A sewing method and shaping mold of a carbon fiber box-shaped prefabricated part

A technology for shaping molds and prefabricated parts, which is applied to the sewing method of carbon fiber box-shaped prefabricated parts and the field of shaping molds and resin-based composite materials. It can solve problems such as difficulty in ensuring box-shaped prefabricated parts, poor dimensional stability, and high dimensional accuracy. Achieve the effects of ensuring dimensional accuracy and stability, easy disassembly and assembly, and high fiber volume content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

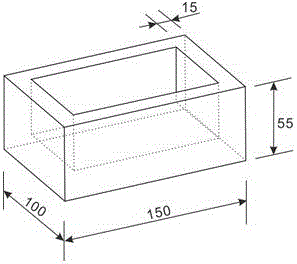

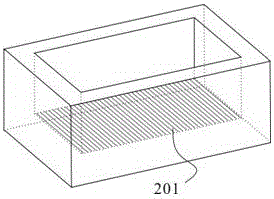

[0100] The carbon fiber rectangular box prefabricated part of 150mm * 100mm is made by adopting the sewing method of the present invention and the shaping mold, and the specific requirements are: (1) the fiber volume content is higher than 50%; (2) the thickness of the bottom of the prefabricated part and The thickness of the four side walls is 15mm; (3) The height of the side wall is 55mm; (4) The suture needle distance and line distance are 5mm; (5) The ply angle is [0°, 90°]; (6) This prefabricated Parts are used for carbon / carbon composite materials, and the performance requirements of each side wall are basically the same; (7) Seam requirements: 2 strands of T300 carbon fiber. The structural dimensions of this prefabricated part refer to figure 1 shown.

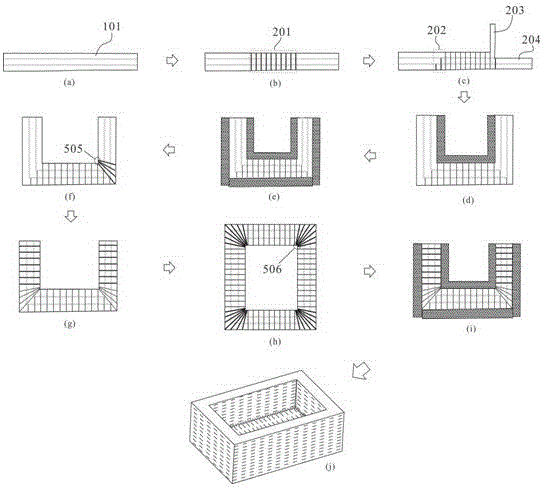

[0101] The sewing process of the carbon fiber box type prefabricated part designed by the present invention specifically comprises the following steps (see figure 2 ):

[0102] First, according to the thickness and a...

Embodiment 2

[0125] A carbon fiber rectangular box preform with a bottom size of 150 mm×100 mm is produced by using the sewing method and the shaping die described in the present invention, the bottom thickness of the preform is 15 mm, and the side wall thickness is 10 mm. The height of the side wall is 55mm, the thickness of a single layer of carbon fiber cloth is 0.33mm, and the sewing stitch and line spacing are 5mm. The ply angle is [0°,90°].

[0126] Analysis: The difference between the requirements of this box-shaped prefabricated part and that of Example 1 is that the side wall is thinner than the bottom, so the side wall needs to be removed by 5 divided by 0.33 to be 15 layers of carbon cloth. The main difference from the sewing method of the example is Two steps: sewing the side wall area of the base and the three-dimensional wrapping box-type prefabricated part in a partially penetrating manner.

[0127]Partially penetrate the sidewall area of the bottom: In this step, the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com