A multifunctional artificial core preparation instrument

An artificial core and multi-functional technology, which is applied in the field of artificial core production for experimental research, can solve the problems such as difficulty in meeting the requirements for use, step-by-step changes, and inability to simulate the diagenetic process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

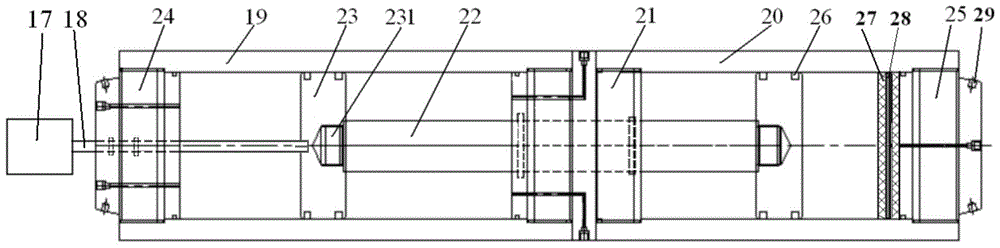

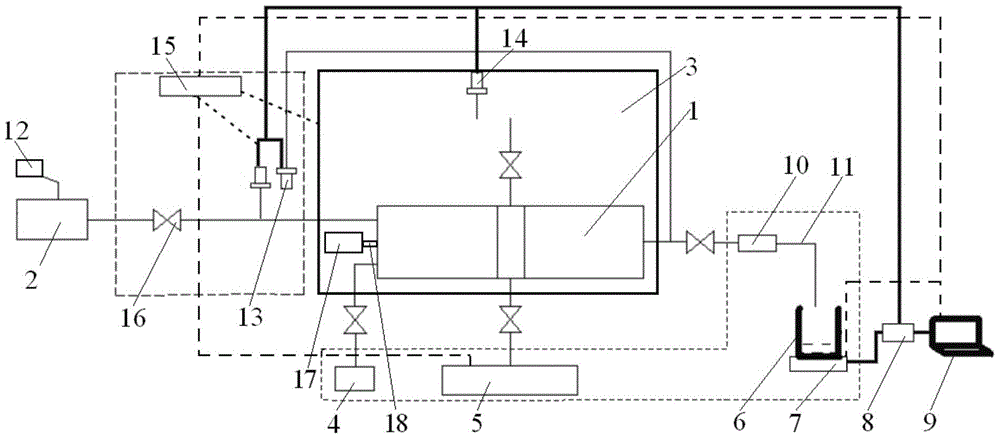

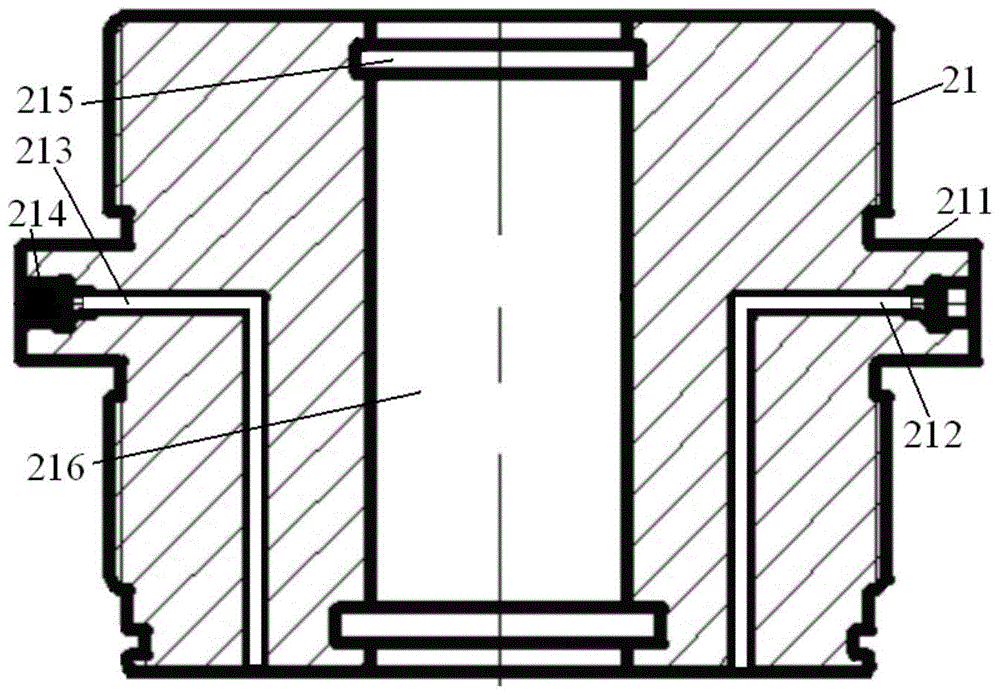

[0027] The multifunctional artificial core preparation instrument provided by the invention has a structure such as figure 2 As shown, it at least includes an intelligent control incubator 3 with a temperature-controllable temperature transmitter 14, a compaction model tube 1 located in the intelligent control incubator, a high-temperature and high-pressure pump 2 communicated with the compaction model tube, and the compaction model The structure of the cylinder is as figure 1 As shown, it includes cavity A20, cavity B19, connecting block 21, pressing rod 22, pressing cap A25, pressing cap B24 and two pistons 23, cavity A and cavity B are connected through the connecting block between them. connection, the cavity A is provided with a filter layer consisting of two layers of 1500-mesh filter screens 27 and filter paper 28 sandwiched between the two l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com