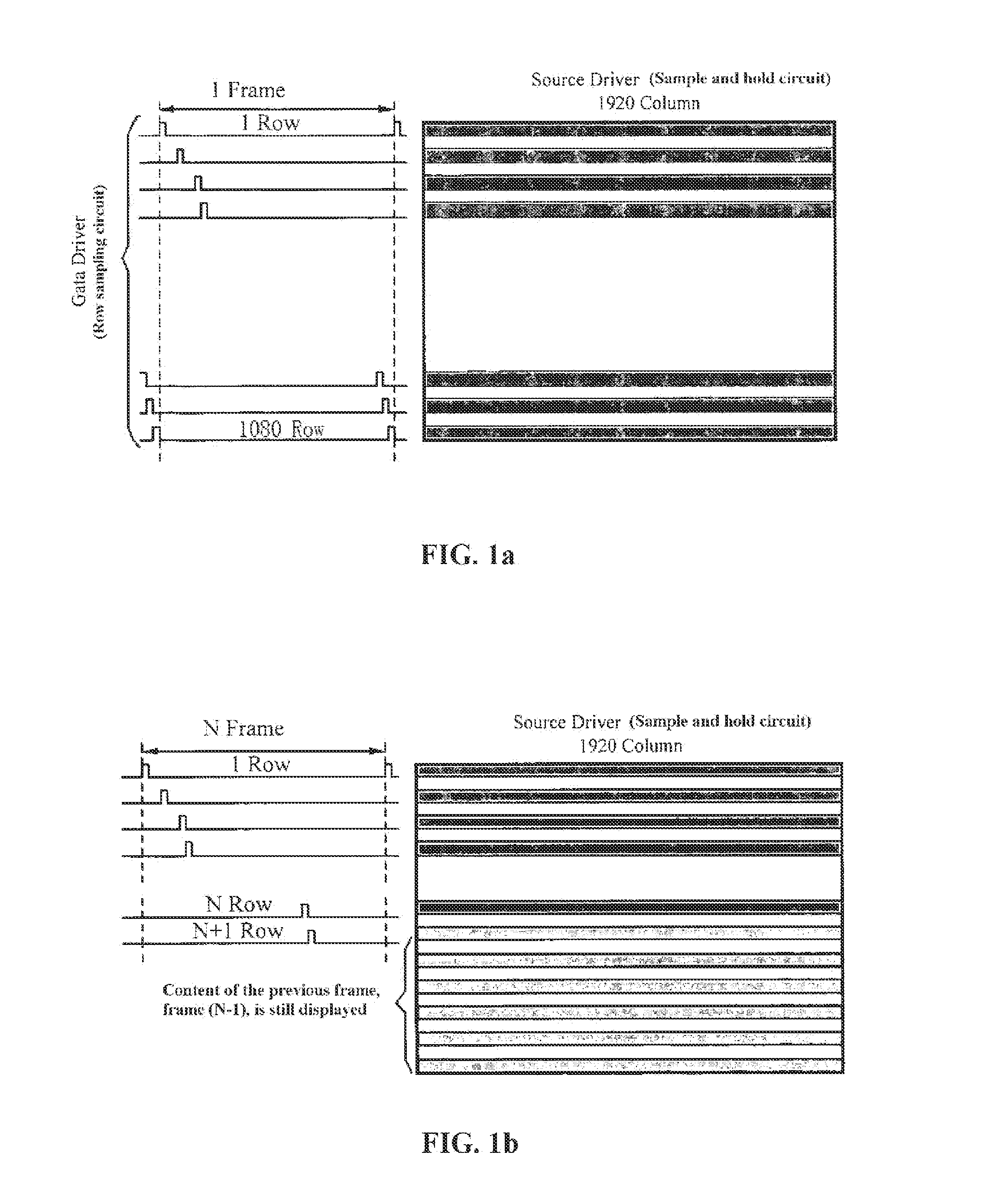

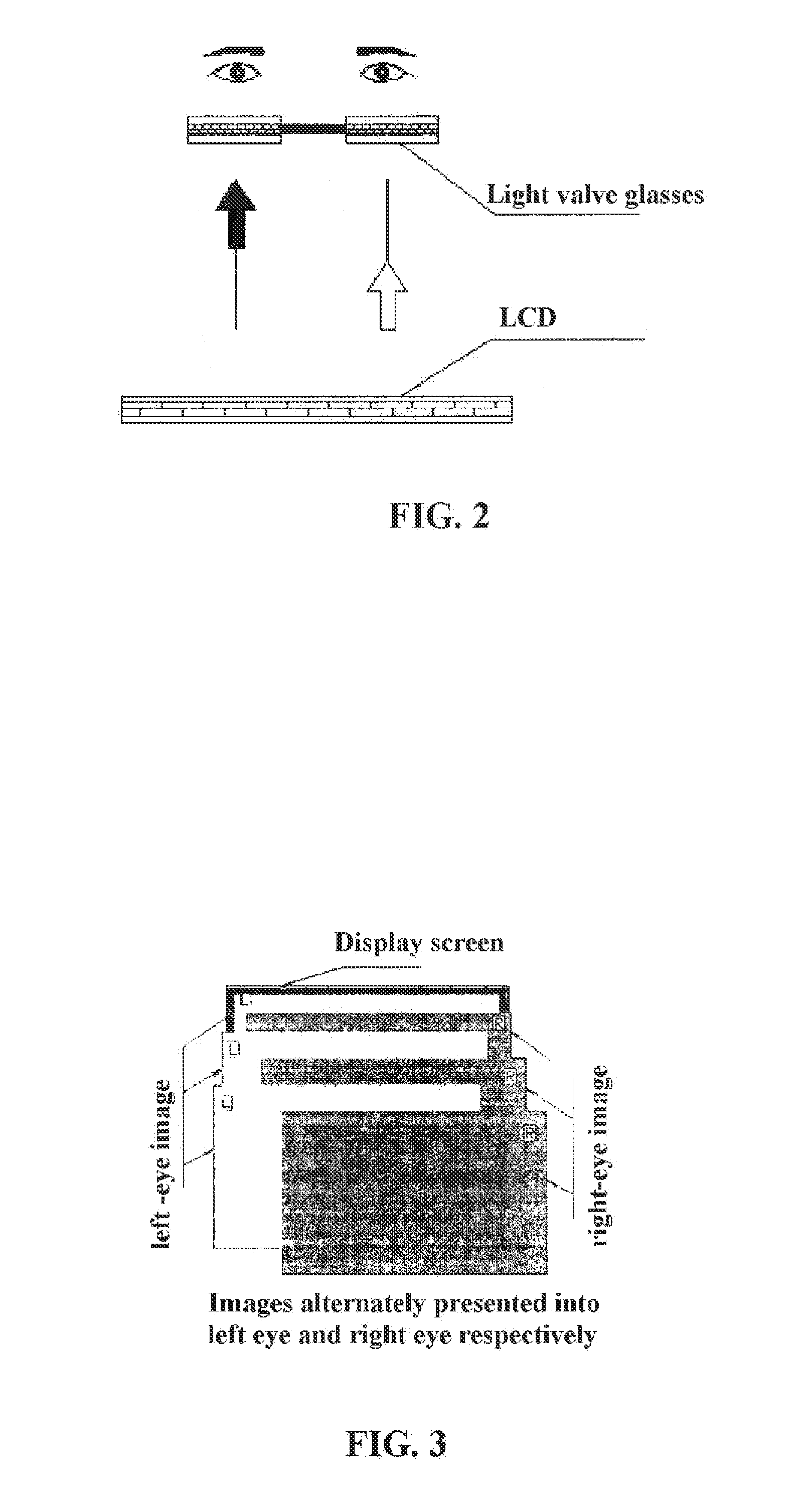

Method, TV set for displaying 3D image and glasses

ActiveUS20120120206A1Degrade perception of 3DReduce power consumptionStatic indicating devicesSteroscopic systems3d imageLight source

A method for displaying 3D image is provided in the present invention. The method includes: 3D image signals, which comprise consecutive one frame of left-eye signal and one frame of right-eye signal, are received; the 3D image signals are processed by frequency multiplication, and n consecutive frames of left-eye signals and n consecutive frames of right-eye signals are obtained, n being the times number of the frequency multiplication and equal to or greater than 2; light-emitting diode (LED) driving signals drive the LED to display the n consecutive frames of left-eye signals and the n consecutive frames of right-eye signals; in the n consecutive frames of left-eye signals, the first frame of left-eye signal corresponds to an LED driving signal which is off, the nth frame of left-eye signal corresponds to an LED driving signal which is on, and in the n consecutive frames of right-eye signals, the first frame of right-eye signal corresponds to an LED driving signal which is off, the nth frame of right-eye signal corresponds to an LED driving signal which is on. The present invention also provides a TV set for displaying 3D image and a pair of glasses for viewing 3D image. By the present invention, the problem of crosstalk between leftimage and rightimage is solved, and backlight sources energy consumption and complete apparatus cost are reduced.

