Cycle microcosmic truss insert and manufacturing method of cycle microcosmic truss structure body

A technology of structures and trusses, applied in building structures, building components, buildings, etc., can solve the problems of high manufacturing costs, low manufacturing efficiency, and cumbersome steps of microscopic trusses, and achieve low manufacturing costs, improved structural utilization, and high model various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

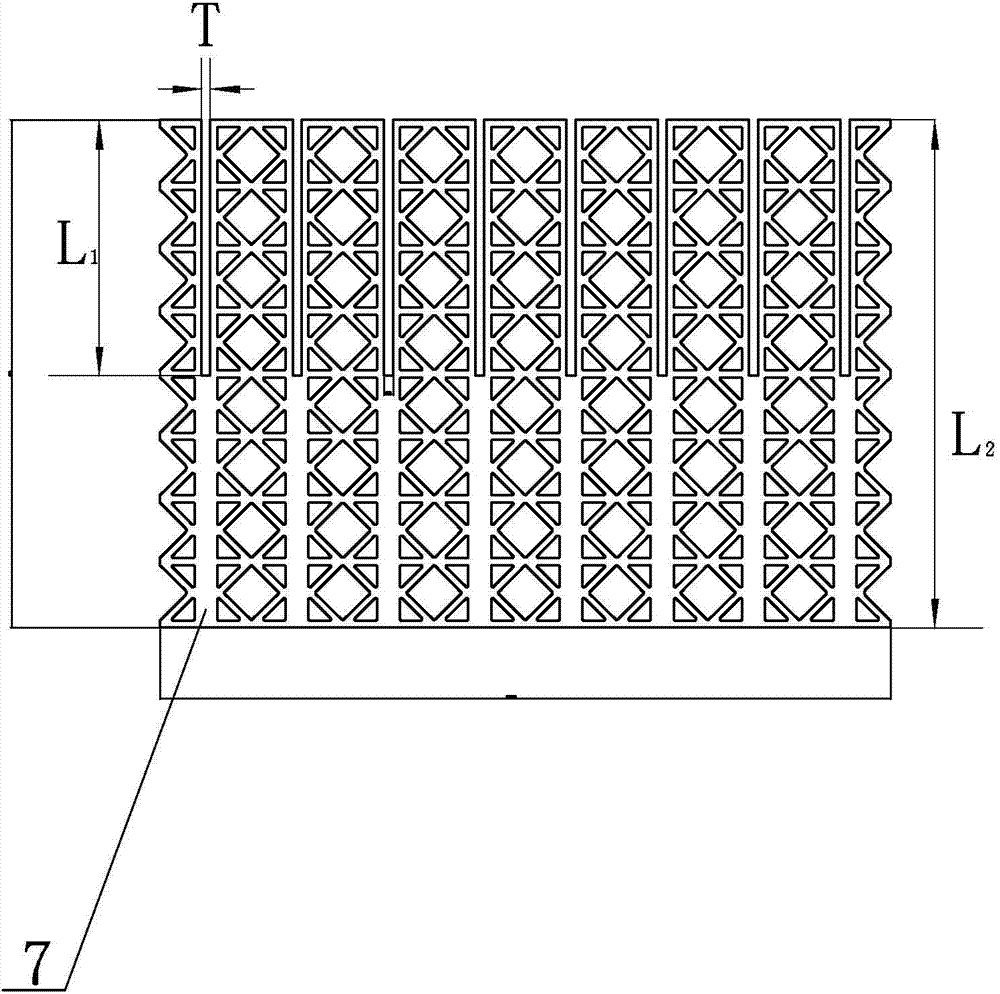

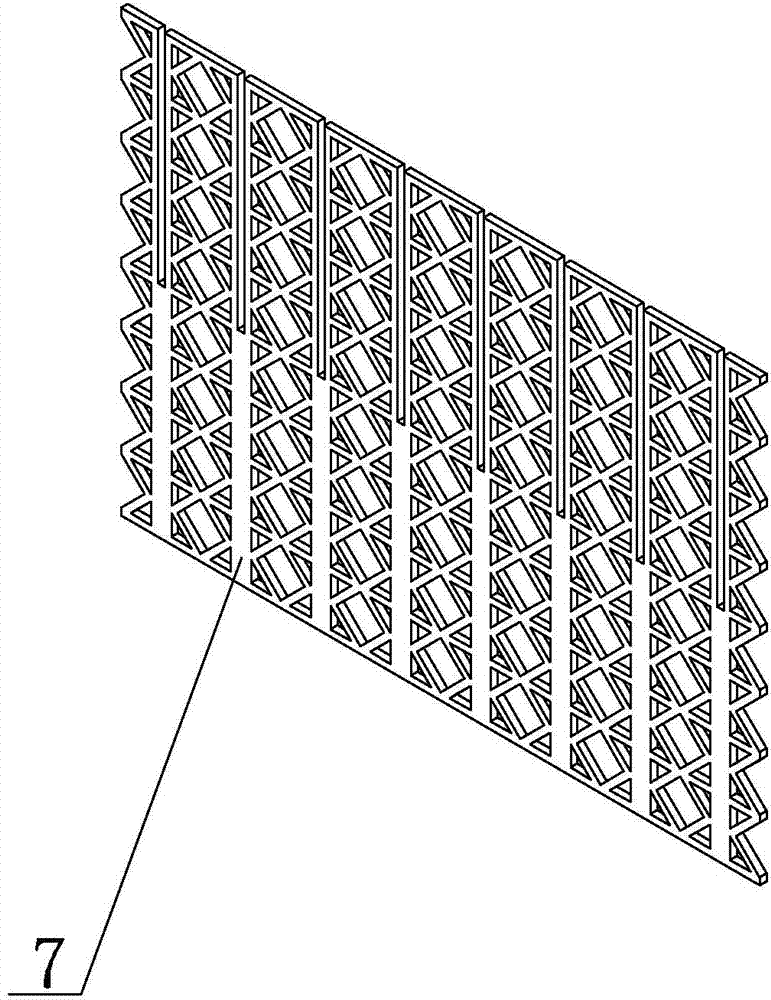

[0025] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, this embodiment includes the insert body 7, the insert body 7 is a rectangular piece, and the insert body 7 is uniformly processed from one long side to the central axis of the insert body 7 in the length direction There are multiple interlocking notches, the length of each interlocking notch is L 1 , the width of each interlocking notch is T, and the length of the wide side of the insert body 7 is L 2 , the length of each interlocking notch L 1 Equal to the length L of the wide side of the rectangular sheet 2 The width T of each interlocking notch is equal to the thickness of the insert body 7, and a plurality of holes are uniformly processed between two adjacent interlocking notches. In this embodiment, a plurality of holes can be arranged in the same line, and the length of the arrangement of the plurality of holes is equal to the length of the broad side of the insert bod...