Electric energy assisted braking system with complete coupling function between fraction braking and regenerative braking

A technology of electric power assist and regenerative braking, which is applied in electric braking systems, electric vehicles, transportation and packaging, etc., and can solve problems such as high manufacturing costs, difficulty in obtaining failure protection capabilities from car manufacturers, and high manufacturing costs of brake-by-wire systems , to achieve the effects of small system pressure fluctuations, reduced manufacturing costs, and high pressure regulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

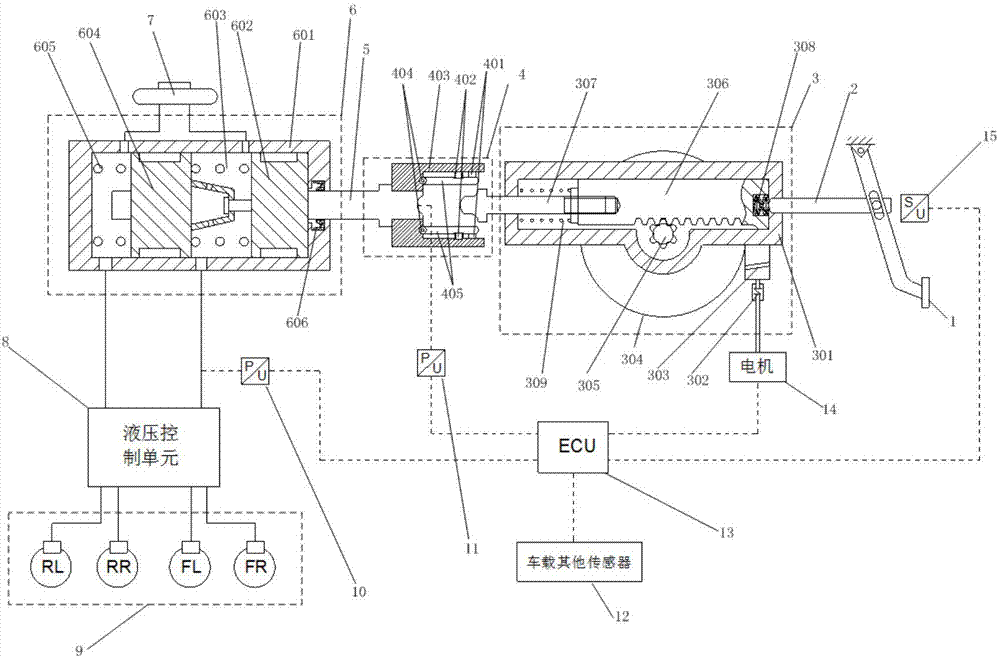

[0031] Such as figure 1 As shown, the electric power assist braking system with the complete decoupling function of friction braking and regenerative braking includes brake pedal 1, push rod 2, electric power assist assembly 3, electromagnet connector 4, master cylinder push rod 5, Master cylinder 6, liquid storage tank 7, hydraulic control unit 8, wheel cylinder 9, master cylinder pressure sensor 10, force sensor 11, other on-board sensors 12, electronic control unit (ECU) 13, motor 14, pedal displacement sensor 15.

[0032]The brake pedal 1 is connected to the push rod 2 through the support pin, the push rod 2 is connected to the rack and pinion mechanism of the electric power booster assembly 3, the motor 14 is connected to the worm gear mechanism of the electric power booster assembly 3, and the electric power booster assembly 3 and An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com