Owner:HISENSE HIVIEW TECH CO LTD +1

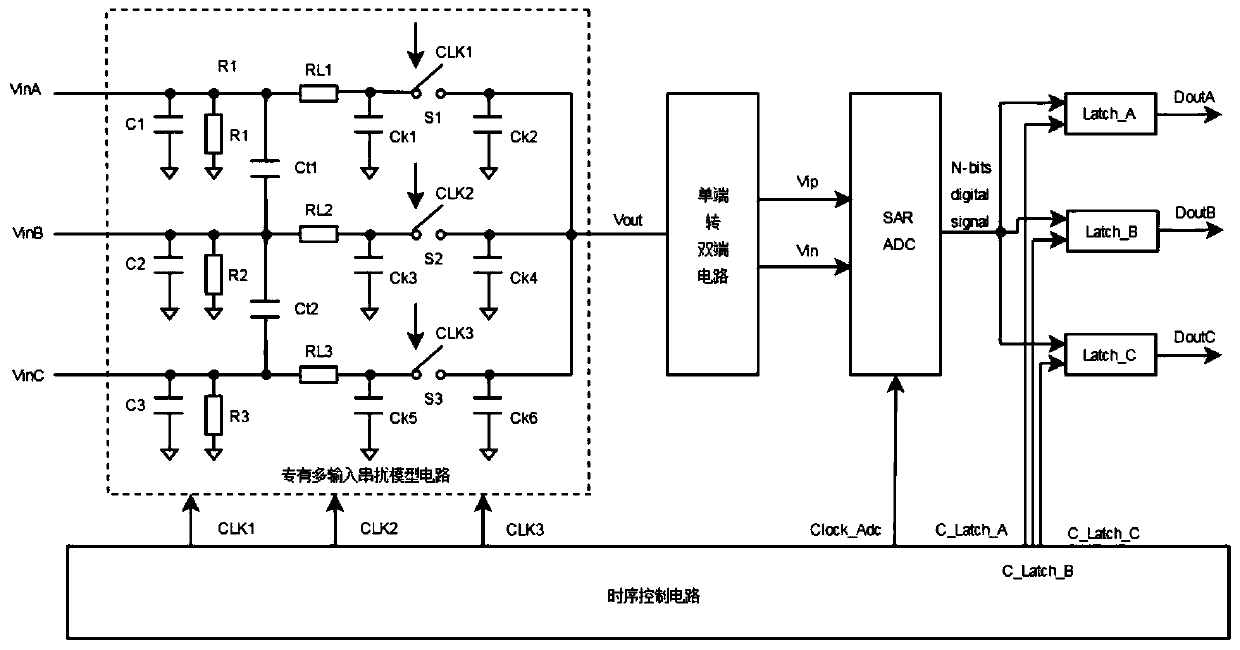

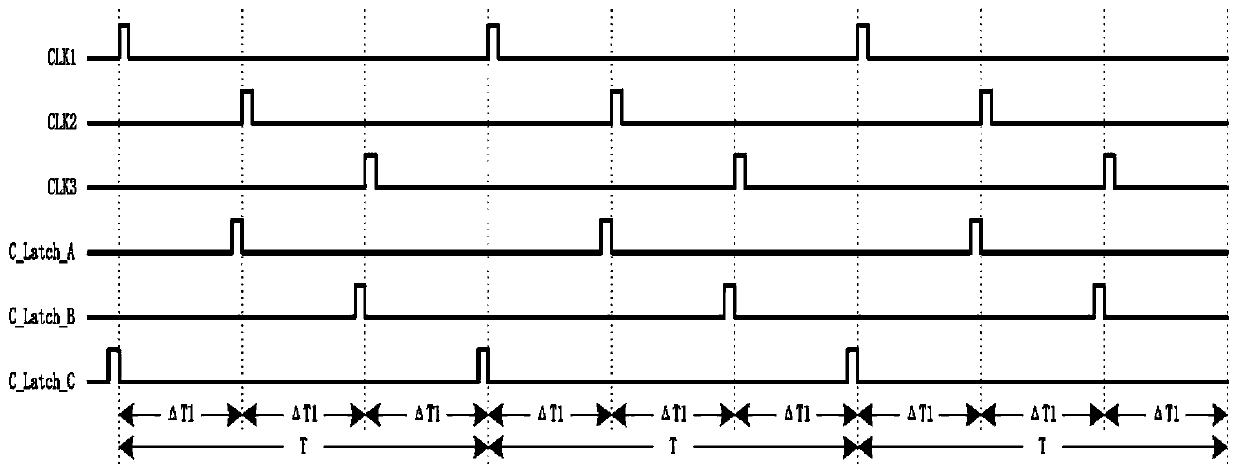

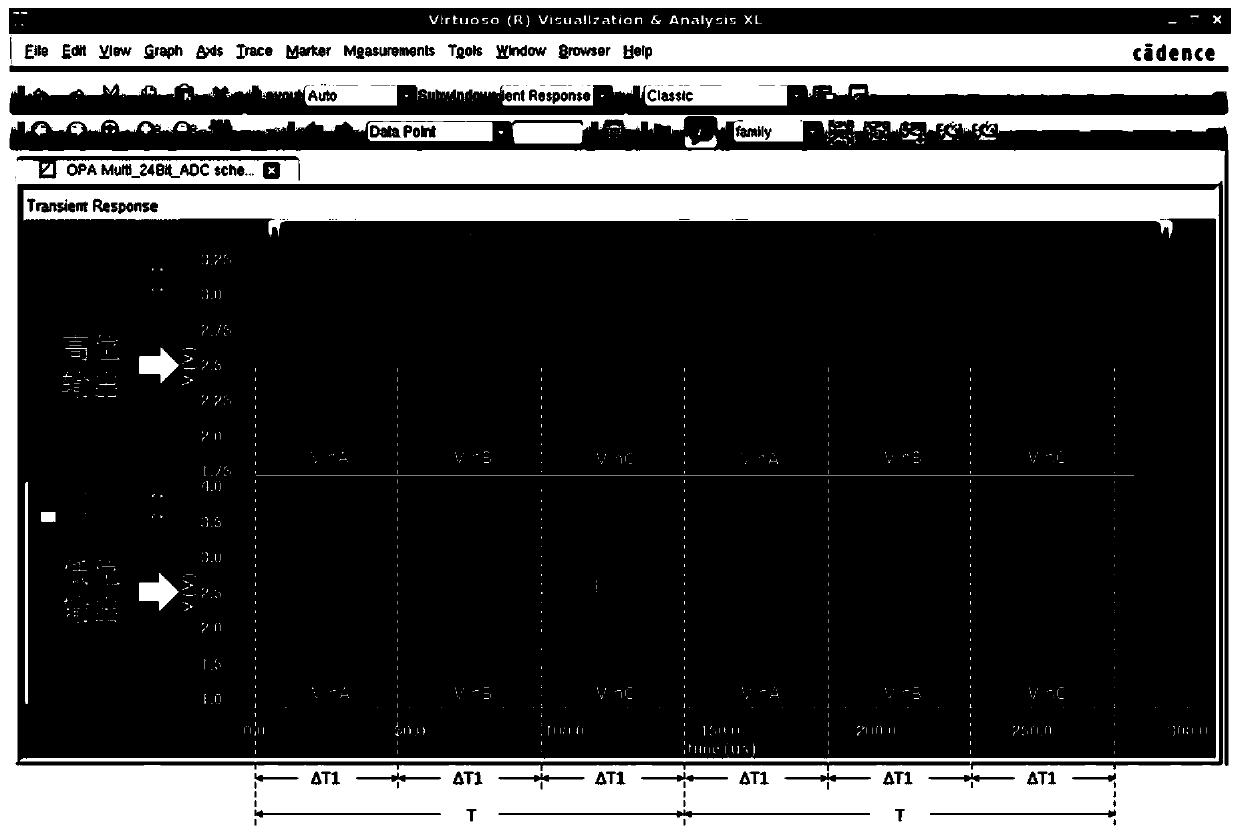

Low input signal crosstalk multipath time division multiplexing SAR ADC circuit system

The invention provides a low input signal crosstalk multipath time division multiplexing an SAR ADC circuit system. The circuit system comprises a special multi-input crosstalk model circuit, a single-ended to double-ended circuit, a successive approximation type analog-to-digital converter SAR ADC, latches Latch _ A, Latch _ B and Latch _ C and a sequential control circuit. By adding the specialmulti-input crosstalk model circuit to the input ends of the SAR ADC, the interference of crosstalk signals between the input ends on sampling signals is suppressed, and the accuracy of SAR ADC outputsignals is improved. According to the invention, the integration level of three-dimensional acceleration is improved, and the area of a chip is reduced; due to the adoption of the special multi-inputcrosstalk model circuit, the problem of crosstalk of multiple paths of sampling signals at the input end is solved; a fully differential structure is adopted to design a multi-channel time division multiplexing SAR ADC, and the interference of input common-mode noise on an SAR ADC circuit is reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

