Gas water heating device

A gas-fired hot water and heat exchanger technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of tank pressure and scale sensitivity, reduce scale precipitation, speed up water flow, Address the effects of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better illustrate the present invention, further description will now be made in conjunction with the embodiments and accompanying drawings.

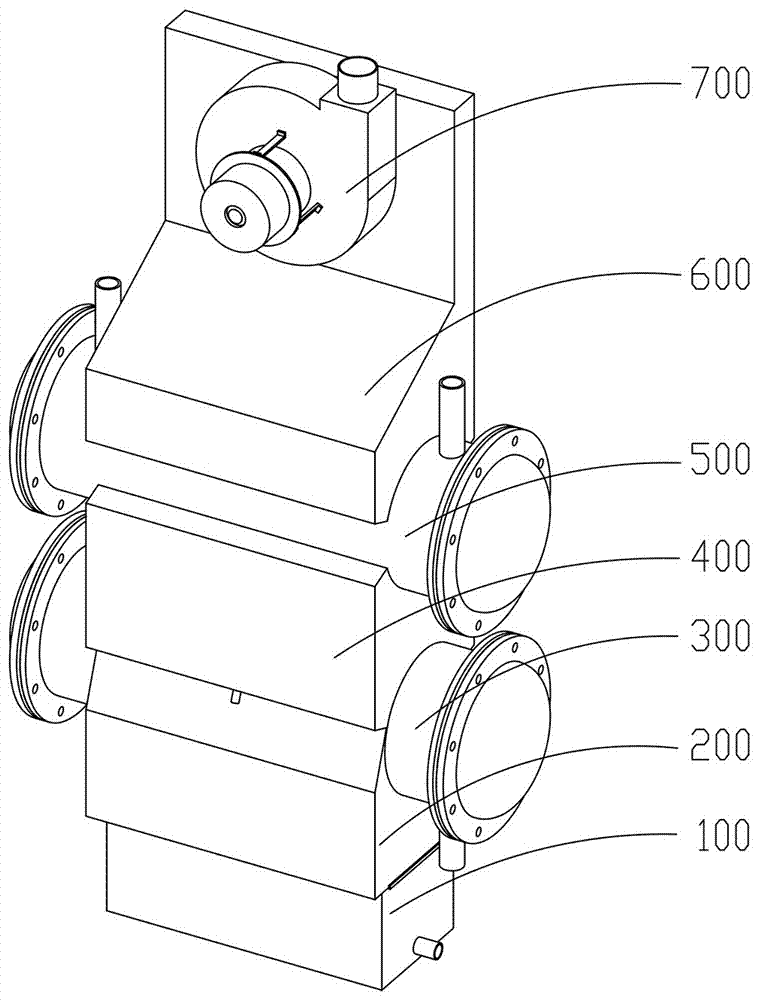

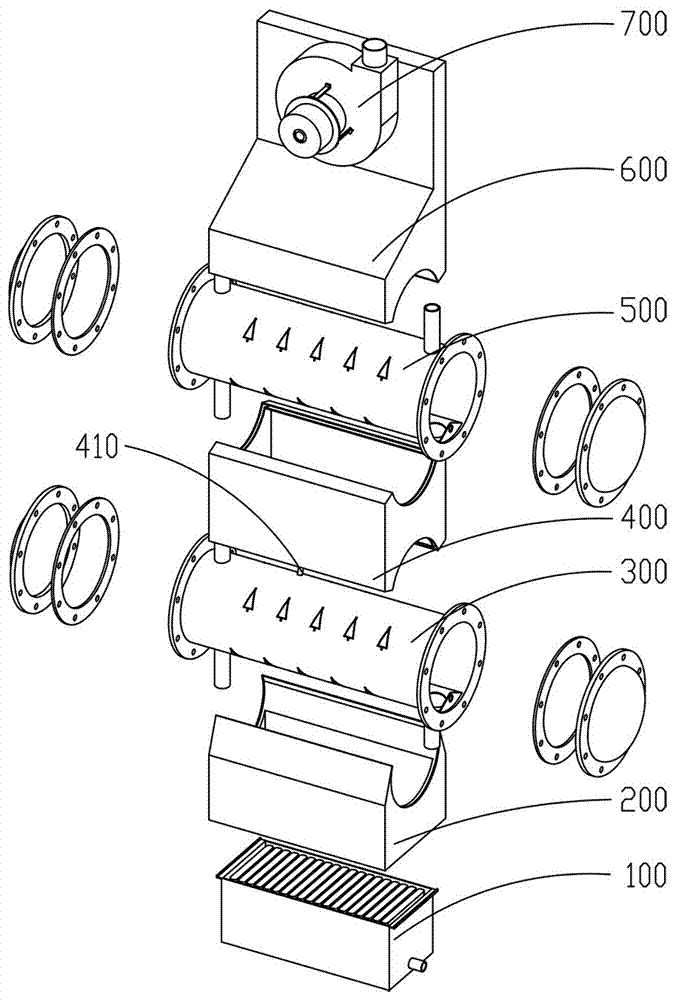

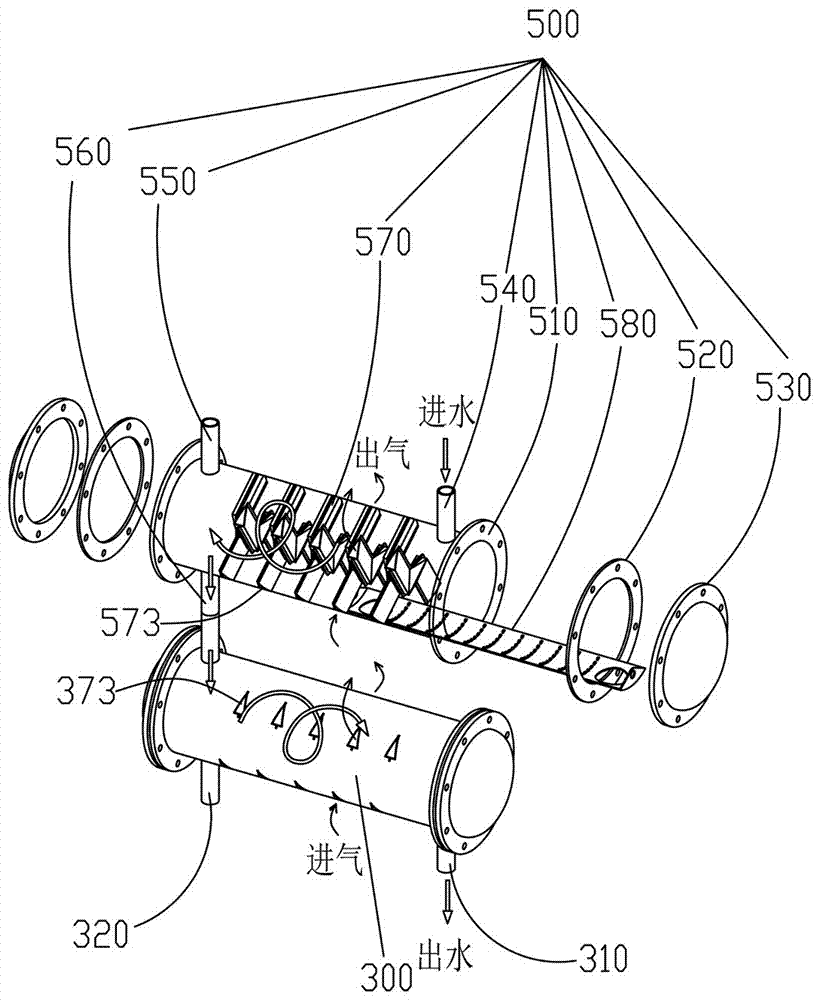

[0026] Such as Figure 1 to Figure 5 As shown, the gas water heating device includes a burner 100, a combustion chamber 200, a lower heat exchanger 300, a lower smoke collection chamber 400, an upper heat exchanger 500 and an upper smoke collection chamber 600 installed sequentially from bottom to top; The heat exchanger 500 is a tubular structure placed horizontally. Flanges 510 are respectively provided at both ends of the upper heat exchanger 500. There are sealing rings 520 and sealing covers 530 on the outside of the flanges 510. The sealing covers 530 and sealing covers at both ends of the upper heat exchanger 500 are The sealing ring 520 forms a closed pipeline space inside the upper heat exchanger 500; the top of the upper heat exchanger 500 is respectively provided with an outwardly extending water inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com