Machining file planning system and machining file generating method

A technology for processing files and planning systems, applied in general control systems, control/regulation systems, instruments, etc., to solve problems such as difficulty in using and sharing, poor readability of G-code programs, affecting the processing speed and quality of CNC systems, etc. problems, to achieve the effect of improving printing speed, saving storage space, and simple control of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

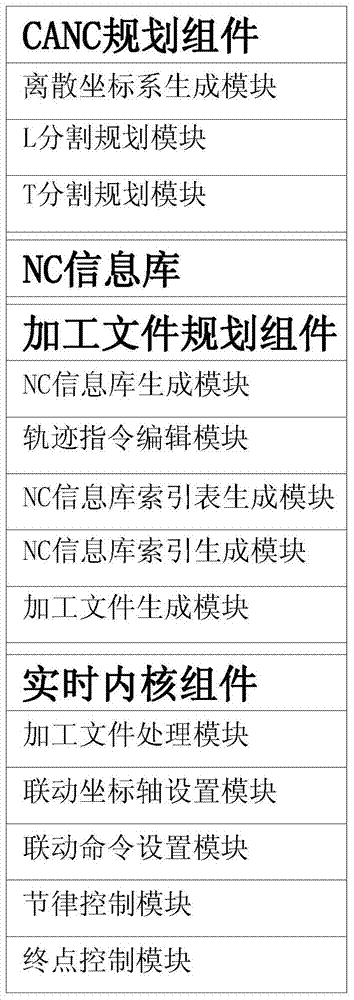

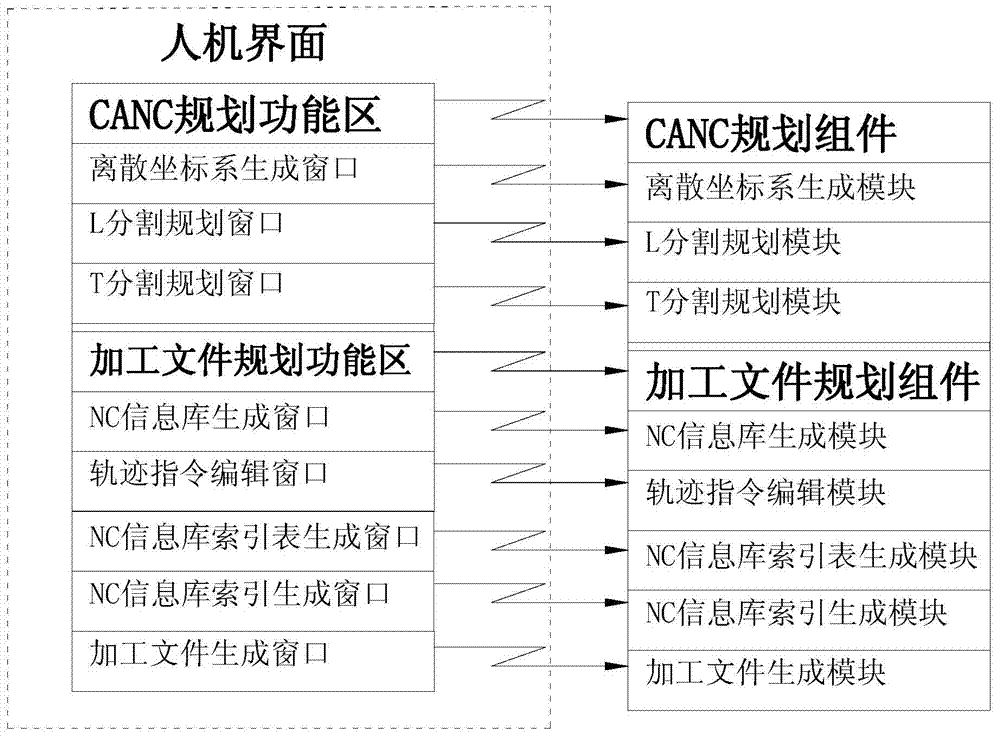

[0161] The present application takes a five-axis linkage and parallel kinematic machine (PKM) as a specific embodiment to describe the technical solution of the present application in detail.

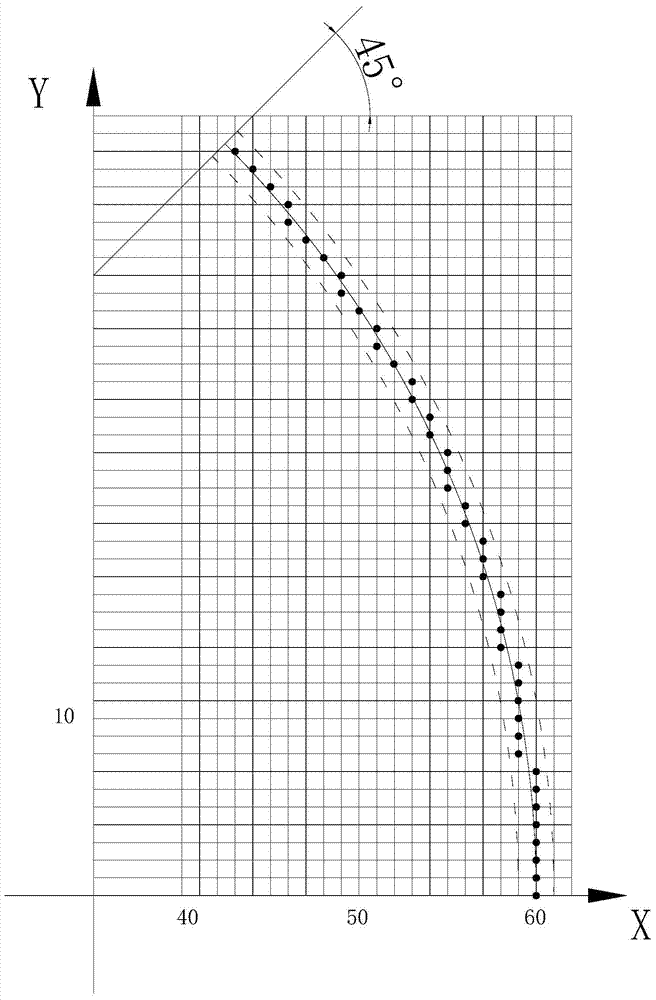

[0162] In the technical background, the present application has pointed out that the generation of the tool path curve is the most extensively researched content in the existing CNC system. The application also pointed out that no matter how complicated the mathematical calculation is, it is not a problem to generate the tool path curve for the complex motion relationship in the mechanism. The difficulty is that the feed amount of the relevant coordinate axes must be interpolated in real time in a very short time. For five-axis linkage and parallel machine tools, all the technical bottlenecks of the existing CNC system essentially originate from this.

[0163] The coordinate axes of the five-axis linkage CNC machine tool include three translation axes and two rotation axes, and the five...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com