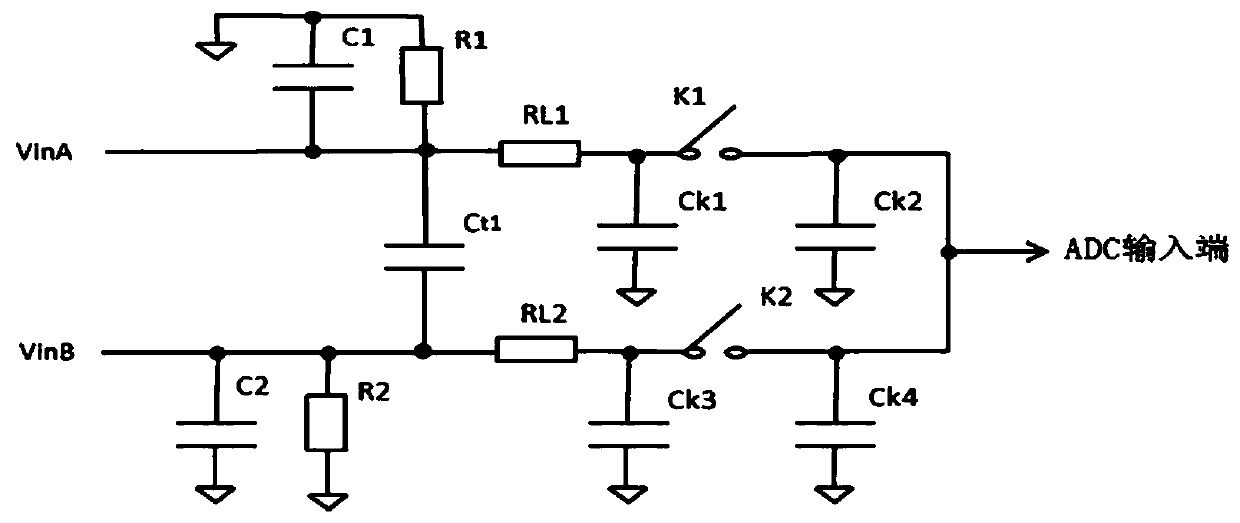

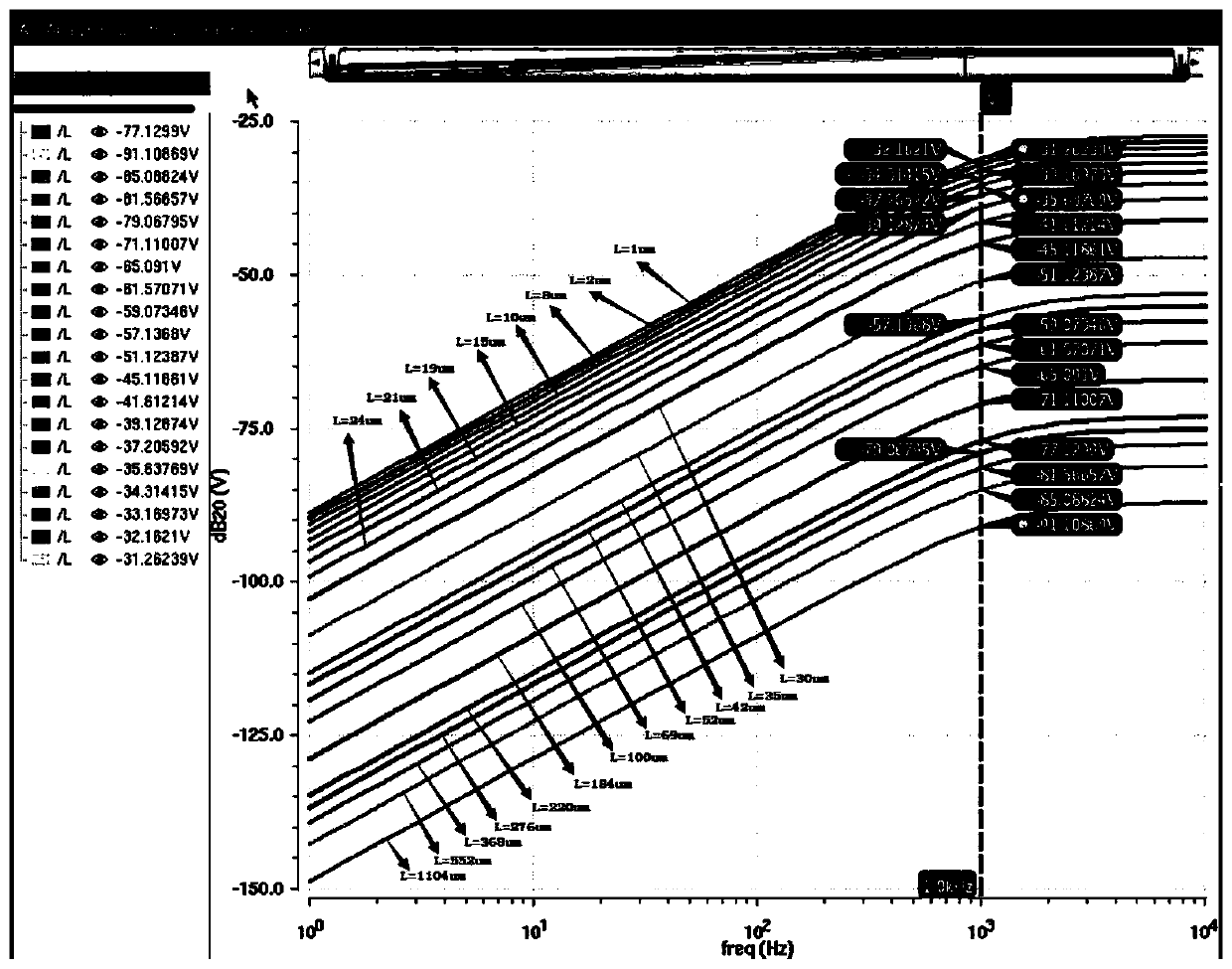

ADC multi-input signal crosstalk model circuit

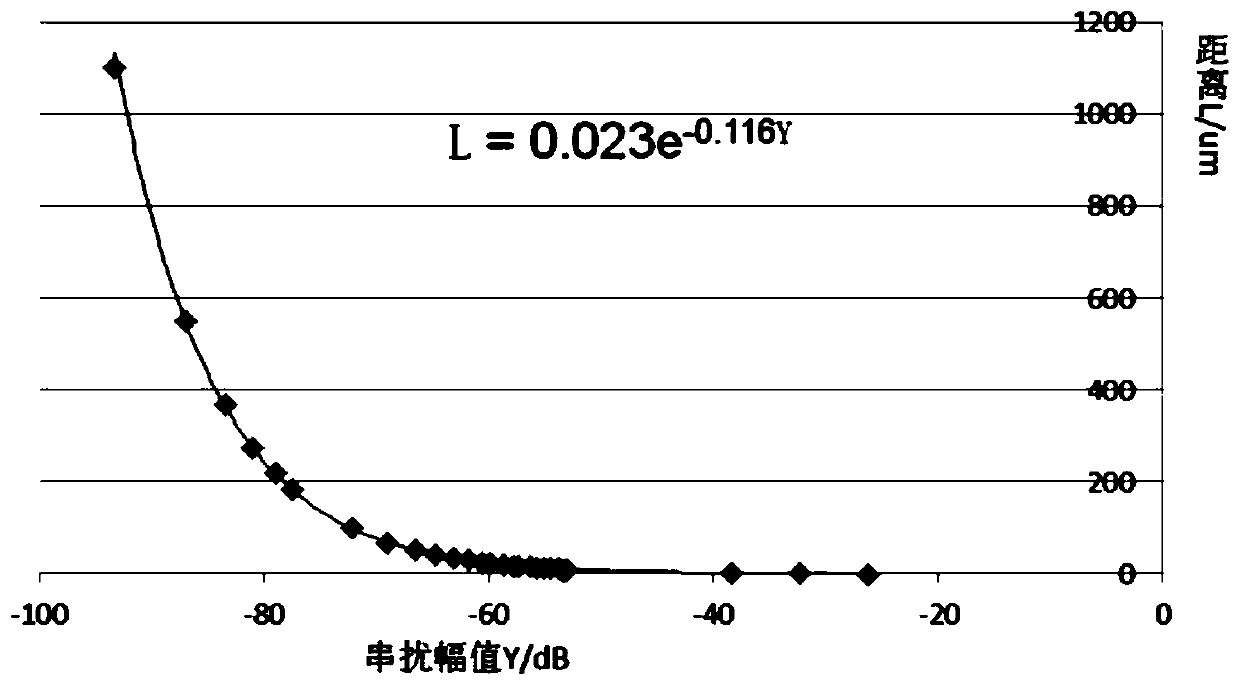

ActiveCN110912557AImprove design efficiencyDistance determinationAnalogue-digital convertersCapacitanceSoftware engineering

The invention provides an ADC multi-input signal crosstalk model circuit. A circuit structure and a connection relationship are provided .Capacitance value and a coupling coefficient of a coupling capacitor are determined by the distance between two input ends. The capacitance value of the coupling capacitor is reduced by changing the distance between the two input ends; the crosstalk amplitude between the signal input ends can be reduced; the distance is calculated between the signal input ends corresponding to the crosstalk amplitude by using the model circuit; and curve fitting is performedon crosstalk amplitude test results corresponding to different distances between the signal input ends to obtain a fitting formula, and the distance between the corresponding signal input ends is calculated by using the obtained fitting formula according to crosstalk amplitude index requirements. Due to the fact that the ADC design is used, the integration degree of the three-dimensional acceleration is improved, and the design area of the chip is reduced. The optimal distance between the signal input ends can be quickly determined according to the crosstalk model circuit fitting graph, and the design efficiency of the circuit is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

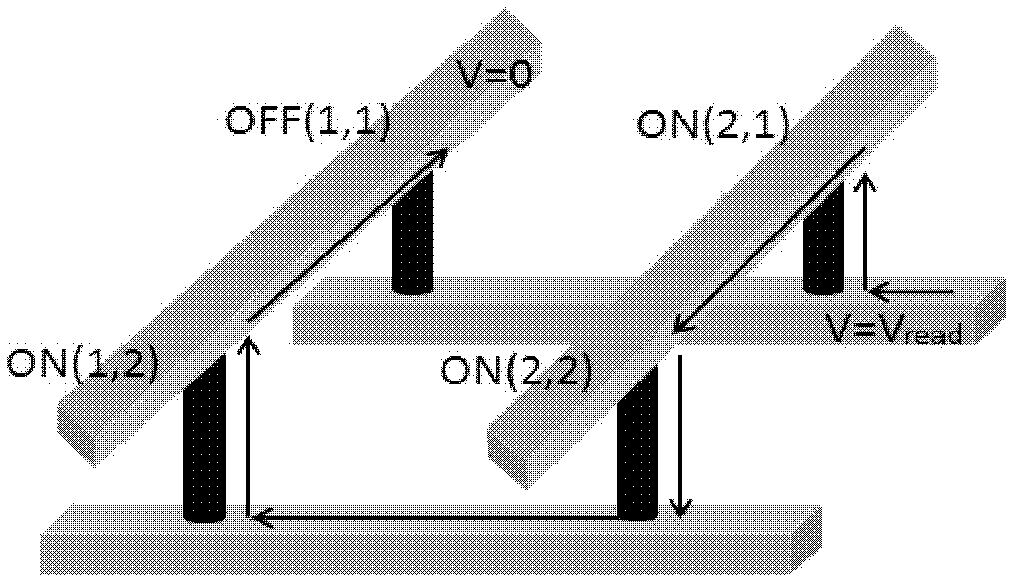

Anti-crosstalk flexible transparent memory array and production method thereof

InactiveCN102593142ADoes not involve high temperatureReduce energy consumptionSolid-state devicesSemiconductor devicesElectronic systemsRandom access memory

The invention discloses an anti-crosstalk flexible transparent memory array and a production method thereof. A transparent selectron serves as a driving tube, repeated erasing and writing of a circuit on memory cells can be achieved through the bidirectional continuity characteristic of the selectron, and a problem of crosstalk is resolved. As the driving tube of the memory array, the selectron resolves the problems of large area of transistors and restriction of unipolar operation of diodes and is adapted to scaling-down process of components. Moreover, the production method of the selectron is simple and cost is saved. The anti-crosstalk flexible transparent memory array uses flexible transparent materials and combines a flexible transparent electronic system, the driving tube and a resistance random access memory. Besides the characteristic of the resistance random access memory, the anti-crosstalk flexible transparent memory array also has the advantages of being flexible, transparent and the like, and particularly resolves the memory crosstalk problem in an integrated array. The produced memory array can be used in electronic paper, flexible transparent display, and other relative electronic systems widely.

