DC-DC voltage converter and conversion method

A technology of DC-DC and converters, applied in the field of DC-DC voltage converters, can solve problems such as poor performance, increased design constraints, and noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

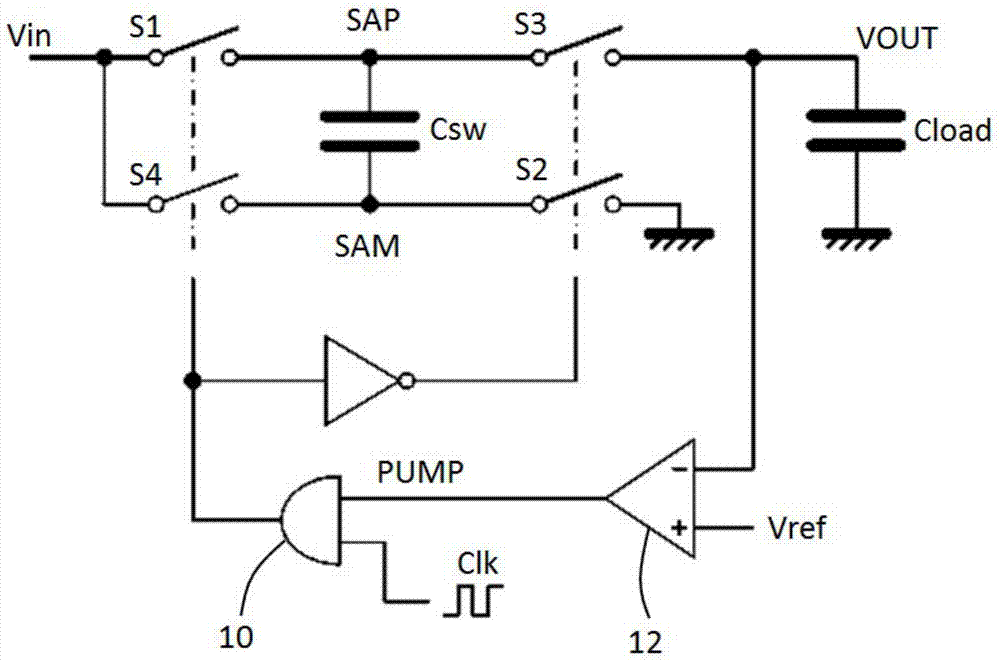

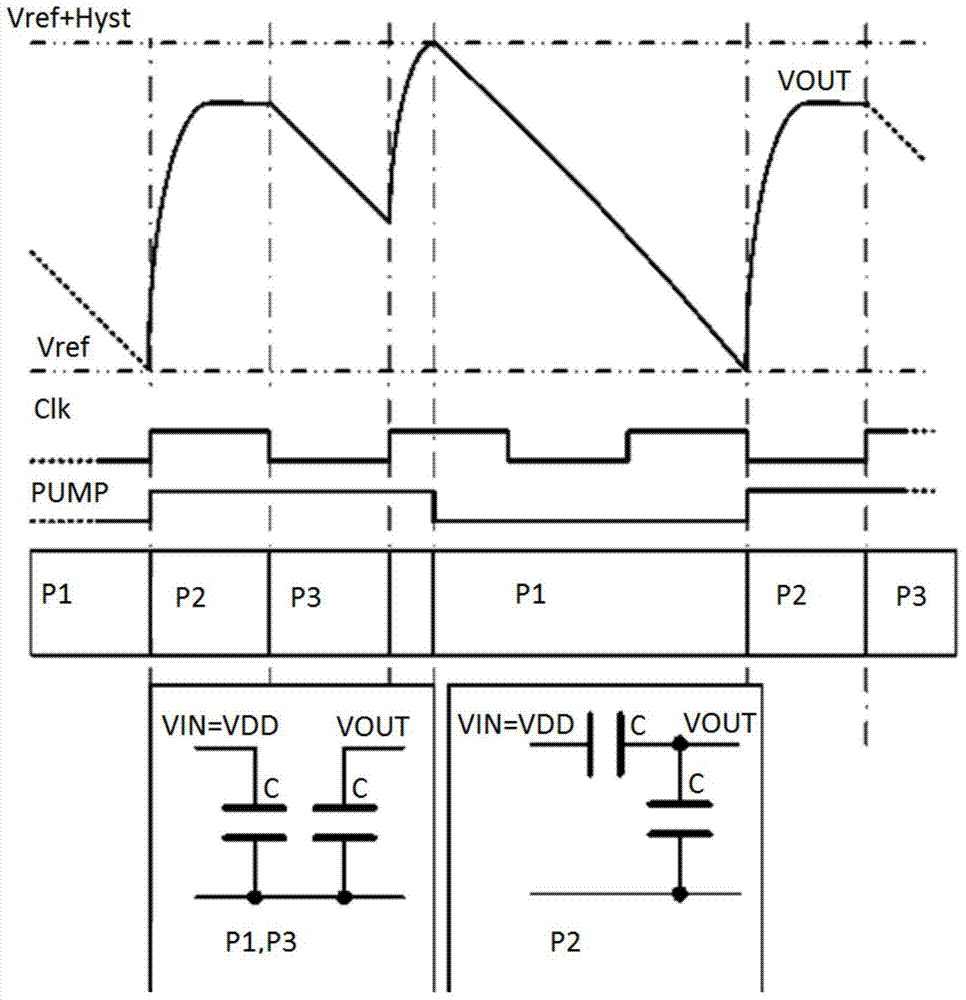

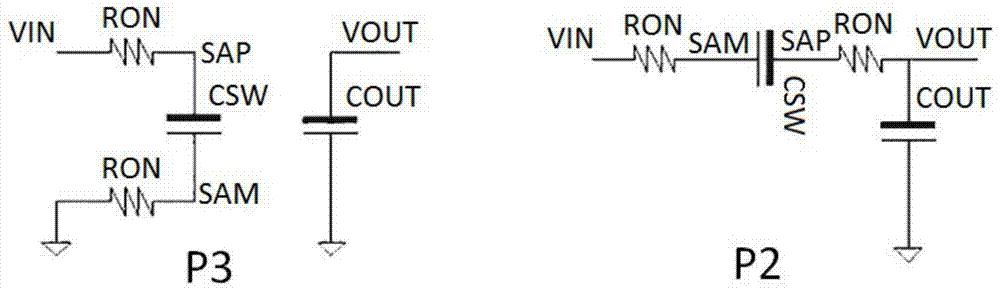

[0074] This application describes a DC-DC converter using a switched capacitor arrangement. A filter capacitor is connected between one terminal of the capacitor means and the fixed voltage line, and the calibration means are used to set or enable selection of the capacitor of the filter capacitor.

[0075] In this way, capacitors are added to the terminals of the switched capacitor arrangement. Capacitor values can be selected or adjusted to keep the current capability of the DC-DC converter within specified limits.

[0076] This adjustment or selection can be achieved in two ways:

[0077] (i) Using an external capacitor

[0078] In this case, the capacitor can be selected by the user. For the required current capability of the DC-DC converter, the DC-DC converter integrated circuit can be designed for the worst case, which usually represents the highest operating temperature. Load the DC-DC converter with the maximum load current by calibrating the setup, then adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com