Wireless sensor-based mine environment harmful gas detection system

A wireless sensor and harmful gas technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of low reliability, low accuracy, and complex components, and achieve the effect of improving real-time performance, accuracy, and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

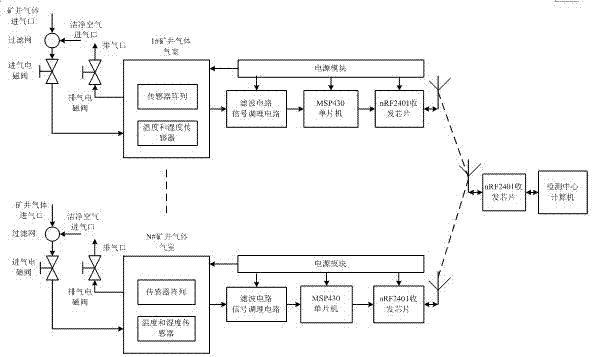

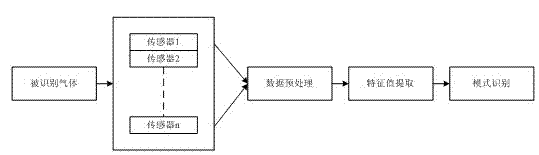

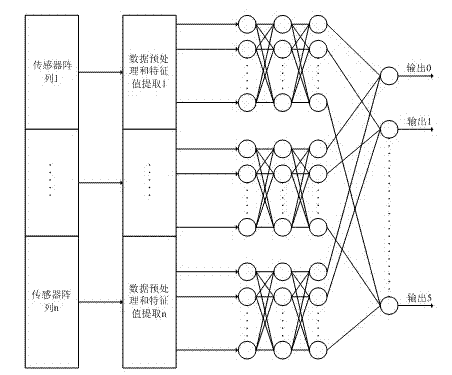

Method used

Image

Examples

Embodiment 1

[0038] Layout of detection unit: Image 6 It is the plane layout of the gas sampling point of the detected harmful gas in the mine environment. The part is 100 meters long, 50 meters wide, and 5 meters high. This area is the working surface. The circle in the figure represents the sampling of the air inlet Point, where 1 represents the sampling point of the air inlet is 1 meter from the ground, 2 represents the sampling point of the air inlet is 2 meters from the ground, and 3 represents the sampling point of the air inlet is 3 meters from the ground. There are three sampling points in the mine area. The gas sampling points of different heights are arranged at intervals. They are distributed in the working surface to reflect the distribution of harmful gases in the area. The detection unit and computer are placed in the control room.

[0039] Sampling: Since the distribution of harmful gases in the mine environment is highly discrete, and its distribution and concentration have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com