Flexible pressure sensing array prepared by utilizing laser cutting manner

A laser cutting and sensing array technology, applied in the field of flexible sensors, can solve the problems of large crosstalk of flexible pressure sensing arrays, easy mutual interference of pressure signals, low accuracy of pressure signals, etc., so as to solve the conflict between crosstalk and assembly complexity , Simple assembly, the effect of increasing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

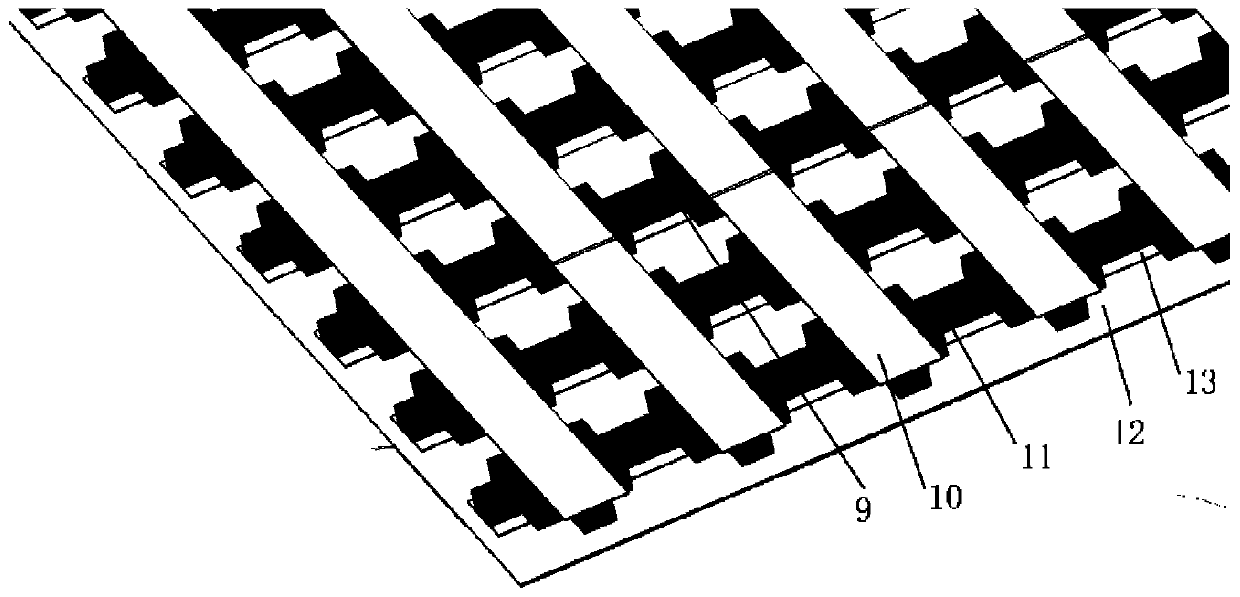

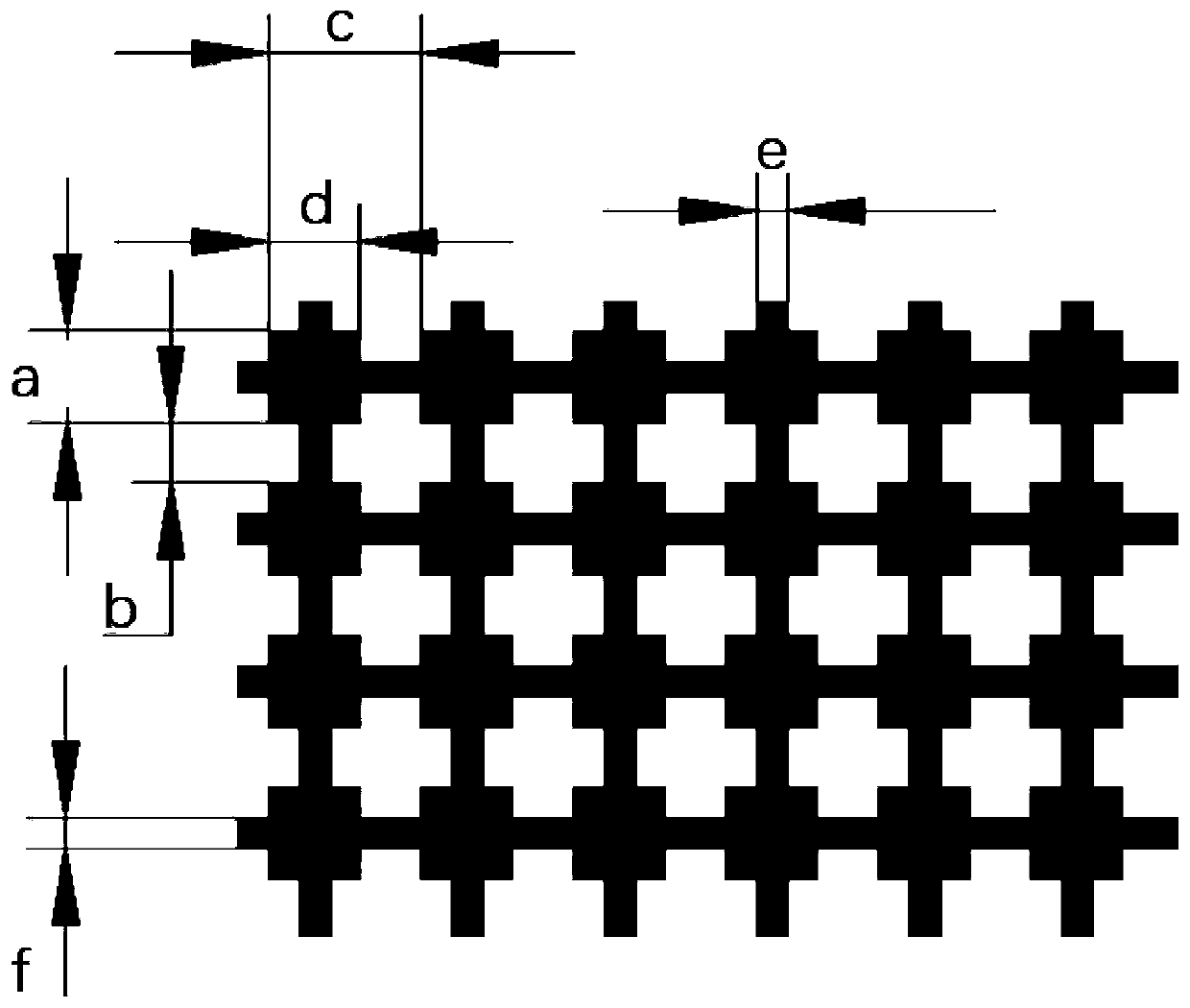

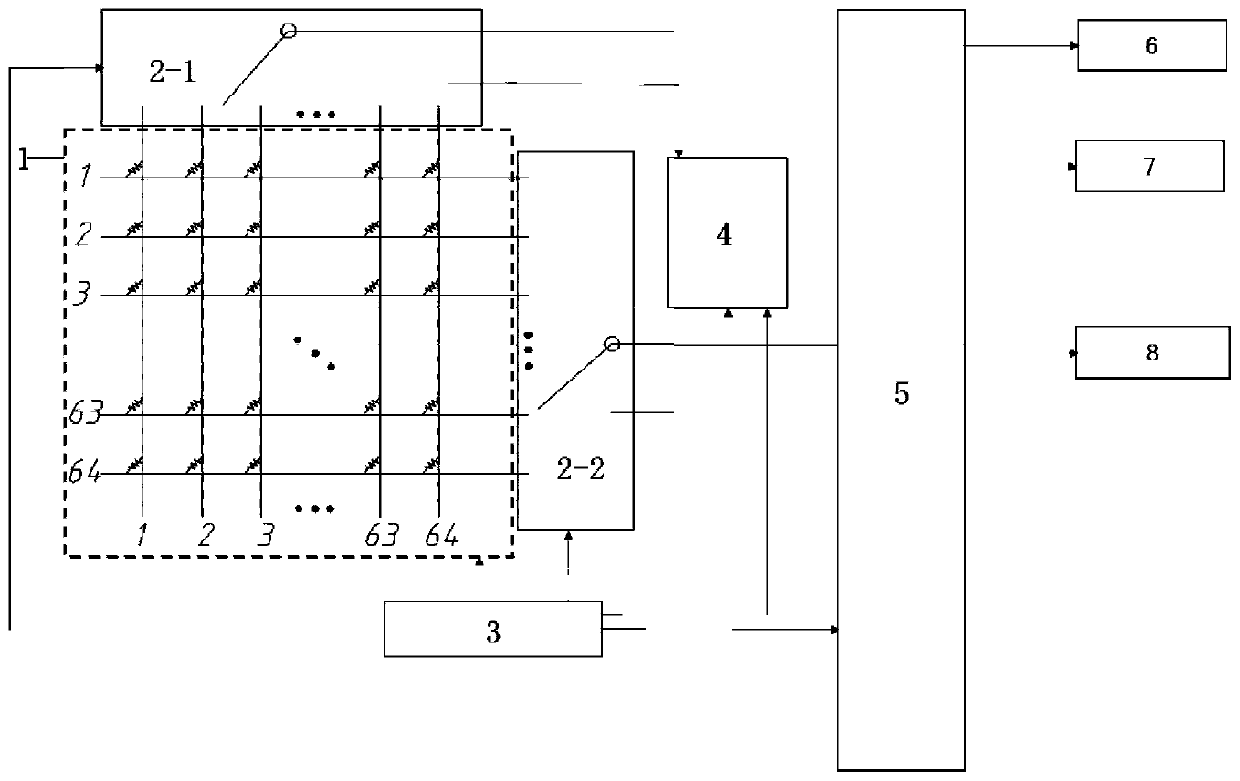

[0017] The effective size of the flexible pressure sensing array is 32 cm×32 cm, with 64 row electrodes and 64 column electrodes, and the intersections of the row and column electrodes and the piezoresistive film constitute 4096 sensing units. The flexible electrode is prepared in batches by screen printing silver paste, and the silver paste is transferred and printed on the PET substrate film and the PET protective film respectively. The shape of the piezoresistive film was drawn using Auto CAD2007, and the piezoresistive film was cut with a size of 1:1 according to the boundary line of the drawing using a laser cutting process with a laser line width of 0.2 mm. The size of each sensing unit is 3 mm × 3 mm, which is slightly larger than the electrode intersection area of 2 mm × 2 mm, which is reserved for assembly margin. There is a connection with a width of 1 mm between the sensor units to ensure that the overall shape of the film remains unchanged after cutting. The sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com