A dry stick device and a method for determining an analyte in a sample

An analyte, device technology, applied in the field of automatic or semi-automatic systems, which can solve the problems of expensive, increased risk of manufacturing failure, uneven impregnation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0133] Preparation of dry sticks

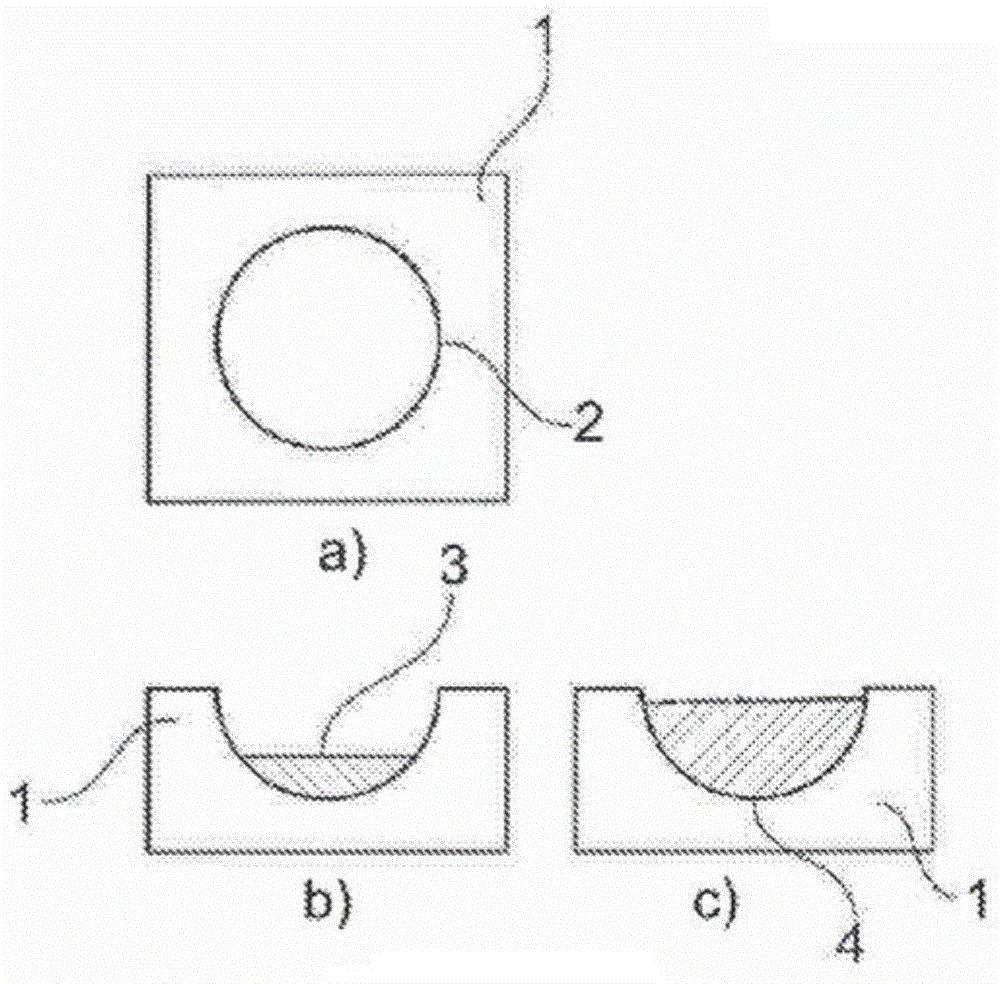

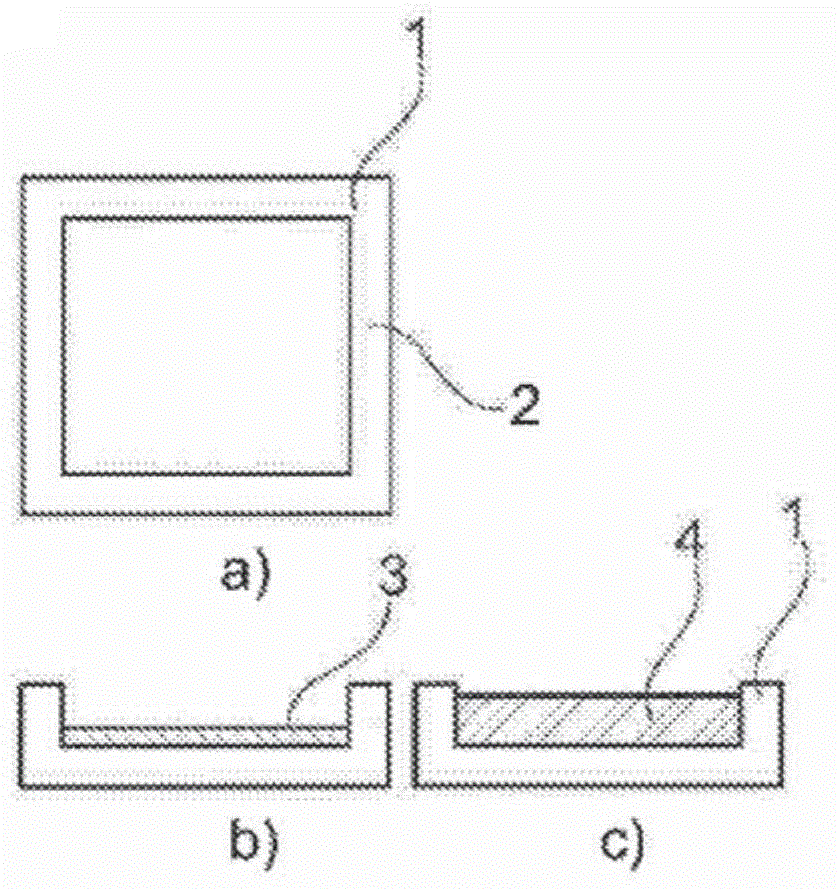

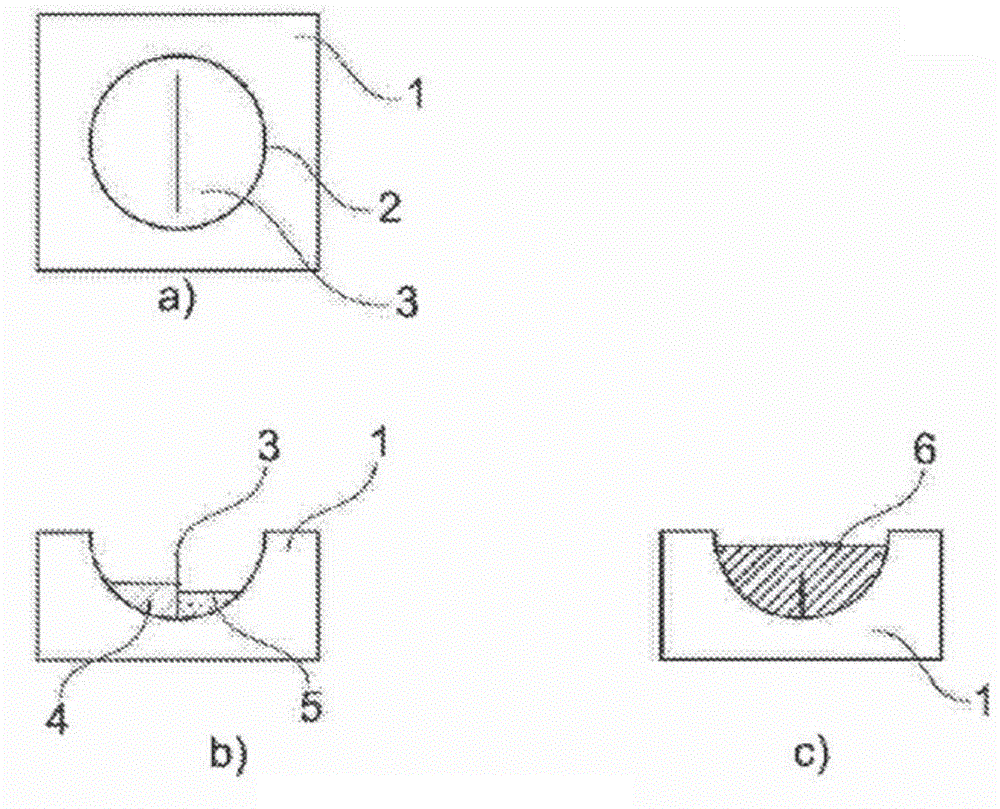

[0134] A comparison between the methods used to make traditional dry sticks and the methods used to make the dry stick structures of the present invention can be found at Figure 7 and 8 seen in.

[0135] Dry stick devices according to the invention may be prepared by any conventional method provided for the preparation of dry stick devices. In a preferred embodiment, the method for providing a dry stick device according to the invention comprises the following steps:

[0136] (i) providing a carrier comprising a cavity;

[0137] (ii) providing at least one dry reagent,

[0138] (iii) applying the at least one dry reagent to the cavity

[0139] And get this dry stick device.