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination figure 1 with figure 2 To illustrate this embodiment, the rectangular sheet in this embodiment is a sheet made of carbon fiber reinforced composite material, stainless steel or PVC. Rectangular sheets of different materials form periodic microscopic truss inserts through different processing methods. Processing methods include 3D printer printing, engraving, cutting or stamping. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

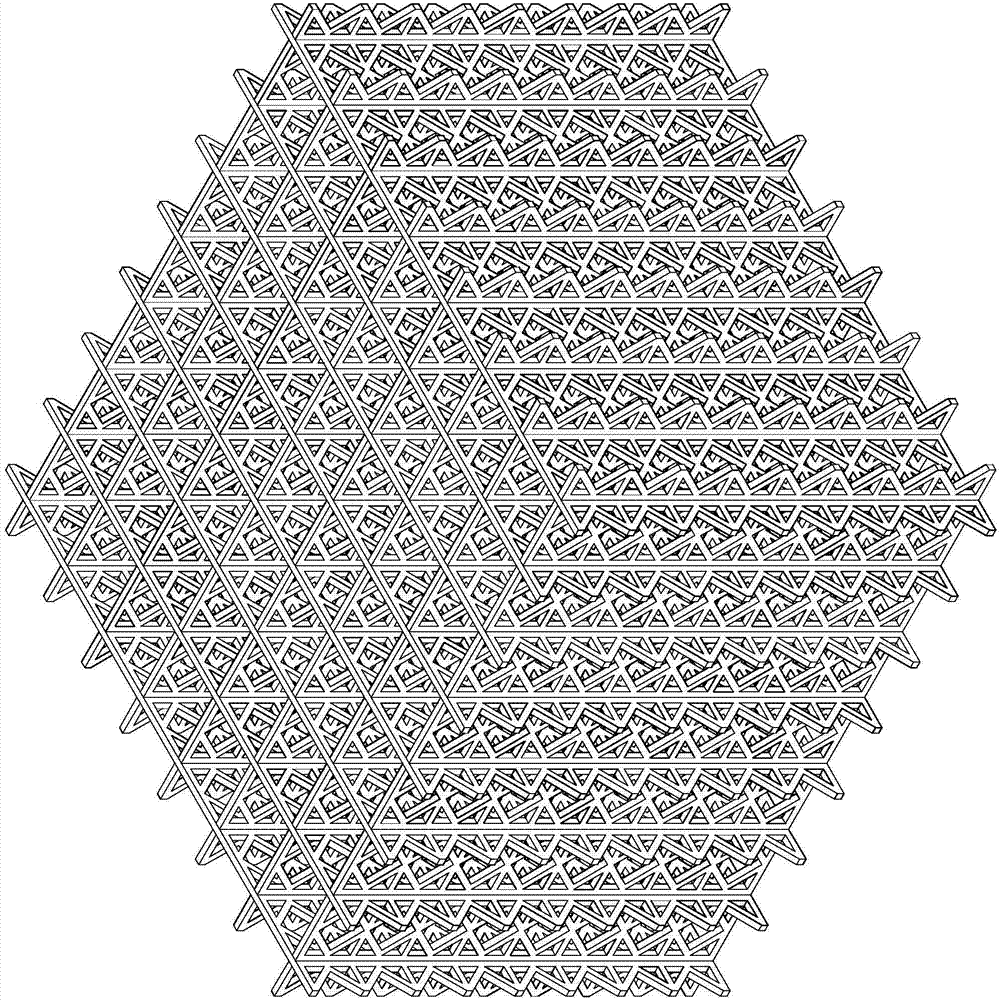

[0027] Specific implementation mode three: combination figure 1 , figure 2 with image 3 Describe this embodiment. In this embodiment, a method of manufacturing a periodic micro-truss structure by using the periodical micro-truss inserts described in the first specific embodiment is connected according to the following steps:

[0028] Step 1: Hole machining: machining multiple holes of different shapes on one insert body 7;

[0029] Step 2: Processing of interlocking notches: on the insert body 7, a plurality of interlocking notches are uniformly processed from one long side to the central axis in the length direction of the insert body 7, and the length of each interlocking notch is L 1 Equal to the length L of the wide side of the rectangular sheet 2 The width T of each interlocking notch is equal to the thickness of the insert body 7. After processing a plurality of interlocking notches, the periodic microscopic truss insert can be obtained;

[0030] Step 3: Interlocki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com