Exhaust gas treatment device and exhaust gas treatment system

A waste gas treatment device and waste gas technology, which are applied in the directions of gas treatment, combustion product treatment, combustion method, etc., can solve the problems of increasing initial cost and maintenance cost, and achieve the goal of reducing the number, promoting diffusion, and ensuring concentration uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] An exhaust gas treatment system to which an exhaust gas treatment device according to an embodiment of the present invention is applied will be described with reference to the drawings.

[0052] It should be noted that, due to the structure and Figure 5 The shown exhaust gas treatment systems have the same structure, so in this embodiment, only the structure of the exhaust gas treatment device will be described.

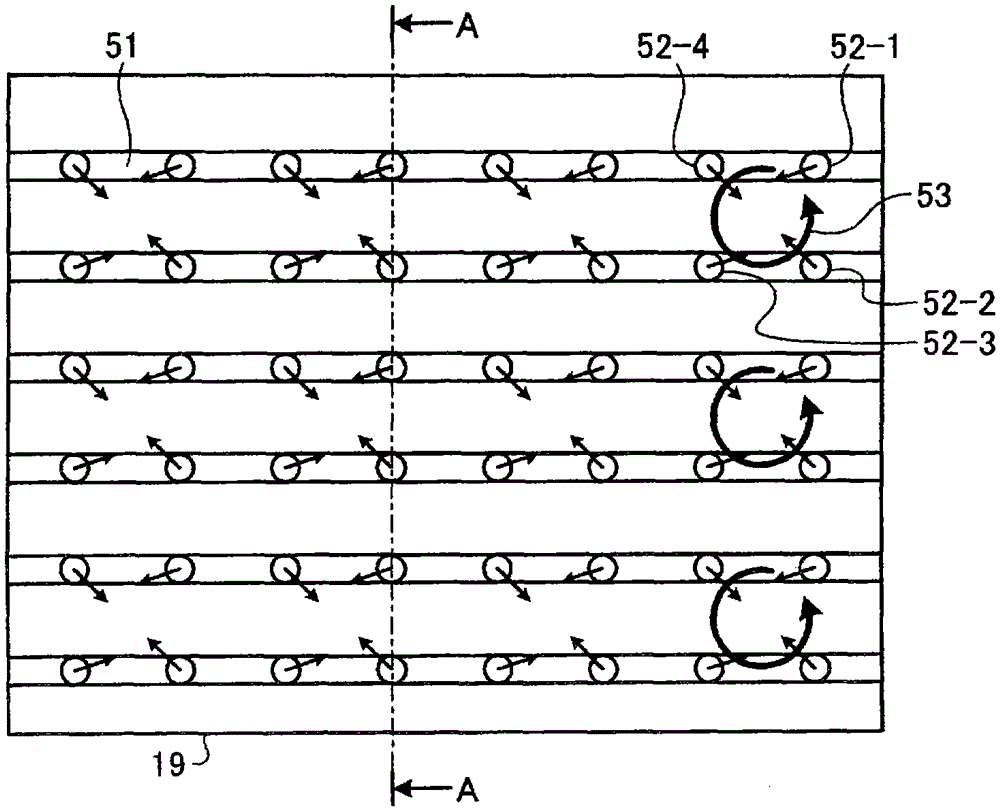

[0053] Picture 1-1 It is a schematic diagram showing the spray nozzle in the flue of the exhaust gas treatment device of the embodiment, Figure 1-2 is its A-A view. It should be noted that due to the structure of the exhaust gas treatment system and Figure 5 are the same, so their description is omitted.

[0054] Such as Picture 1-1 and Figure 1-2 As shown, the exhaust gas treatment device of this embodiment has at least one denitration catalyst layer, and the denitration catalyst layer removes nitrogen oxides in the exhaust gas 12 from the boiler 11...

Embodiment 2

[0062] An exhaust gas treatment device according to an embodiment of the present invention will be described with reference to the drawings.

