Rotor assembly for electric machine and method for producing rotor assembly

A technology of rotors and components, which is applied in electric components, electrical components, centering/balancing rotors, etc., can solve the problems of heavy rotor weight, high moment of inertia of motors, and high cost, and achieve the effect of rotor weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

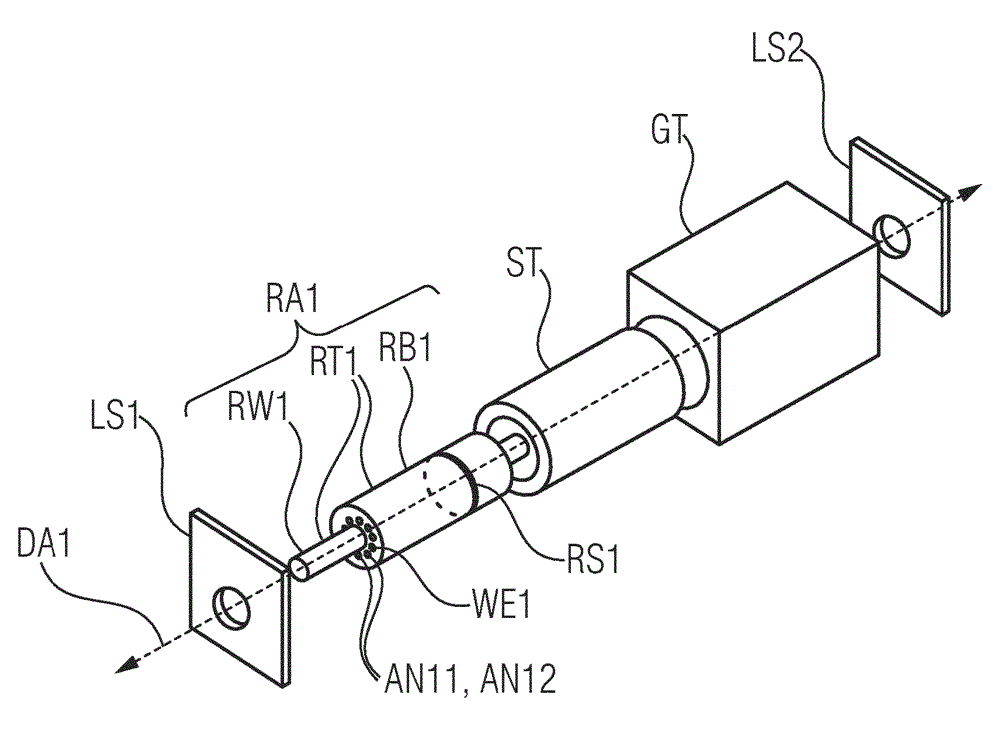

[0043] First, refer to figure 1 , in which an electric machine EM according to a first embodiment of the invention is shown in simplified and schematic form in an exploded view, said embodiment serving as a drive for, for example, a hybrid vehicle or an electric vehicle.

[0044] The electric machine EM comprises a housing part GT for receiving a stator ST, a stator ST, a rotor assembly RA1 together with a rotor shaft RW1 , and first and second end plates LS1 and LS2 for supporting and fixing the rotor shaft RW1 . In the fully assembled state of the electric machine EM, the housing part GT completely surrounds the stator ST and fixes it firmly in motion. The stator ST is of cylindrical design and has a cavity in which the rotor assembly RA1 in the fully installed state of the electric machine EM is supported rotatably and coaxially relative to the stator ST.

[0045] The electric machine EM or the rotor assembly RA1 has an axis of rotation DA1 about which the rotor assembly R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com