Automatic switching controlling device of two neutral sections for electrified neutral section passing of locomotive

A technology of electrical phase separation and phase B, applied in power lines, vehicle components, transportation and packaging, etc., can solve problems such as unscientific load-shedding principle, unfavorable systematic maintenance management, and the existence of power supply dead zones.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

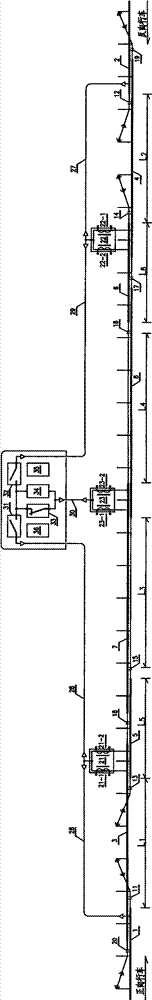

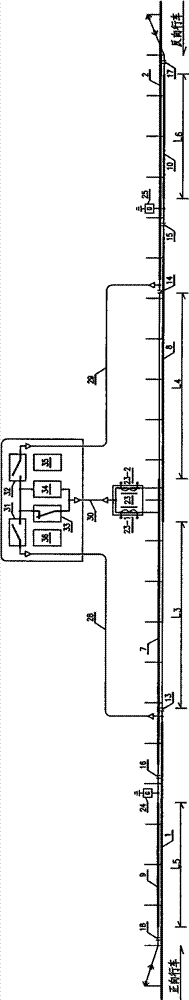

[0007] The first kind of present invention is made up of on-line phase segmentation, three flow mutual signal collectors and a change control box. The phases on the net are segmented, and the catenary of the two power supply arms is anchored through the insulation segment compensation, and the two suspensions are connected by the extension catenary, the neutral catenary and the extension catenary respectively through the insulation segment. Compensation and lowering of the anchors through insulation and segmentation, the pantograph envelope section, the extended supply process section, the two pantograph envelope sections, the extended supply process section, and the pantograph package are formed longitudinally and symmetrically, and the length meets the requirements of the over-phase separation function. Network section: the three current transformers installed on the column are all composed of two current transformers. One end of the two current transformers is connected in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com