Owner:PEKING UNIV

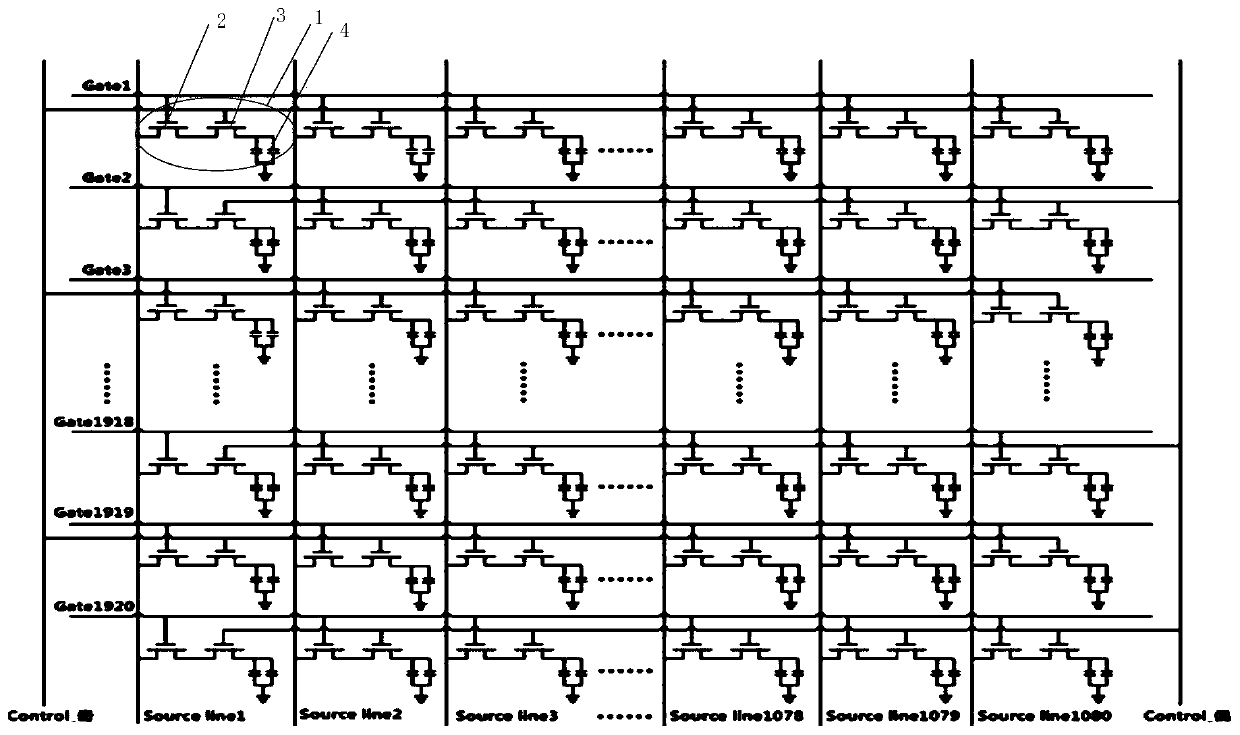

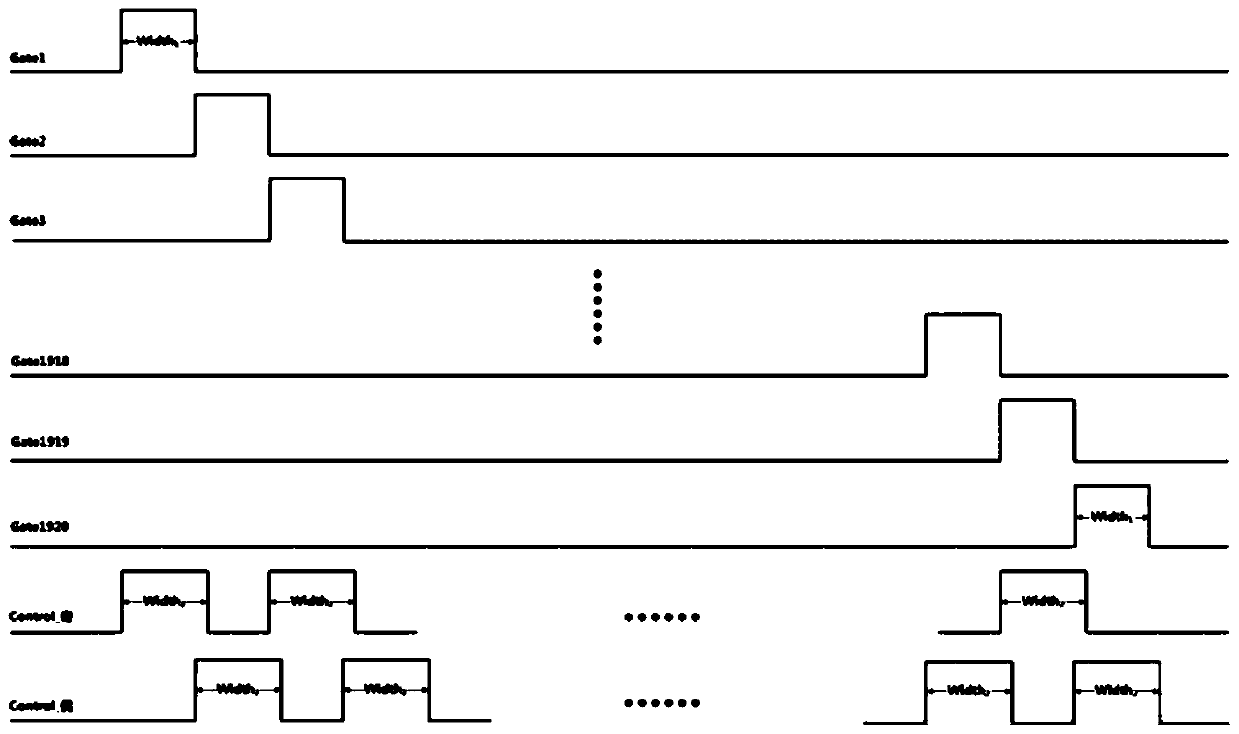

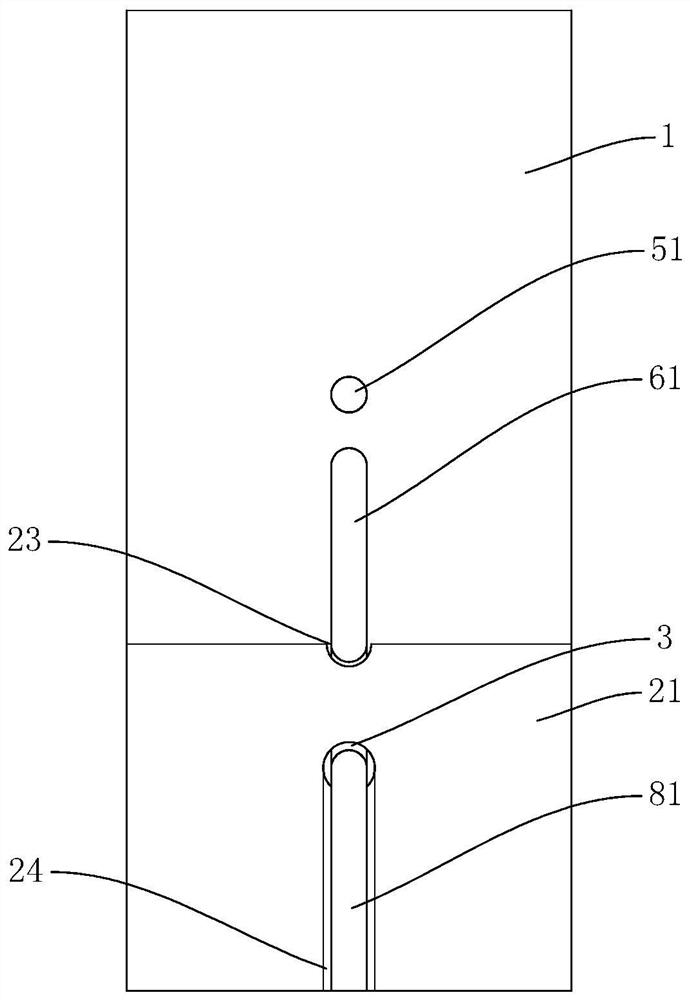

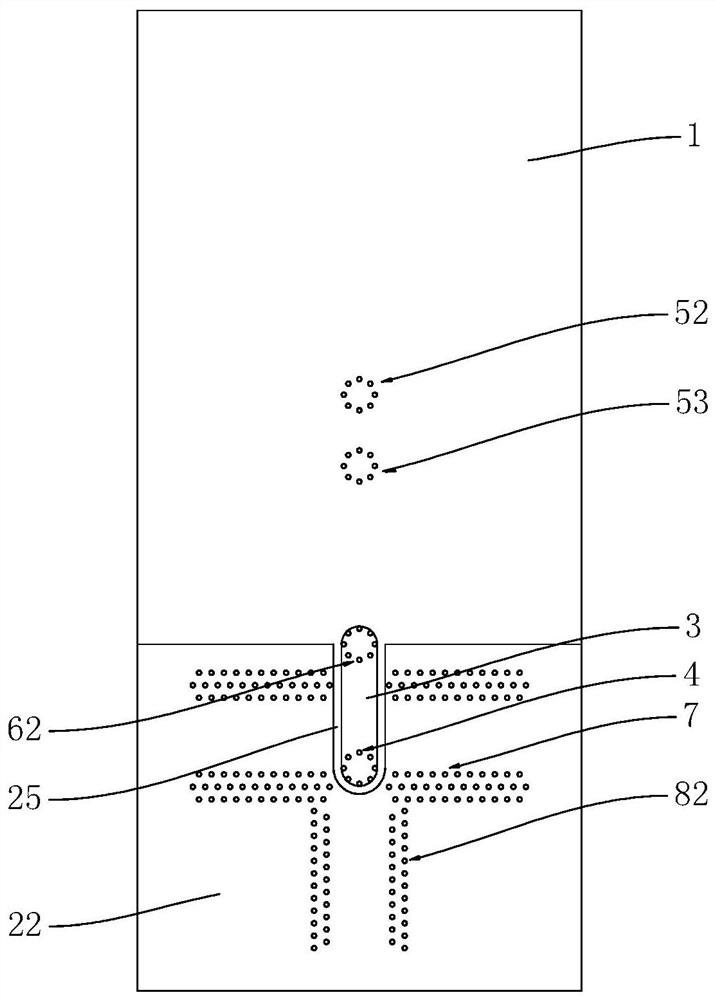

Array substrate, display panel, display device and driving method

ActiveCN109856876AAvoiding the Problem of Being StressedSolve crosstalkStatic indicating devicesNon-linear opticsCapacitanceControl signal

