Upper support frame of automobile dashboard crossbeam

A technology for an automobile instrument panel and a support frame, which is applied in the field of auto parts, can solve the problems of complex structure of the upper support frame, complex overall manufacturability, increased mold cost, etc., and achieves good loading effect and stability, and the mold forming process is simple. The effect of reducing the amount of stamping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

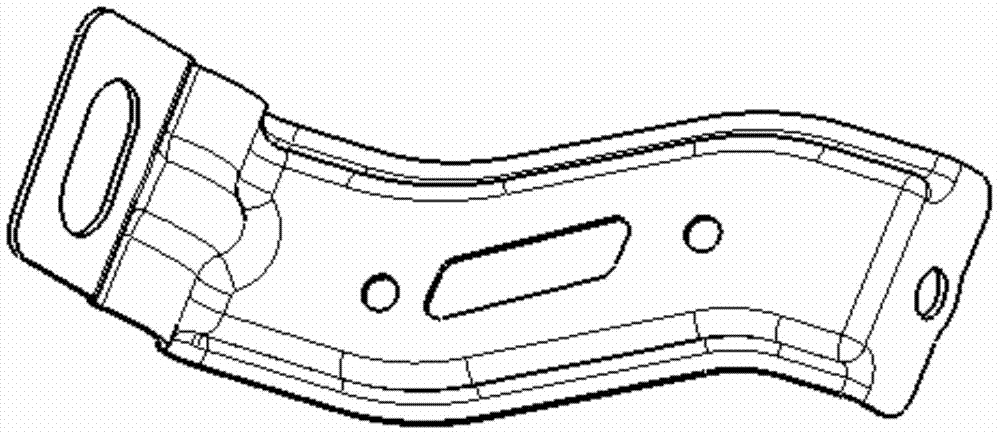

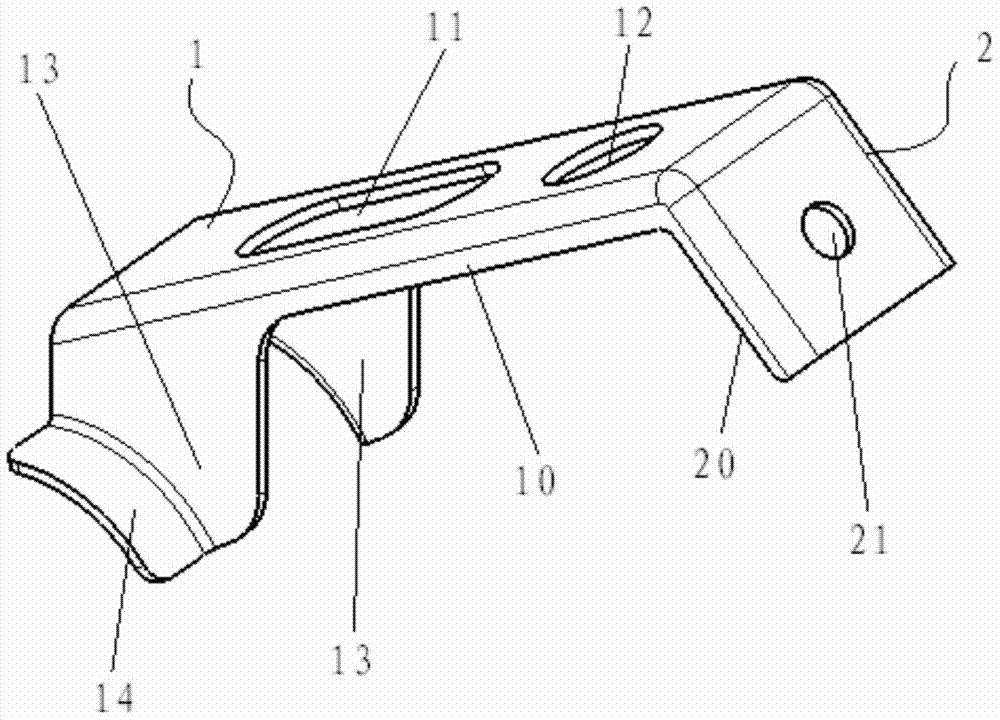

[0012] see figure 2 , the upper support frame of the automobile instrument panel crossbeam of the present invention comprises a support body 1 and a mounting plate 2 integrally stamped and formed, wherein:

[0013] The bracket body 1 is a flat plate structure and has a small section of lower flange 10 as a reinforcing rib respectively on both side edges, so that the cross section of the bracket body 1 is C-shaped; Heavy rectangular connection holes 11 and a circular connection hole 12 can reduce the weight of the airbag mounting bracket; the front two sides of the bracket body 1 respectively have a wing plate 13 extending downwards along the reinforcing rib and a pair of connecting brackets. The welding plate 14 at the front lower end of the wing plate 13, the welding plate 14 is an arc-shaped plate with the opening turned outwards, and the arc is adapted to the main pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com