Application method of linear cutting inclined surface machining tool

A technology of wire cutting and beveling, which is applied in the field of tooling and fixtures, can solve the problems of inability to process bevels, workpiece positioning accuracy and machining accuracy, etc., and achieve the effect of convenient and practical operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

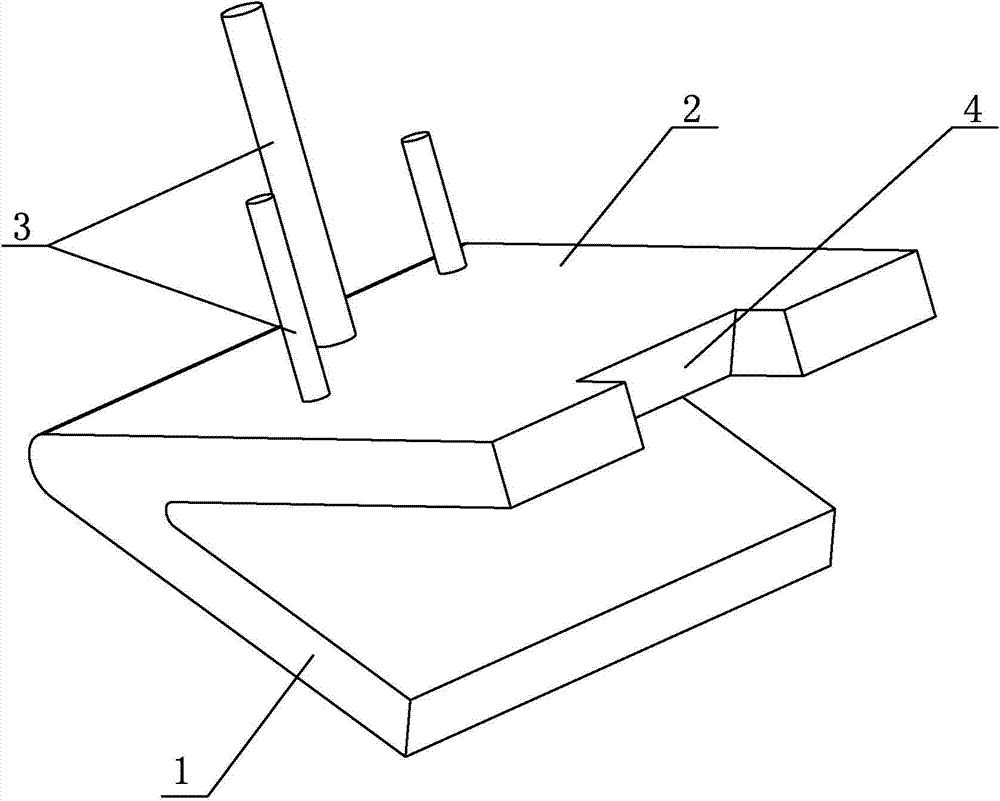

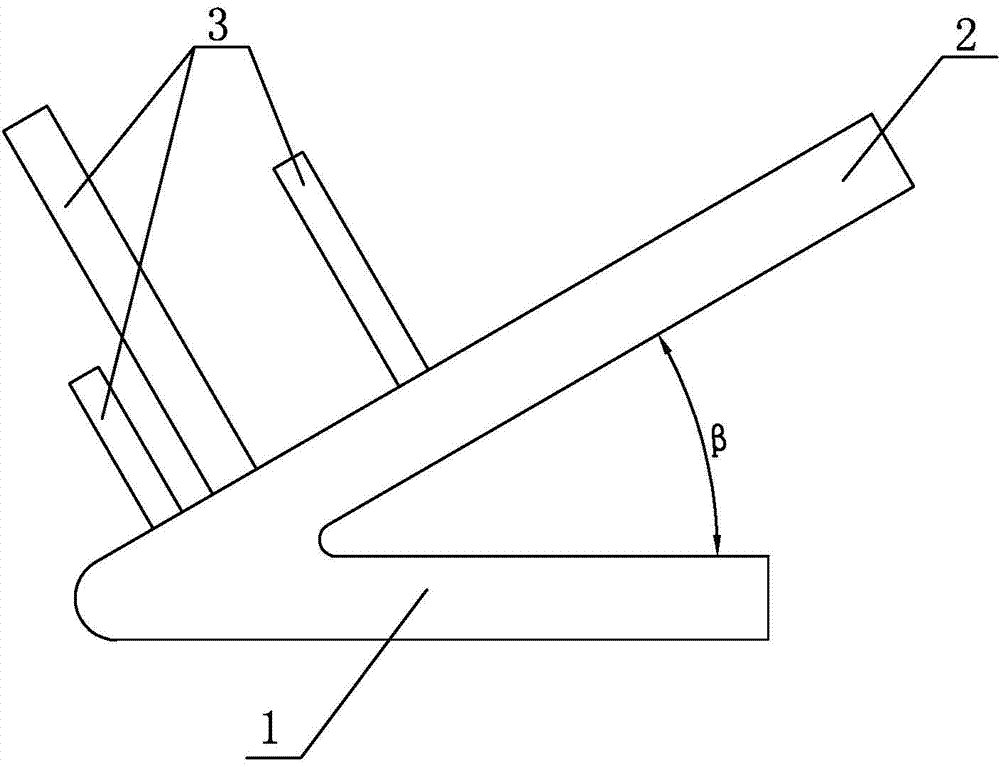

[0014] Such as figure 1 and figure 2 As shown, the present invention includes a base plate 1 and a positioning plate 2. The positioning plate 2 is provided with a positioning column 3 and a wire cutting notch 4. The electrode wire carries out inclined-plane processing on the workpiece at the notch 4, and the positioning column 3 is perpendicular to the positioning plate 2. It is used to position the workpiece; the positioning plate 2 is fixedly connected to one side of the bottom plate 1, and the angle β formed between the positioning plate 2 and the bottom plate 1 is 30° to 45°, and other angles can also be used according to the actual needs of the workpiece;

[0015] The using method of the present invention is as follows:

[0016] The first step is to fix the bottom plate 1 on the console;

[0017] In the second step, the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com