The application discloses an array substrate, a display panel, a display device and a driving method. The array substrate comprises N rows and M columns of pixel units, each pixel unit comprises a first transistor and a second transistor arranged in a serial manner, a source electrode of the first transistor is used for connecting a source electrode driving circuit, a grid electrode of the first transistor is used for connecting a grid electrode driving circuit, a drain electrode of the first transistor is connected with a source electrode of the second transistor, a drain electrode of the second transistor is connected with a pixel capacitor, grid electrodes of the second transistors in the odd number rows are connected with the same first control signal line, grid electrodes of the second transistors in the odd number rows are connected with the same second control signal line, and the first control signal line and the second control signal line are both used for being connected witha display driving IC. According to the above scheme, the problem of crosstalk can be solved.

Owner:BOE TECH GRP CO LTD +1

On-chip antenna based on glass through hole array

ActiveCN112002989AIncrease Radiation GainImprove transmission efficiencyAntenna supports/mountingsRadiating elements structural formsWireless interconnectCoplanar waveguide

The invention discloses an on-chip antenna based on a glass through hole array. The on-chip antenna comprises a glass dielectric substrate, a director, a monopole antenna radiator, a reflecting wall,a top-layer cut-off metal floor, a bottom-layer cut-off metal floor, a bottom-layer metal strip, a connecting glass through hole array and a grounding coplanar waveguide feed structure. According to the on-chip antenna based on the glass through hole array disclosed by the invention, the glass medium with relatively low dielectric constant and dielectric loss is used as an antenna carrier, signalradiation is carried out through the glass through hole array, and the whole antenna has the advantages of large radiation gain, high transmission efficiency and low process cost. The redundant glassthrough hole array is used as a director and a reflecting wall for antenna signal radiation, so that the radiation directivity and the radiation gain of the on-chip antenna are improved. The on-chip antenna is simple in structure and convenient to manufacture, on-chip point-to-point wireless interconnection can be well achieved, and the problems of crosstalk, time delay, parasitic parameters, highpower loss and the like caused by wired connection are effectively solved.

