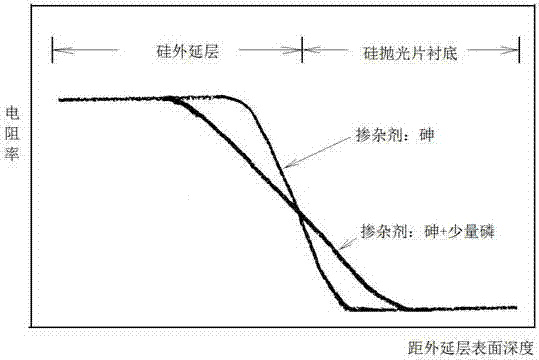

Phosphorus, arsenic and antimony co-doped N-type heavily-doped Czochralski silicon single crystal and silicon epitaxial wafer thereof

A technology of Czochralski silicon single crystal and co-doping, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of semiconductor device yield loss, epitaxial lattice mismatch, etc., and achieve the elimination of mismatch Effect of Miswire Defect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the N-type heavily doped Czochralski silicon single crystal co-doped with phosphorus, arsenic and antimony has the following steps:

[0028]1) Melting of polysilicon: Put the quartz crucible into the Czochralski silicon single crystal furnace, then fill the quartz crucible with polysilicon, vacuumize it, and melt the polysilicon with electricity, adjust the input power to stabilize the temperature of the silicon melt at 1460±20 ℃;

[0029] 2) Add phosphorus as the main doping element: put the weighed red phosphorus into the quartz cup, then hang the quartz cup in the quartz bell jar, and hang the quartz bell jar on the seed clamp of the pulling room of the silicon single crystal furnace On the head, vacuumize, open the isolation valve at the lower part of the lifting chamber, and lower the quartz bell jar to a position 5-10 mm away from the surface of the silicon melt in the quartz crucible to completely volatilize the dopant and be absorbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com