[0140] Comparing the traditional method for the preparation of non-compartmented dry sticks in which one or more reagents are present in the same liner (i.e. the same porous material) with the above-mentioned method of the present invention, the following method...

example 1

[0294] Example 1: Preparation and testing of BHB dry sticks

[0295] Prepare the impregnation solution:

[0296] Dissolve the following reagents one at a time in 3400 mL of 0.1 M Phosphate Buffer pH 8.0:

[0297] 20.0g β-nicotinamide adenine dinucleotide (β-NAD+)

[0298] 9.0g nitro blue tetrazolium (NTB)

[0299] 32 mL of 5% Triton X-100 solution

[0300] 20.0g bovine serum albumin (BSA)

[0301] 400KU ascorbate oxidase (ASO-3 from Amano)

[0302] ·100KU diaphorase (Unitika)

[0303] 50KU hydroxybutyrate dehydrogenase (HBDH from Amano)

[0304] In order to produce a light yellow transparent solution.

[0305] To prepare dry sticks:

[0306] Fill the cavities of multiple separation rods with more than 10 μL of the freshly prepared solution in each cavity. The rods were then dried in a ventilated oven at 40° C. for 1 hour to produce a dry residue (about 250 μg) in each cavity, which stuck to the bottom of the cavity. Then, each separate dry stick obtained was placed...

example 2

[0314] Example 2: Preparation and testing of LDH dry sticks

[0315] Prepare impregnation solution A:

[0316] Dissolve the following reagents one at a time in 2600 mL of 0.1 M Phosphate Buffer pH 8.0:

[0317] 60.0g β-nicotinamide adenine dinucleotide (β-NAD + )

[0318] 30.0g lithium acetate

[0319] 3.0g PEG 20.000

[0320] 30.0g sucrose

[0321] 30 mL of 5% Triton X-100 solution

[0322] 30.0g bovine serum albumin (BSA)

[0323] 300KU Ascorbate Oxidase (ASO-3 from Amano)

[0324] ·600KU diaphorase (Unitika)

[0325] 3.0g nitro blue tetrazolium (NTB)

[0326] In order to produce a light yellow transparent solution.

[0327] Prepare impregnation solution B:

[0328] 450 g TRIS was dissolved in 1080 mL DI water to yield a clear colorless solution with a pH of about 12.

[0329] To prepare dry sticks:

[0330] exist First Fill the cavity of the stick with 8.4 μL of freshly prepared solution A above. The sticks were then dried in a ventilated oven at 40°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com