Owner:NINGBO UNIV

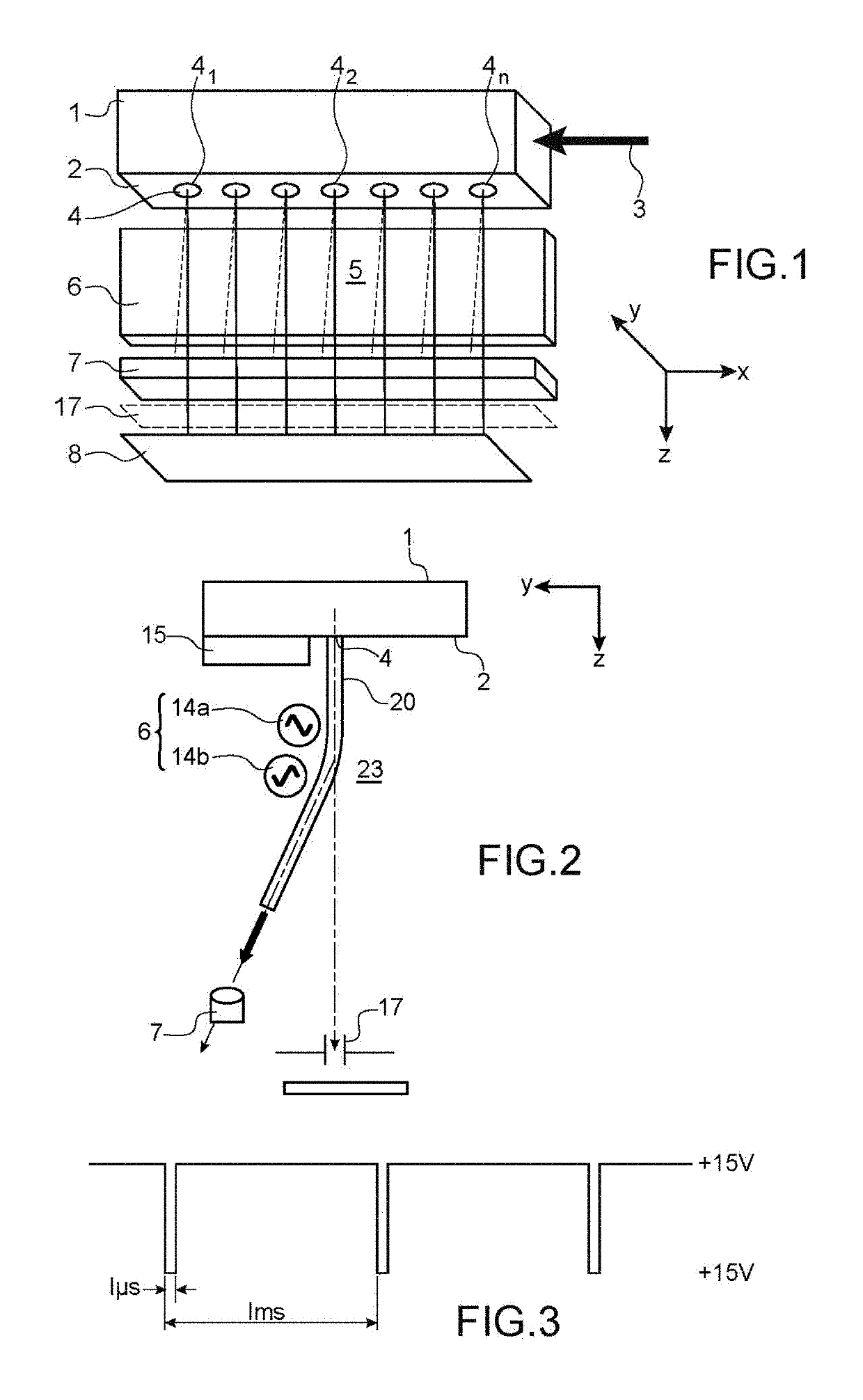

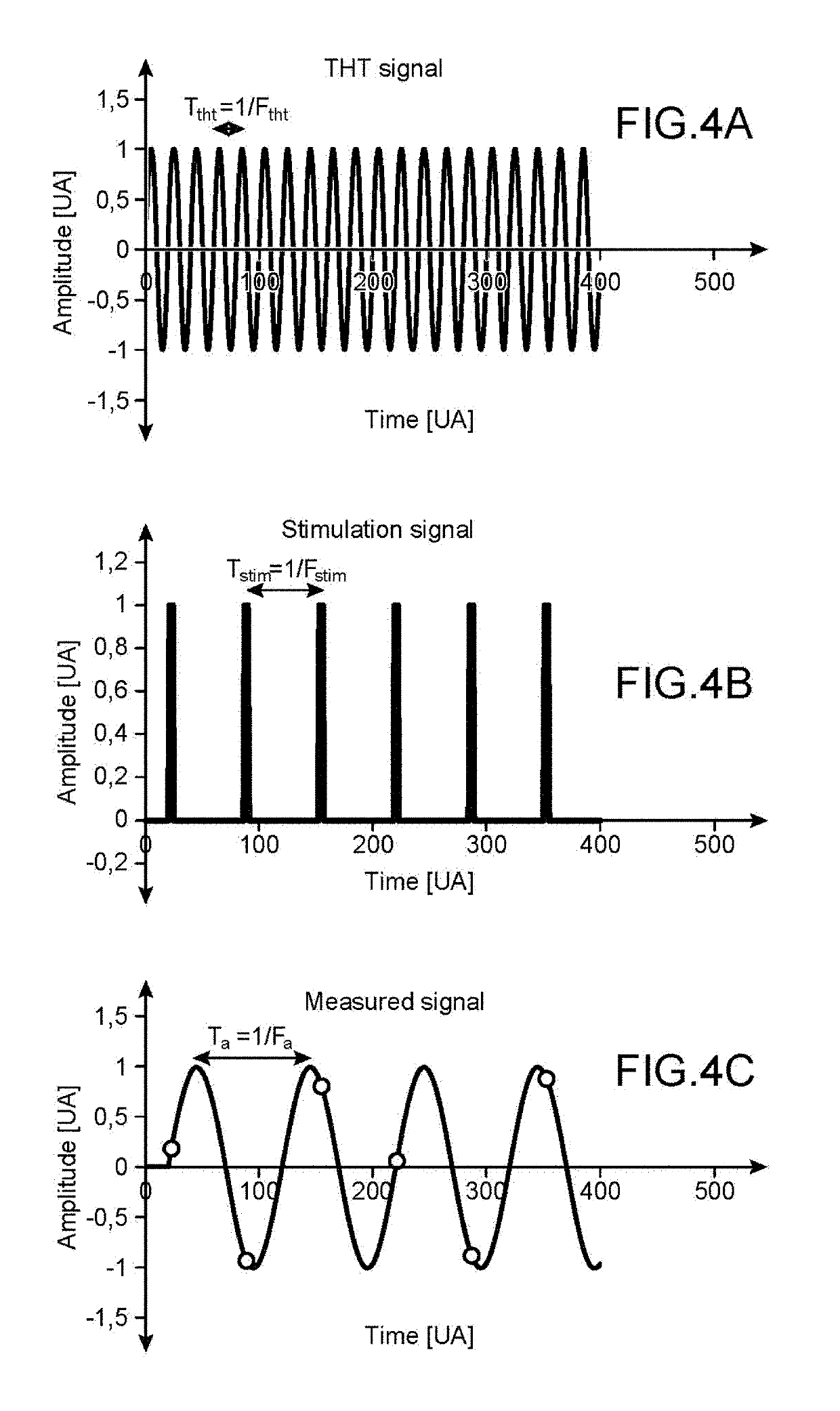

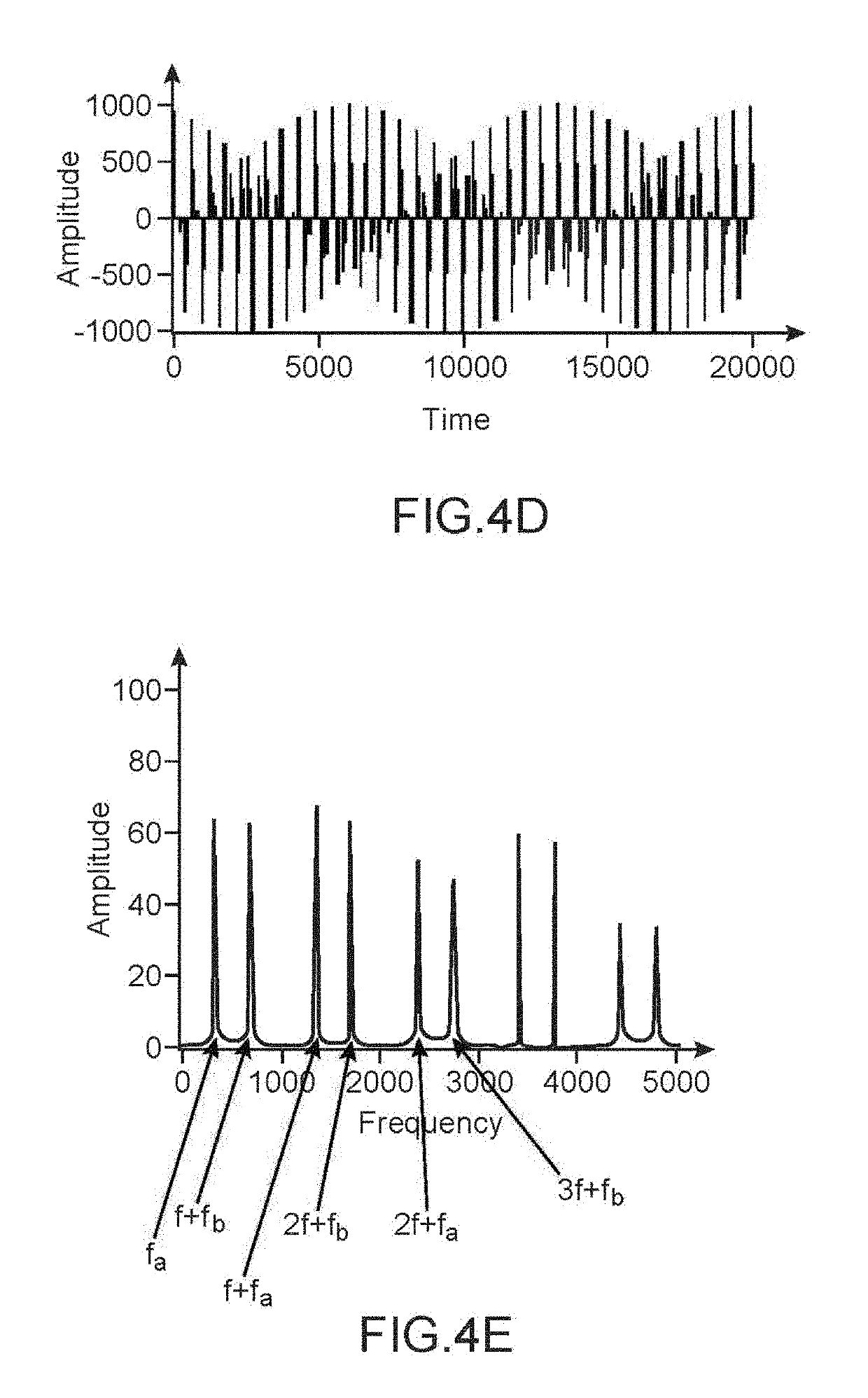

Method and device for detecting the presence of jets

The invention relates to a method for detecting the presence of a jet from a multi-jet print head of an inkjet printer comprising a plurality of nozzles (4), at least one 1st and one 2nd deviation electrode (14a, 14b) for each jet, in which: the inkjet is produced by one of the nozzles, at a frequency fstim1, and is then charged by a voltage VTHT at a frequency fTHT, fTHT not being an integer multiple or sub-multiple of fstim1; a jet charge signal is detected, derived from sampling, at frequency fstim1, of the voltage at frequency fTHT, at least one spectral component of this signal being used to detect the presence of the jet.

Owner:DOVER EURO SARL

Detection circuit and multi-branch recognition device

PendingCN110082587AHigh sensitivitySolve crosstalkMeasurement using digital techniquesAudio power amplifierCurrent voltage

