Construction method for antimagnetic stainless steel bars in antimagnetic area of transformer room

A transformer room and construction method technology, applied to the processing of building materials, structural elements, building components, etc., can solve problems such as incorrect construction methods, inadequate insulation and binding, and insulation parts washout or displacement, etc., to achieve improvement The effect of construction quality, high cost solution, and collapse avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

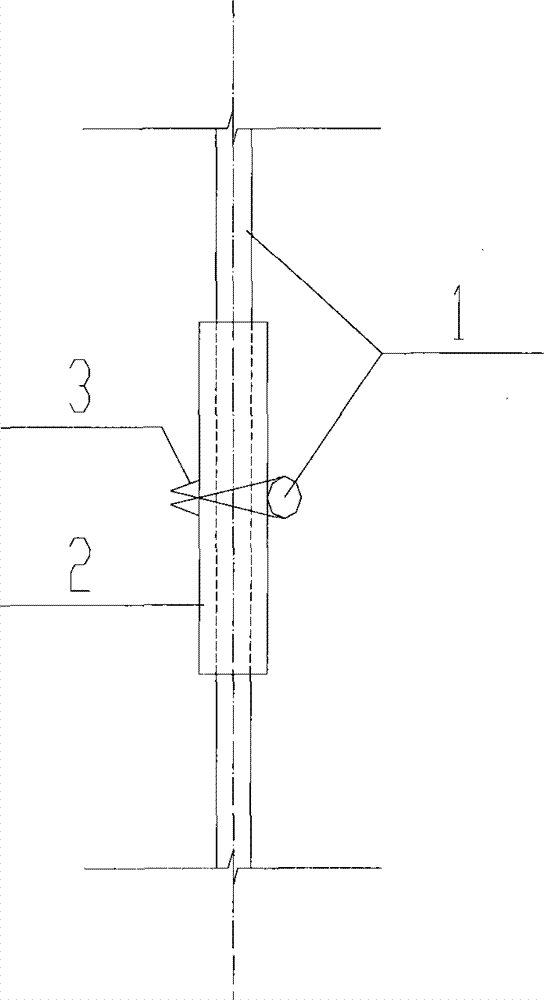

[0030] exist figure 1 In the process, the antimagnetic stainless steel bar 1 and the antimagnetic stainless steel bar 1 cannot be in contact with each other, and the plastic film 2 is cut into thin strips, and wound on several intersection points of the antimagnetic stainless steel bar 1 and another antimagnetic stainless steel bar 1, and then the insulating rope 3 Bind the two antimagnetic stainless steel bars 1 firmly.

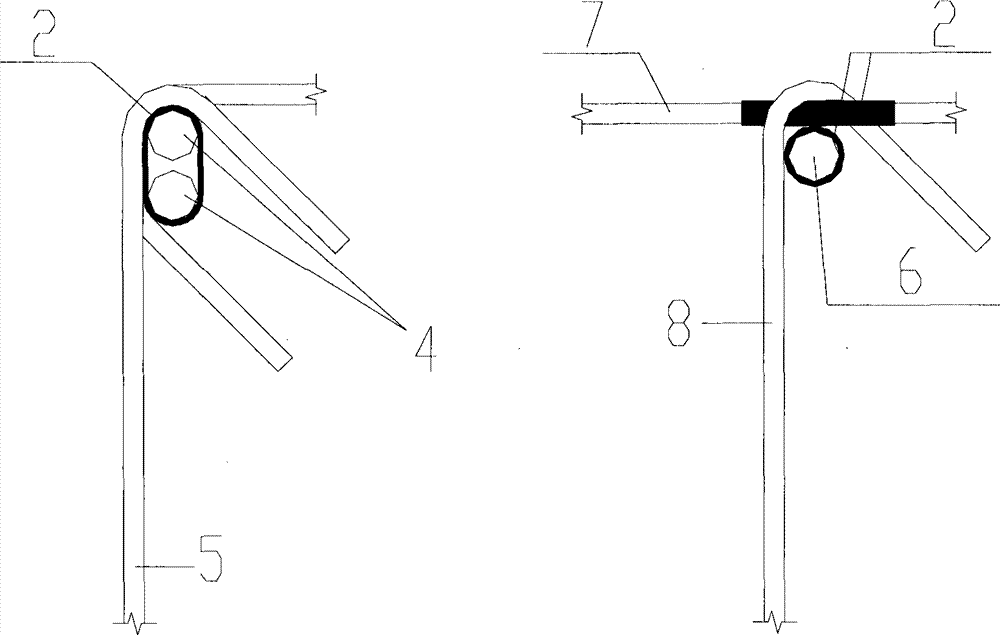

[0031] exist figure 2 In the shown embodiment, the plastic film 2 is cut into thin strips and wound on the lapped beam and column longitudinal reinforcement 4 to ensure insulation from the closed stirrup 5 of the beam and column. Wrap the plastic film 2 on several intersections of the vertical steel bar 6 and the horizontal steel bar 7 of the shear wall respectively to ensure insulation from the tie bar 8 .

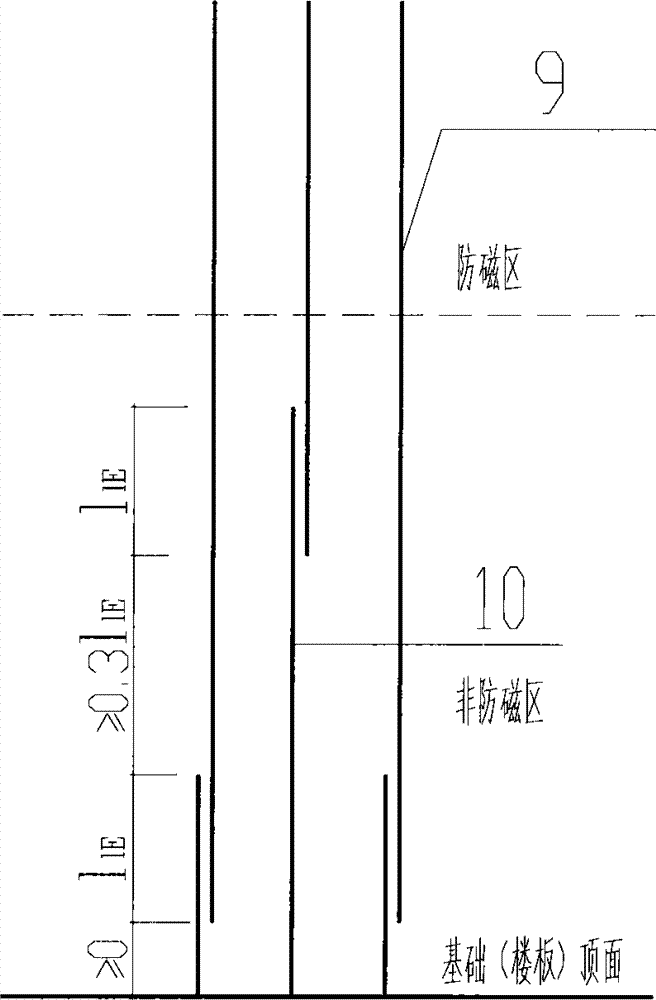

[0032] exist image 3 In another embodiment shown, the shear wall in the antimagnetic area, the vertical steel bar 9 of the column and the shear wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com