Full-control intelligent high-power arc-free DC bus contact device

A technology of DC bus bar and contact device, which is applied in the field of medium-voltage and high-voltage high-power DC switches and high-power DC switches, which can solve the problems of non-contact switches that are susceptible to interference, and achieve the effect of avoiding thermal hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

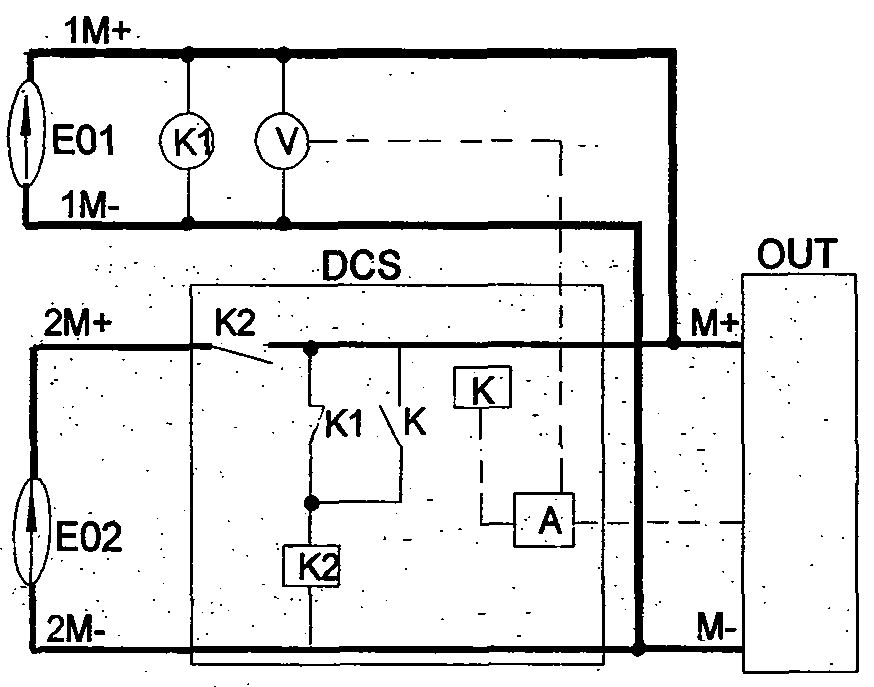

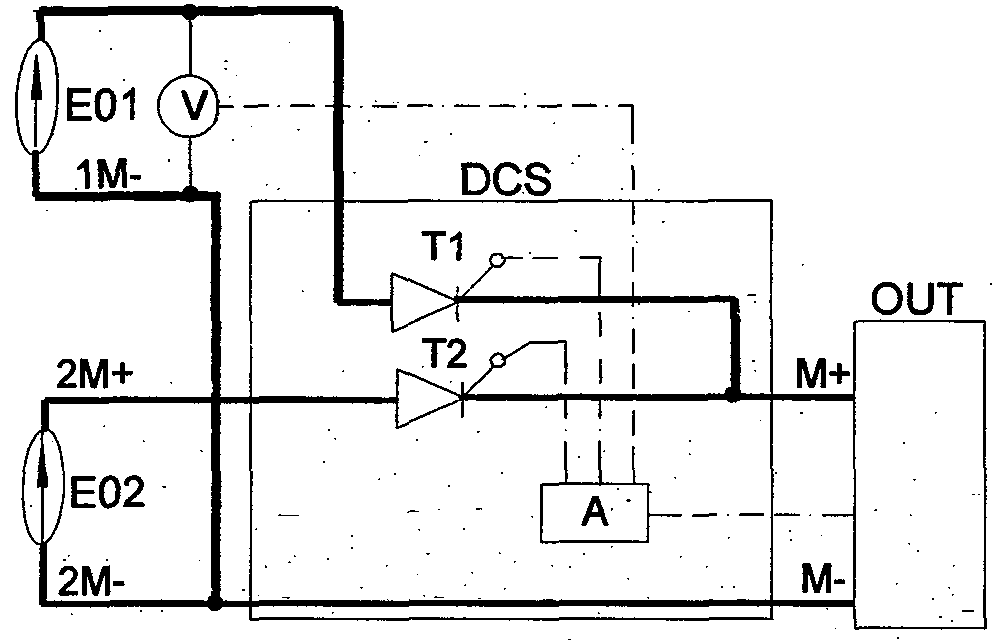

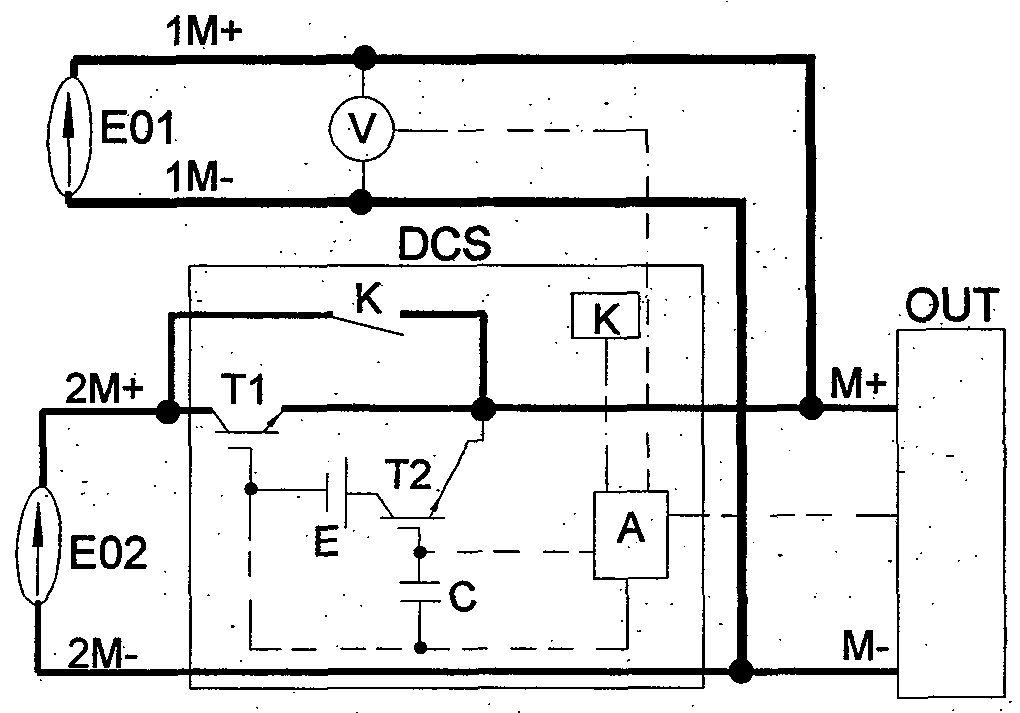

[0011] Such as image 3 As shown, the full-control intelligent high-power arc-free DC bus contact device (DCS) is composed of a controller A, a contact switch K, a non-contact main switch T1 and its anti-interference circuit. The anti-interference circuit is controlled by a non-contact A switch T2, a voltage source E and a capacitor C are formed.

[0012] The positive pole of T1 is connected to the input end of the K main contact at the same point, and then connected to the positive pole of the busbar (2M+) of the emergency DC power supply E02, and its negative pole is connected to the output end of the K main contact point and the negative pole of T2, and then connected to the output busbar The positive pole (M+), its control pole is connected to the negative pole of E and the positive pole of C, and then leads to A; the positive pole of T2 is connected to the negative pole of E, and its control pole is connected to the negative pole of C, and then leads to A; A is also connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com