Wood composite door and biochemical treatment method for boards for manufacturing same

A technology for fitting doors and panels, which can be used in door leaf, impregnated wood, manufacturing tools, etc., and can solve the problems of formaldehyde pollution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Such as figure 1 As shown, the set door provided in this embodiment includes: a door leaf, and the door leaf includes a door leaf panel 101;

[0053] The board for making the door panel 101 is the door panel 101 board impregnated with biological protease obtained through a dipping process.

[0054] The above suit door impregnates the biological protease into the plate of the door panel 101 through the dipping process, and uses the door panel 101 plate impregnated with the biological protease to make the door panel 101. When the formaldehyde in the air contacts the door panel 101, the door The biological protease in the panel 101 absorbs and decomposes the formaldehyde in the air, so that the suit door can absorb and decompose the formaldehyde contained in the suit door and indoor air for a long time.

[0055] The biochemical treatment method for the plate used to make the door panel 101 includes: immersing the plate in an aqueous solution of biological protease to obta...

Embodiment 2

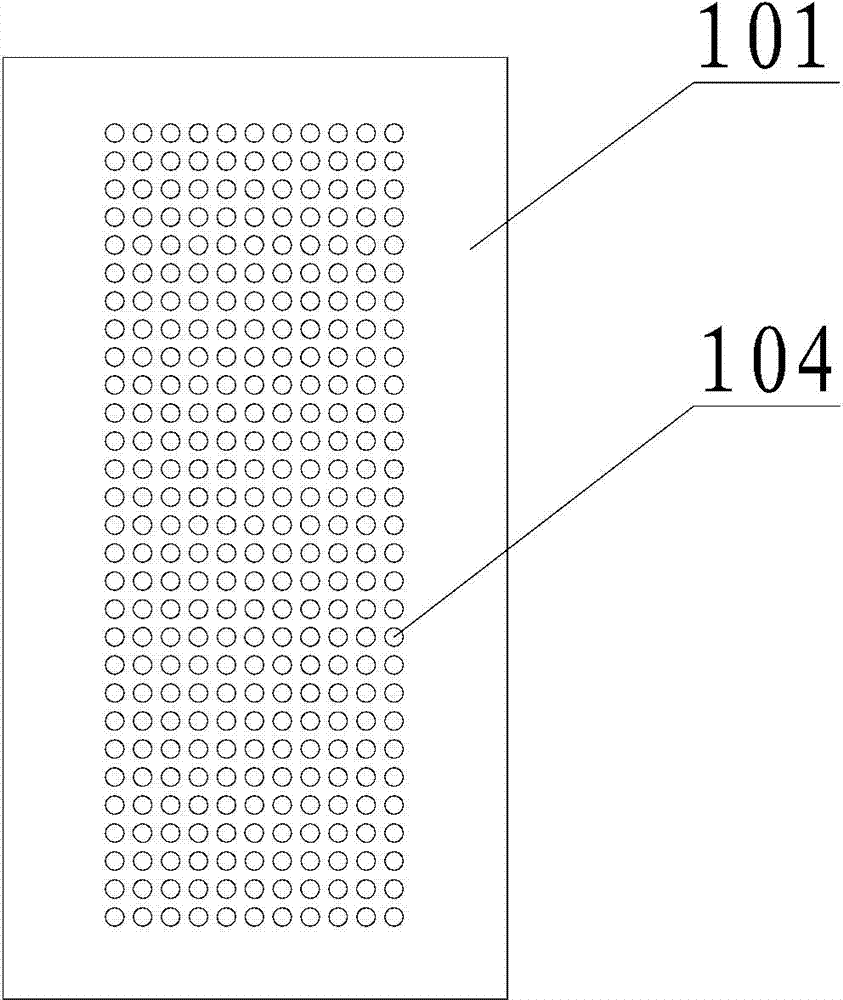

[0064] Such as Figure 2-7 As shown, the suit door provided in this embodiment includes: a door leaf, and the door leaf includes a door leaf panel 101 and a wooden beam 102 as a door leaf skeleton;

[0065] The plate for making the door panel 101 is the door panel 101 plate impregnated with biological protease obtained by the dipping process, and the plate for making the wooden frame 102 is the plate impregnated with a non-photocatalyst obtained by the dipping process.

[0066] The door panel is covered on the outer surface of the wooden beam 102, and the wooden beam 102 and the door panel form several adsorbent filling bins 103 inside the door leaf, and the adsorbent filling bins 103 are filled with There is an adsorbent 110, and the door panel is provided with an adsorption hole 104 for indoor air to enter the adsorbent filling chamber 103; the adsorbent 110 is pure nano-diatom, bamboo charcoal loaded with titanium dioxide, activated carbon loaded with titanium dioxide and ...

Embodiment 3

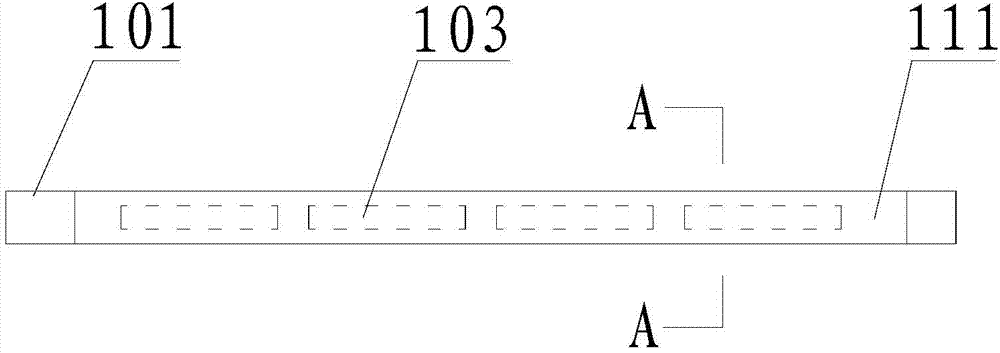

[0079] Such as Figure 8 and Figure 9 As shown, the suit door provided by the present embodiment includes: a door leaf, and the door leaf includes a door leaf panel 101, a breathable material box 109, a filling bin cover plate 111 and a wooden frame 102 as a door leaf skeleton;

[0080] The plate for making the door panel 101 is the door panel 101 plate impregnated with bio-protease obtained by the dipping process, and the plate for making the wooden frame is the plate obtained by the impregnating process for impregnating photocatalyst.

[0081]The wooden frame 102 includes a door frame frame and several door core frame 107, and the door frame frame includes two door vertical frame 106, a door upper dock frame 105 and a door lower dock frame Fang 108; the two ends of the upper pier wooden square 105 of the door leaf are respectively connected with the tops of the two vertical side wooden squares 106 of the door leaf, and the two ends of the lower dock wooden square 108 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com