Wire drawing device suitable for disassembling waste motor stator

A motor stator and waste technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of laborious operation, small pulling force, and low efficiency, and achieve fast operation speed, high work efficiency, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

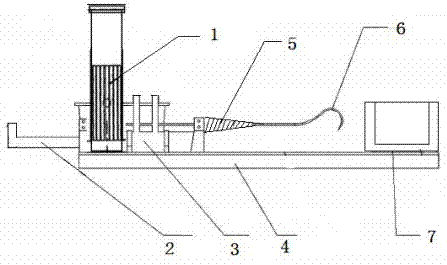

[0012] This embodiment provides a wire-drawing device suitable for dismantling the stator of a waste motor, characterized in that: the wire-drawing device suitable for dismantling a stator of a waste motor includes a drive cylinder (1), a slide rod (2), a jack ( 3), working chute (4), spring (5), wire catch hook (6), waste motor stator (7);

[0013] Among them: one side of the workbench is fixedly equipped with a drive cylinder (1) and is connected with a jack (3), and the other end is provided with a detachable fixing seat for a waste motor stator (7), and the wire grabbing device is fixed on the workbench. The thread grabbing device includes a spring (5) and a thread grabbing hook (6). The jack (3) and the connected driving cylinder (1) move on the working slideway (4) on the workbench through the slide bar (2).

[0014] The driving cylinder (1) is a driving cylinder or a hydraulic cylinder, and the driving device includes a hydraulic cylinder, an oil storage tank and a pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com