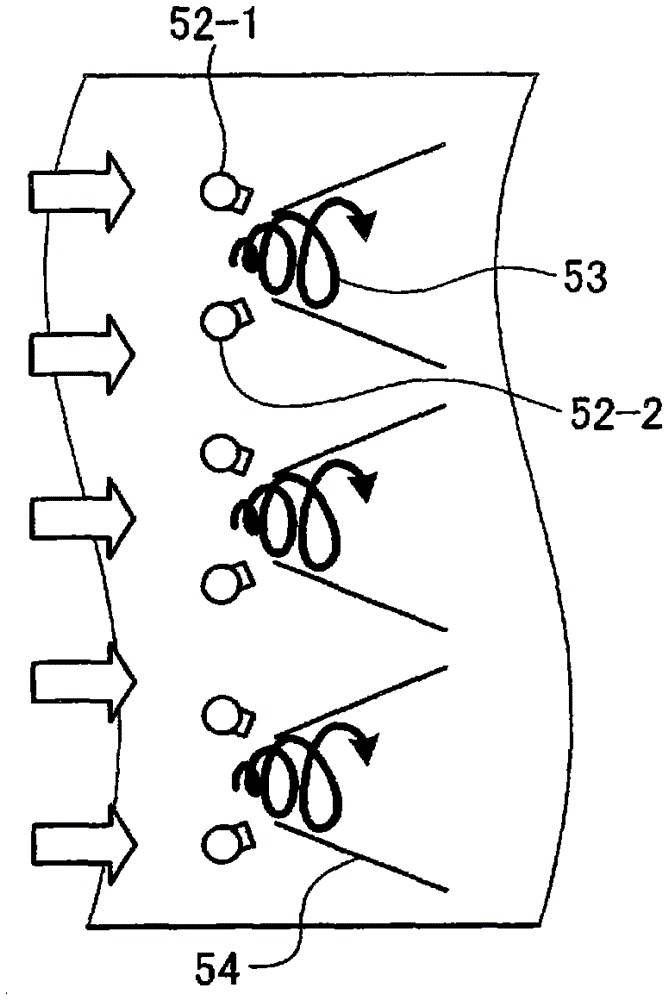

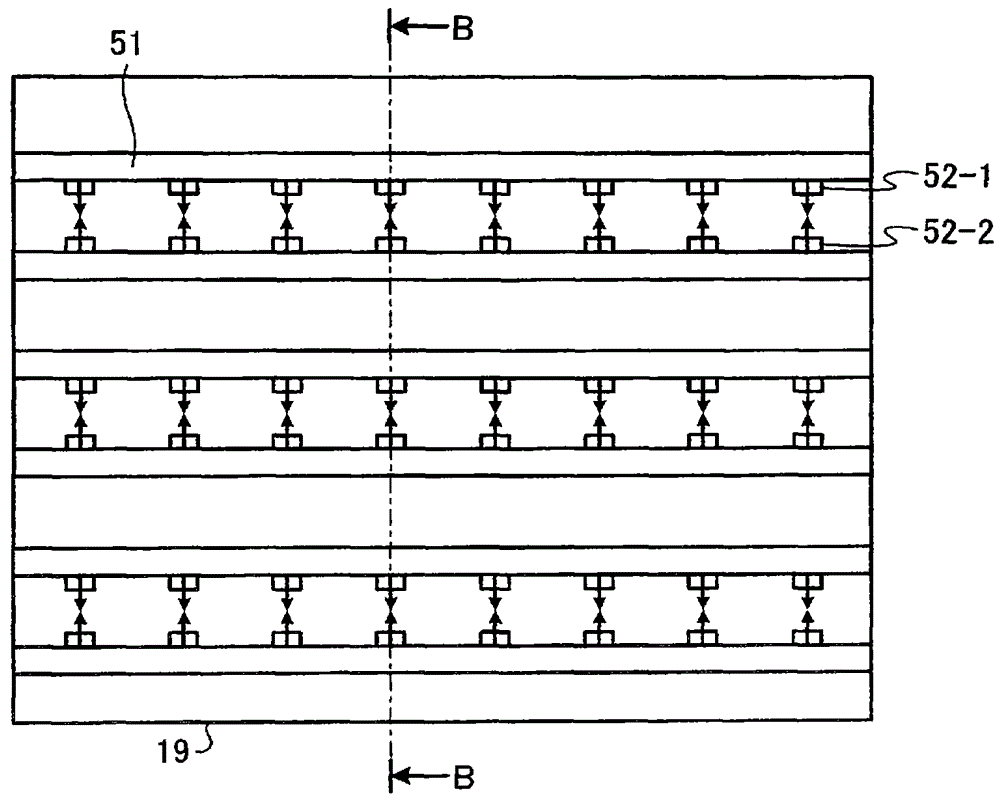

[0063] diagram 2-1 It is a schematic diagram showing the spray nozzle in the flue of the exhaust gas treatment device of the embodiment, Figure 2-2 is its B-B direction view. Figure 2-3 It is a schematic diagram showing the facing state of spray nozzles. It should be noted that due to the structure of the exhaust gas treatment system and Figure 5 are the same, so their description is omitted.

[0064] Such as diagram 2-1 , Figure 2-2 and Figure 2-3 As shown, in this embodiment, the gas diffusion promotion mechanism includes a spray pipe joint 51 arranged in the flue 19 and inserted perpendicularly to the gas flow direction of the flue 19, and a pipe joint 51 arranged on the spray pipe. The plurality of spray nozzles 52 of the joint 51 face each other, and collide the jet streams with each other.

[0065] In this example, i...

Embodiment 3

[0070] An exhaust gas treatment device according to an embodiment of the present invention will be described with reference to the drawings.

[0071] Figure 3-1 It is a schematic diagram showing the spray nozzle in the flue of the exhaust gas treatment device of the embodiment, Figure 3-2 is its C-C direction view, Figure 3-3 is a perspective view of a swirling diffuser. It should be noted that due to the structure of the exhaust gas treatment system and Figure 5 are the same, so their description is omitted.

[0072] Such as Figure 3-1 to Figure 3-3 As shown, in this embodiment, the gas diffusion promotion mechanism includes a spray pipe joint 51 arranged in the flue 19 and inserted perpendicularly to the gas flow direction of the flue 19, and a pipe joint 51 arranged on the spray pipe. The spray nozzle 52 of the joint 51 is provided with a swirling diffuser plate 55 on the opening side of the spray nozzle 52 to form a vertical vortex along the gas flow direction.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com