Detection method for influences of clamping force on thin-wall piece machining deformation

A technology for processing and testing thin-walled parts, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem of difficulty in determining the clamping force range, and achieve the effect of improving reliability and ensuring safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

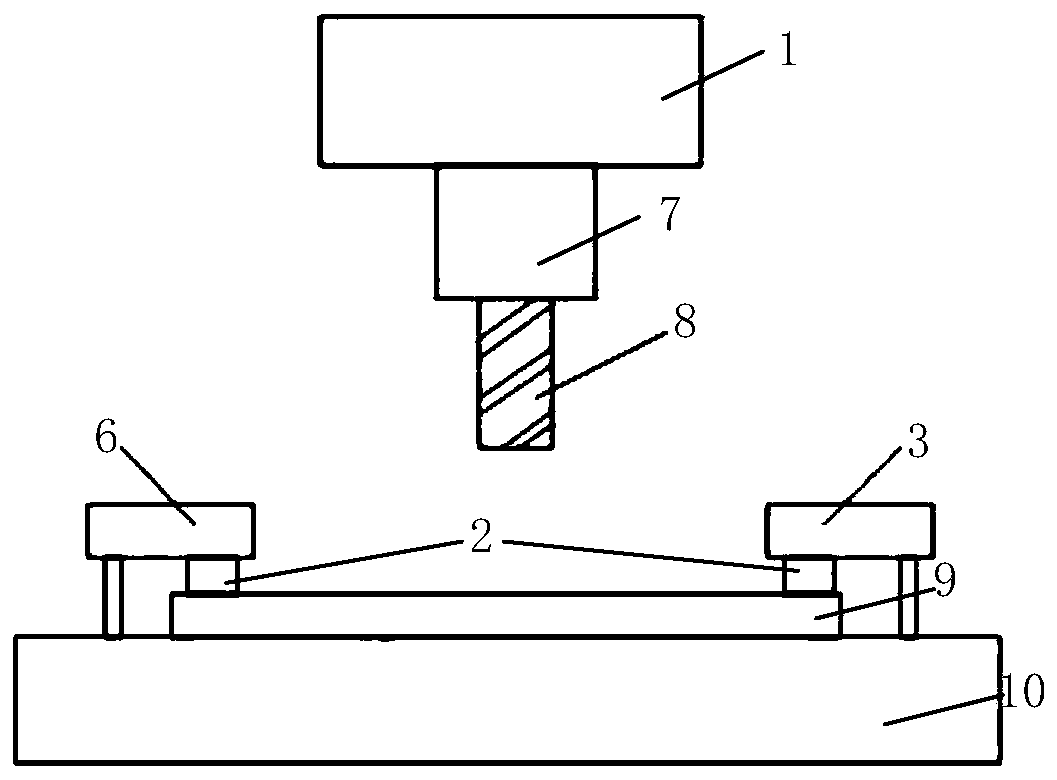

[0027] In order to understand the present invention more clearly, the present invention will be further described in detail in conjunction with the accompanying drawings.

