A method for preparing silicon nanostructure material under alternating electric field

A technology of alternating electric field and structural materials, applied in nanotechnology, chemical instruments and methods, crystal growth, etc., can solve the problems of low preparation efficiency, low structural accuracy of silicon nanostructured materials, and inability to prepare silicon nanostructured materials. , to improve the directional corrosion rate, facilitate electron transfer, and maintain the effect of concentration uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

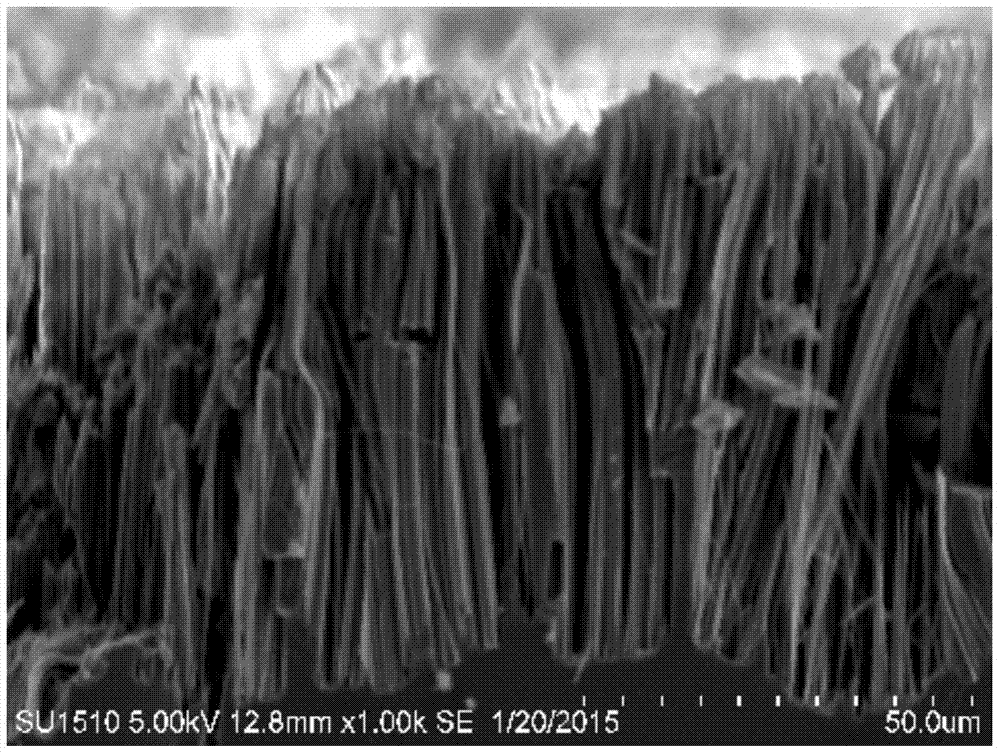

[0028] Embodiment 1, preparation silicon nanowire

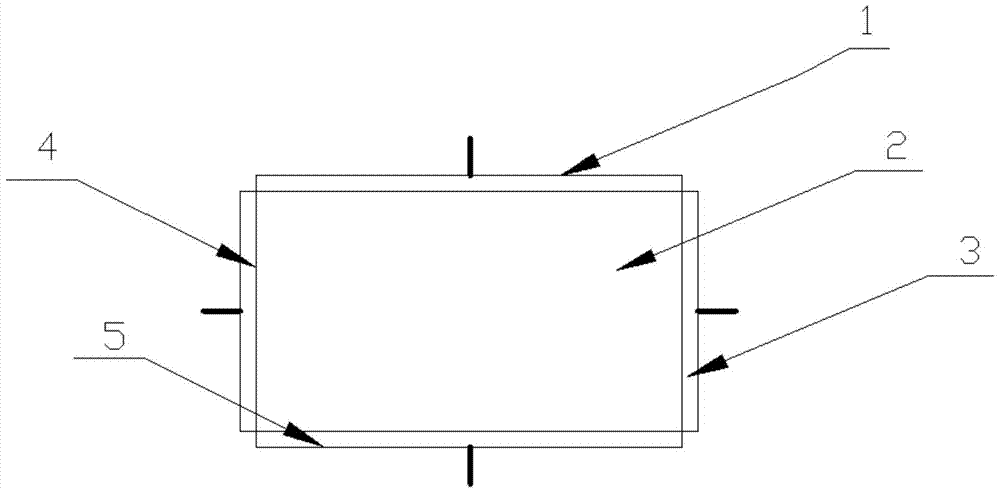

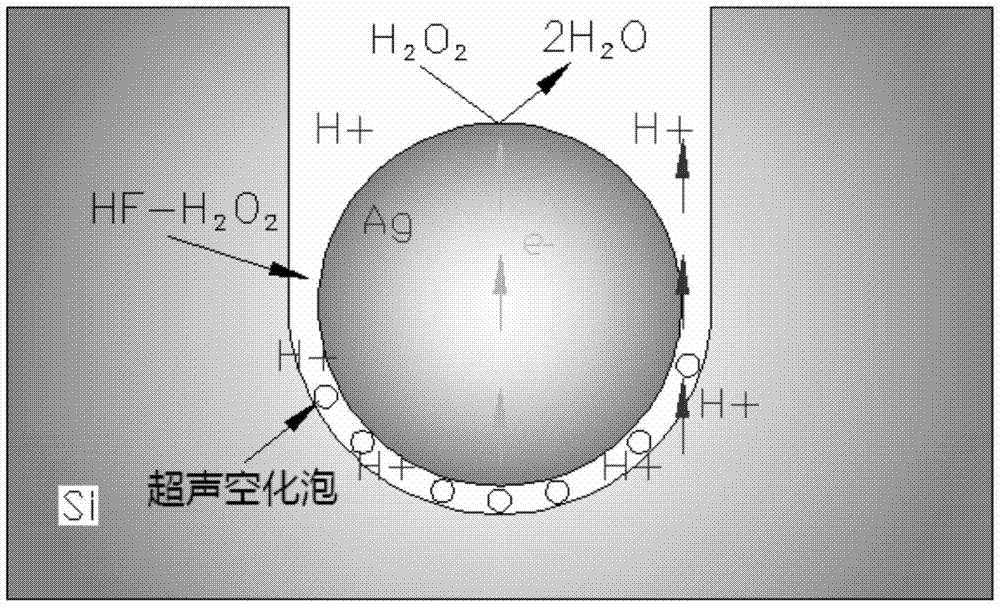

[0029] Put the clean bulk silicon and the pasted inert electrode into the corrosion solution. The composition ratio of the corrosion solution is hydrofluoric acid: hydrogen peroxide: silver nitrate: water, and the volume ratio is 12:1:1:36. Three pairs of inert electrodes are connected, the electric field strength is 300v / m-1000v / m, and the frequency is 40kHz; after being corroded for 120min at 15°C-25°C, it is taken out and cleaned to prepare a silicon nanowire structure.

Embodiment 2

[0030] Embodiment 2, preparation silicon nanowire

[0031] Put the clean bulk silicon and the pasted inert electrode into the corrosion solution. The composition ratio of the corrosion solution is hydrofluoric acid: hydrogen peroxide: silver nitrate: water, and the volume ratio is 12:1:1:36. Three pairs of inert electrodes are connected, the electric field strength is 300v / m-1000v / m, and the frequency is 40kHz; after being corroded for 120min at 15°C-25°C, it is taken out and cleaned to prepare a silicon nanowire structure.

Embodiment 3

[0032] Embodiment 3, preparation of 3D nano-silicon structure (arc structure prepared inside bulk silicon)

[0033] Put the clean bulk silicon and the pasted inert electrode into the corrosion solution. The composition ratio of the corrosion solution is hydrofluoric acid: hydrogen peroxide: silver nitrate: water, and the volume ratio is 10:1:1:38. Three pairs of inert electrodes are turned on at the same time, and the three electric field strengths are 300v / m-1000v / m respectively, and the frequency is 28kHz; after being corroded for 90min at 15°C-25°C, they are taken out and cleaned to prepare a 3D nano-silicon structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com