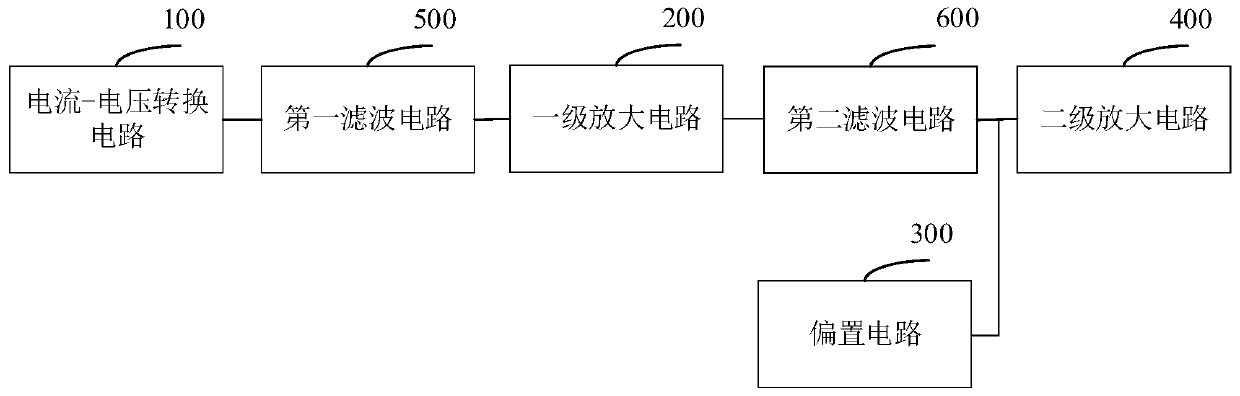

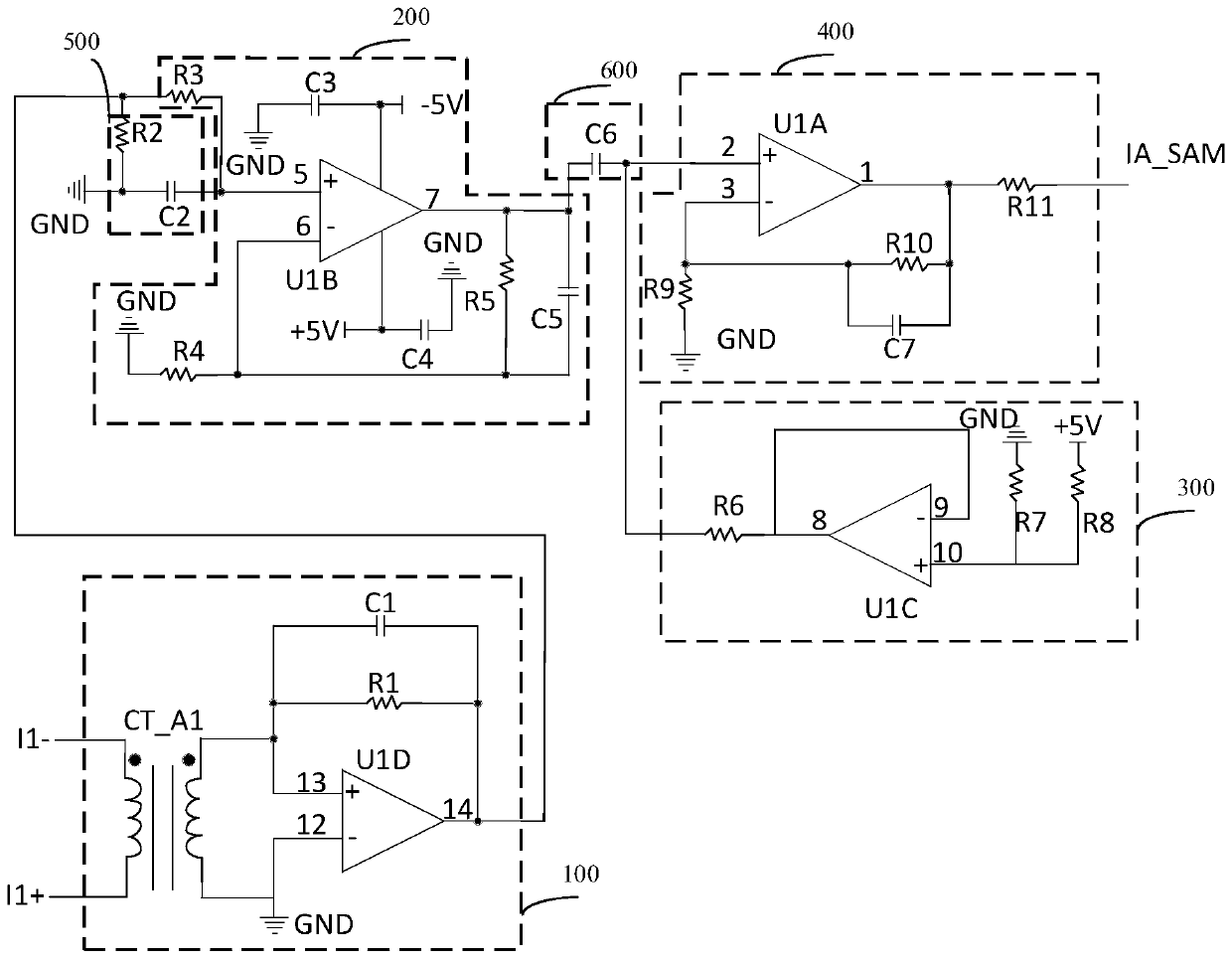

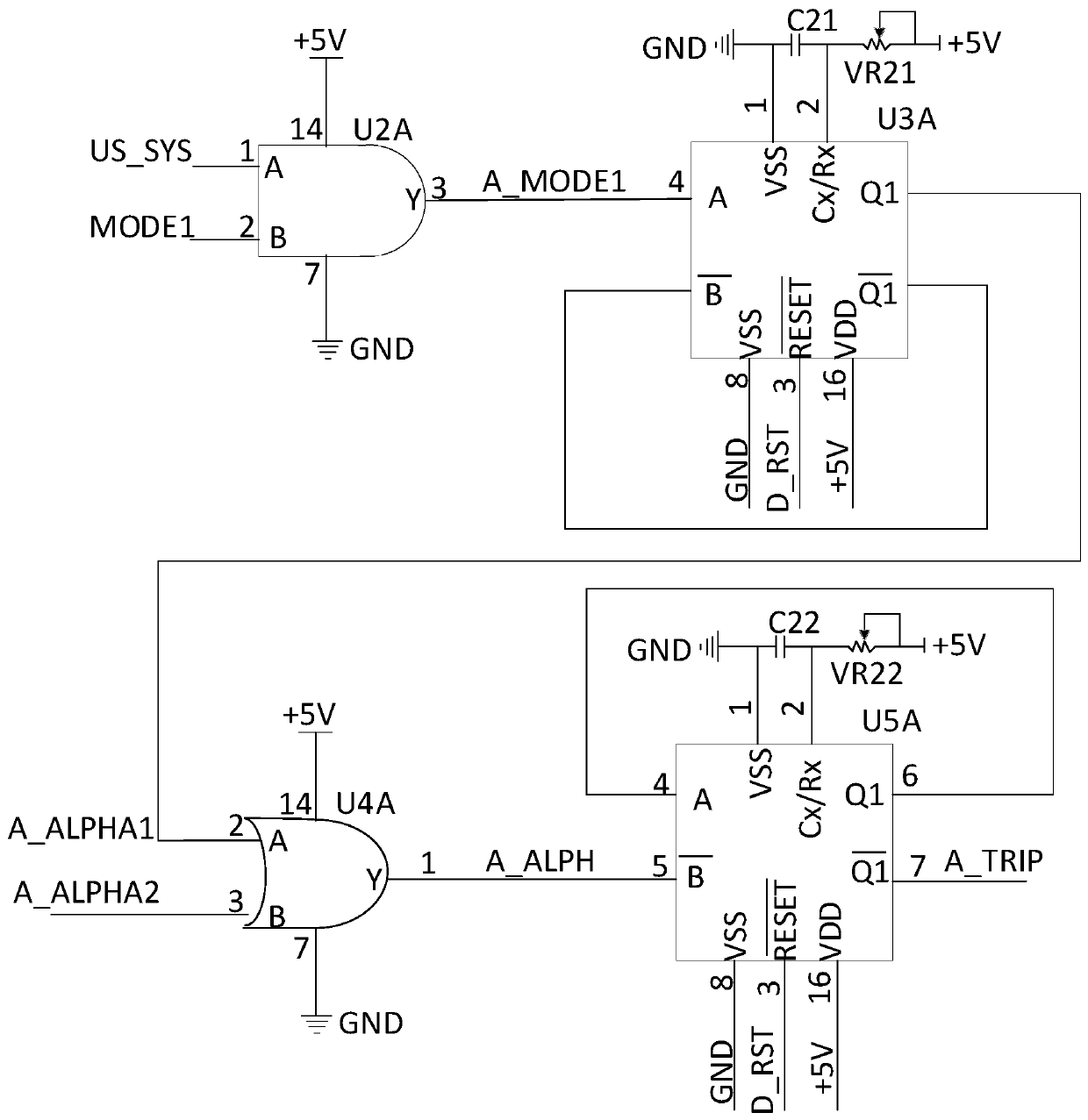

The invention relates to a detection circuit and a multi-branch recognition device. The detection circuit is used for detecting and receiving or transmitting a pulse current signal, and comprises a current-voltage conversion circuit, a primary amplification circuit, a bias circuit and a secondary amplification circuit, wherein the current-voltage conversion circuit comprises a current transformerand a first operational amplifier; the current transformer is used for reducing a first current signal input by the primary side of the current transformer; the first operational amplifier is used forconverting a second current signal output by the secondary side of the current transformer into a first voltage signal; the primary amplification circuit is used for amplifying the first voltage signal into a second voltage signal and outputting the second voltage signal; the bias circuit is used for providing a bias voltage signal; and the secondary amplification circuit is used for amplifying the sum of the second voltage signal and the bias voltage signal into a third voltage signal. Compared with a detection circuit in a traditional identification device, the detection circuit disclosed by the invention is higher in sensitivity and solves the problem of information crosstalk during recognition.