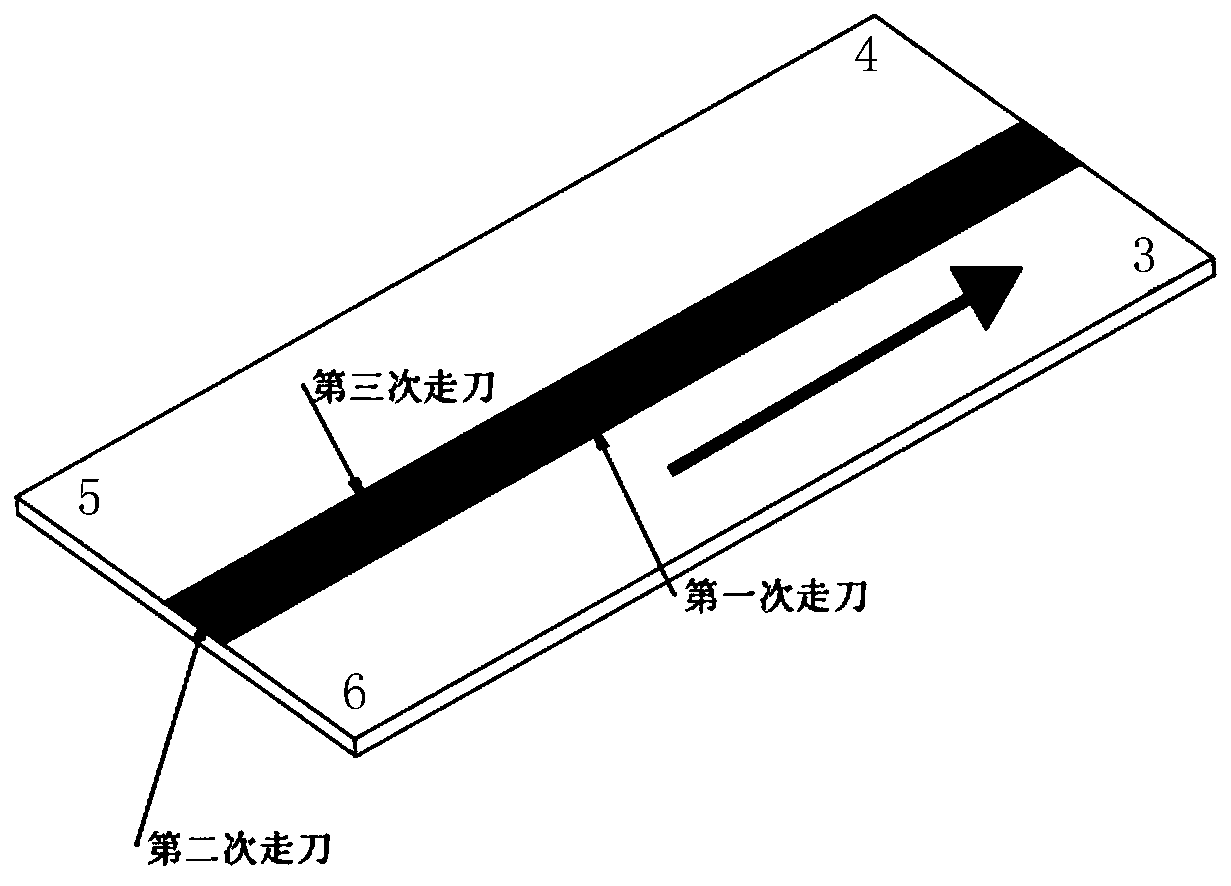

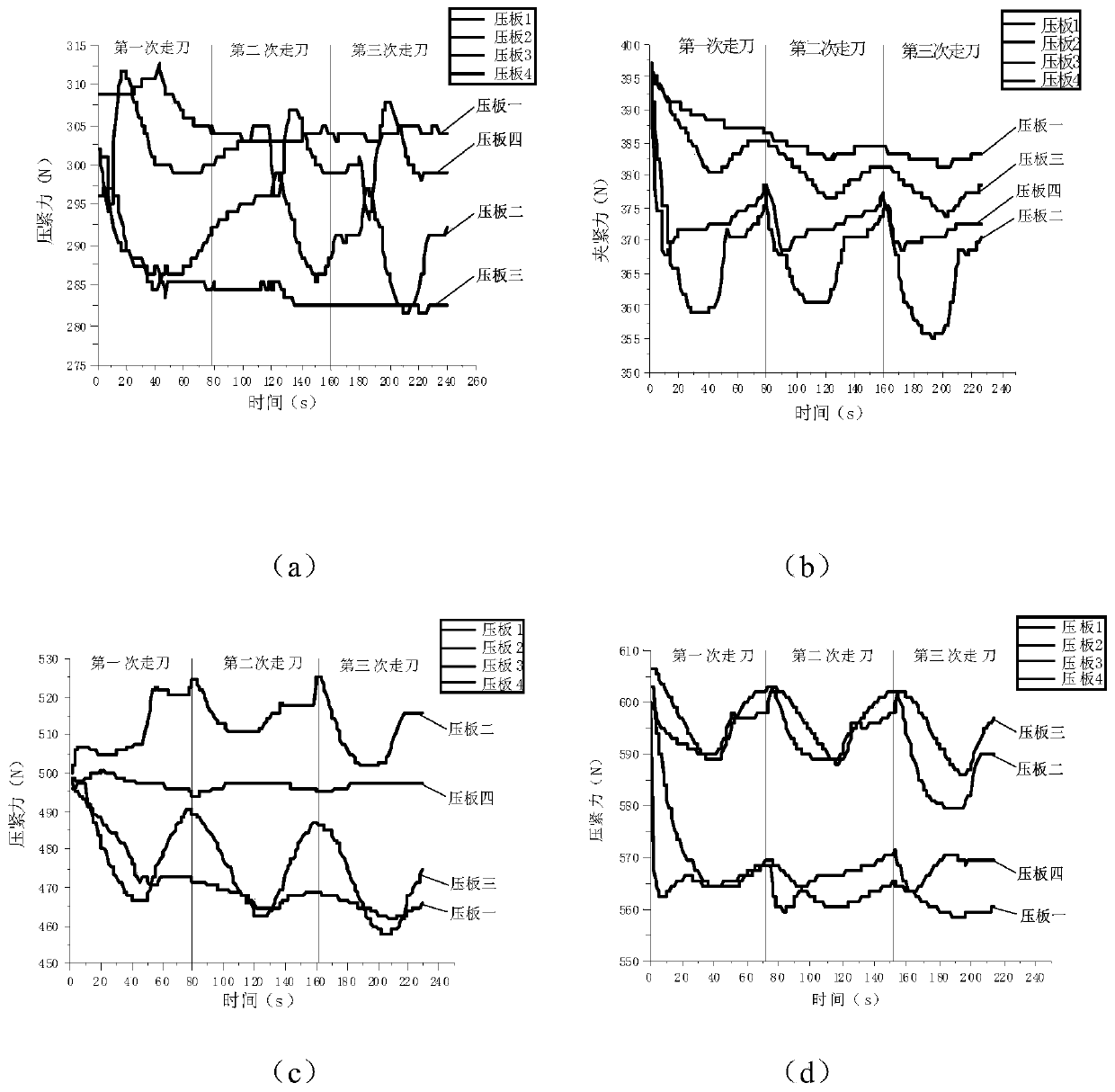

[0028] Refer below Figure 1-6 A method for detecting the effect of clamping force on machining deformation of a thin-walled part according to an embodiment of the present invention will be described. The method comprises the steps of:

[0029] Step 1: Calculate the basic conditions to be satisfied by the clamping force of the thin-walled part 9;

[0030] Step 2: Select 3-7 clamping forces, and carry out clamping under different clamping forces;

[0031] Step 3: Carry out a milling experiment on the thin-walled part 9 by adopting the clamping method of surface support and four-point clamping;

[0032] Step 4: Use the pressure sensor 2 to measure the clamping force, and record the change of the clamping force during the milling process;

[0033] Step 5: After milling, use a three-coordinate measuring mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com