Owner:SHENZHEN POWER SUPPLY BUREAU

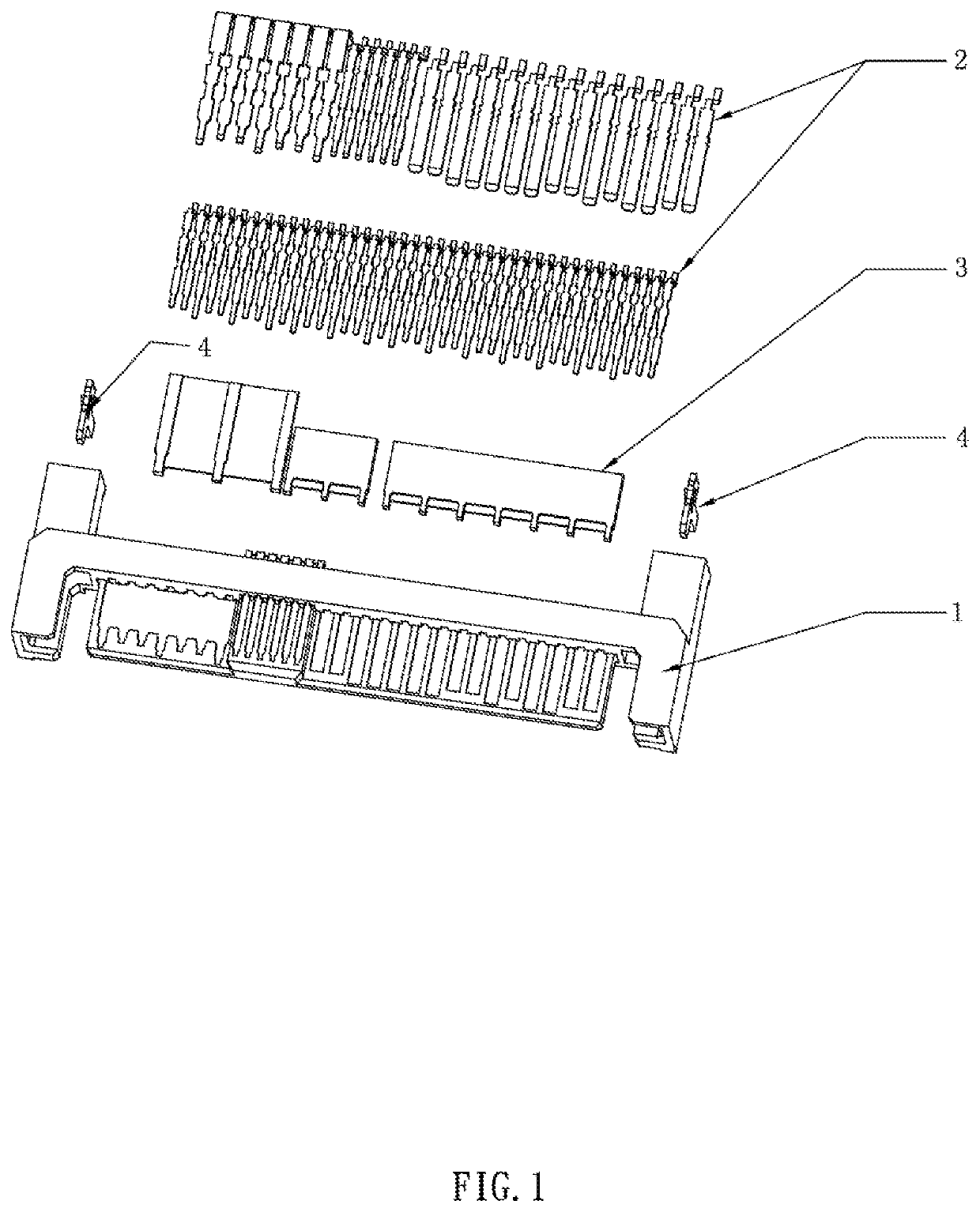

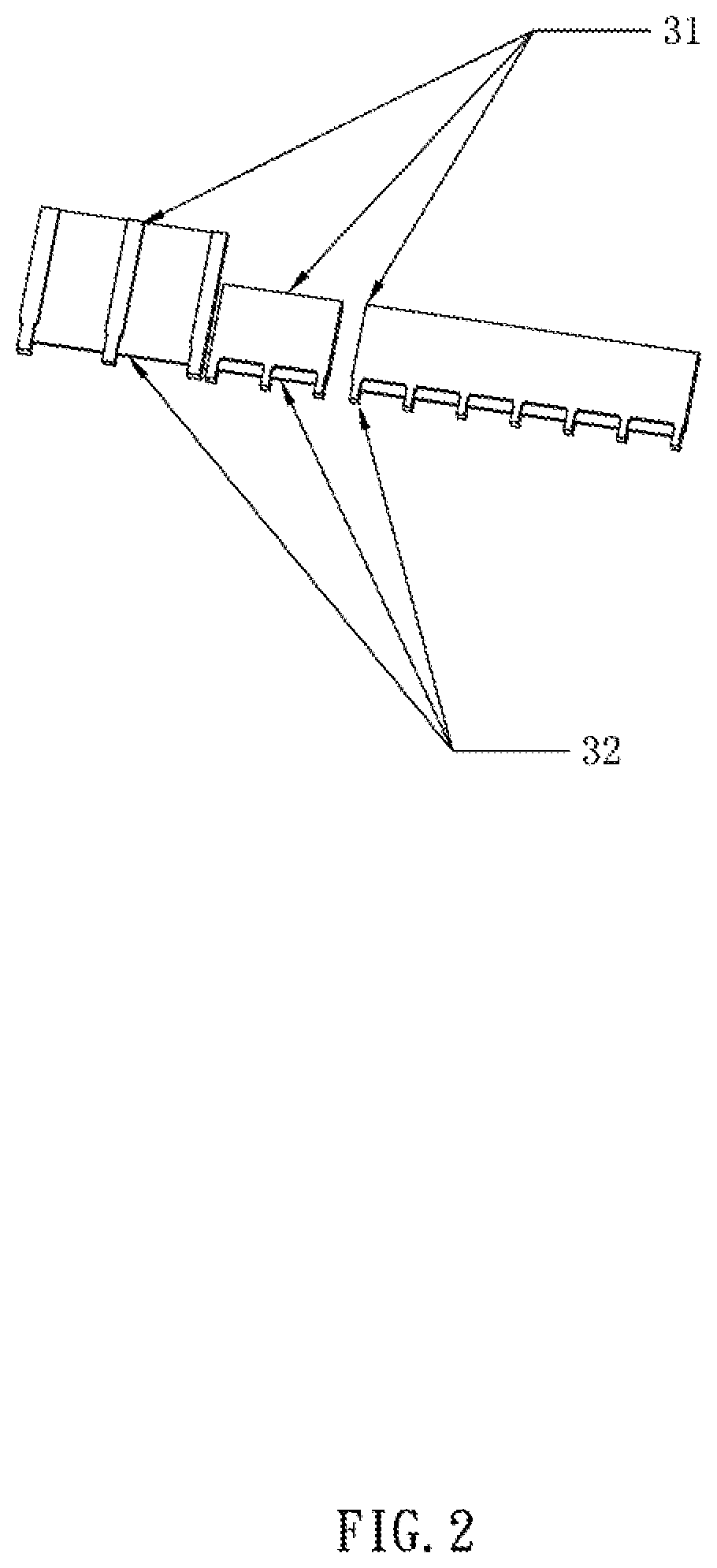

Pcie/sas connector structure

InactiveUS20200028289A1Reduce warpageSolve crosstalkCoupling device detailsPlastic materialsStructural engineering

A PCIe / SAS connector structure related to the connector field is provided, including a body member, a terminal assembly, a cover member, and a fixing plate. The body member includes a terminal groove and is formed of a plastic material. The terminal assembly includes a signal terminal and a power terminal, and is inserted in the terminal groove in the body member. The cover member includes an electrically conductive plastic member and a metal cover plate, and structurally formed in a plate shape. When the terminal assembly is inserted in the body member, the cover member is embedded in the body member and disposed at an inner lateral of the terminal assembly. The electrically conductive plastic member is divided into at least two sections. The metal cover plate is embedded in the electrically conductive plastic member. With such configuration, a plurality of advantageous effects are achieved.

Owner:AMPHENOL EAST ASIA ELECTRONICS TECH SHENZHEN

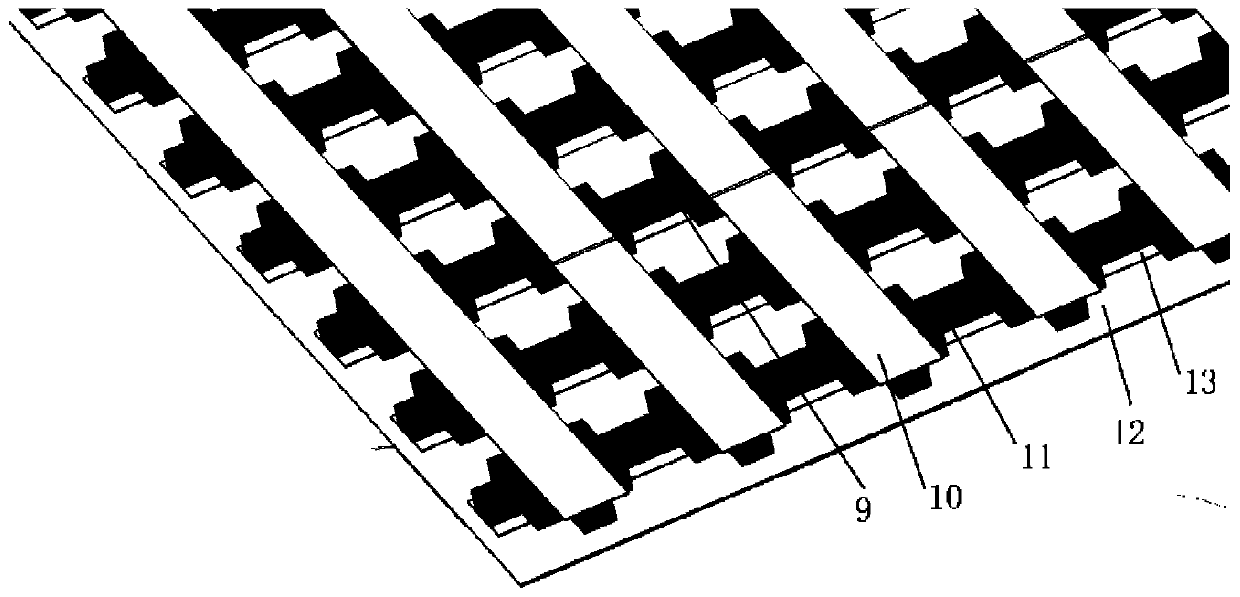

Flexible pressure sensing array prepared by utilizing laser cutting manner

InactiveCN109916539AReduce the cross-sectional areaIncrease resistanceForce measurementLaser beam welding apparatusTectorial membraneLaser resection

The invention discloses a flexible pressure sensing array prepared by utilizing a laser cutting manner. The flexible sensing array is composed of a plurality of sensing units connected in parallel, each of the sensing units is a five-layer superimposed structure, and the five-layer superimposed structure separately includes a substrate film, a column electrode, a laser-cut hollow-out piezoresistive film, a row electrode and a protective film from bottom to top, the column electrode is printed on the substrate film, an electrode of the row electrode is printed on the protective film, the laser-cut hollow-out piezoresistive film is sandwiched between the substrate film printed with the column electrode and the protective film printed with the row electrode, and the substrate film and the protective film are bonded together by glue; and in order to reduce crosstalk between the sensing units, a part of the piezoresistive film between the sensing units utilizes laser resection, and a part of connection is remained between the sensing units to keep a relative position and an overall shape unchanged. The flexible pressure sensing array enables the crosstalk to be reduced without increasing assembly complexity, solves the conflict of the crosstalk and the assembly complexity, and can be simultaneously applied to real-time graphical pressure distribution display.

Owner:EAST CHINA NORMAL UNIV

Storage electrode connecting framework of liquid crystal display

ActiveCN102253543ASolve crosstalkSolve problems such as flickeringNon-linear opticsLiquid-crystal displayImage signal

The invention discloses a storage electrode connecting framework of a liquid crystal display. The storage electrode connecting framework comprises a plurality of scanning lines formed in a horizontal direction, a plurality of data lines formed in a vertical direction, pixel electrodes which are formed in pixel regions defined by the crossing of the scanning lines and the data lines and are used for receiving image signals through the data lines, a storage circuit which comprises a storage electrode line and a storage electrode for connecting the storage electrode line, and a storage circuit connecting line slantly connected with an adjacent storage electrode, wherein the data lines are crossed with the scanning lines and insulated from the scanning lines. The storage circuit is slantly connected with the adjacent storage electrode, the crosstalk or flash problem caused by a condition that the signal easily has a delay phenomenon in a picture central part is solved, and the stripe visual problem can be improved by controlling a connecting distance in a slant direction.

Owner:NANJING CEC PANDA LCD TECH

Laser radar and intelligent sensing device

PendingCN110753855AAchieve occlusionRealize the shielding effectElectromagnetic wave reradiationEngineeringRadar detection

The embodiment of the present application relates to the field of laser detection technology, and discloses a laser radar and an intelligent sensing device, including: a body and a protective cover; the body is located in the protective cover and rotates relative to the protective cover; a laser emitting unit and a laser receiving unit are adjacently arranged on one side of the body, and an optical isolating plate is disposed between the laser emitting unit and the laser receiving unit. One end of the optical isolating plate is disposed on the body, and the other end faces the protective coverand extends and shifts to the side of the laser emitting unit or the laser receiving unit, and rotates relative to the protective cover. In the above manner, the embodiment of the present applicationachieves shielding and blocking of interfering laser signals, well solves the problem of crosstalk between signals due to laser signal scattering and reflection of the protective cover, and improvesthe laser radar detection accuracy.

Owner:SUTENG INNOVATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com