An installation method of a retractable azimuth thruster

A technology of azimuth propeller and installation method, which is applied in the directions of transportation and packaging, ship parts, ships, etc., can solve the problem of inability to meet the installation of the propeller, and achieve the effect of reducing the support height of the total section, operating safety, and compressing the dock cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] A method for installing a telescopic azimuth thruster of the present invention comprises the following steps:

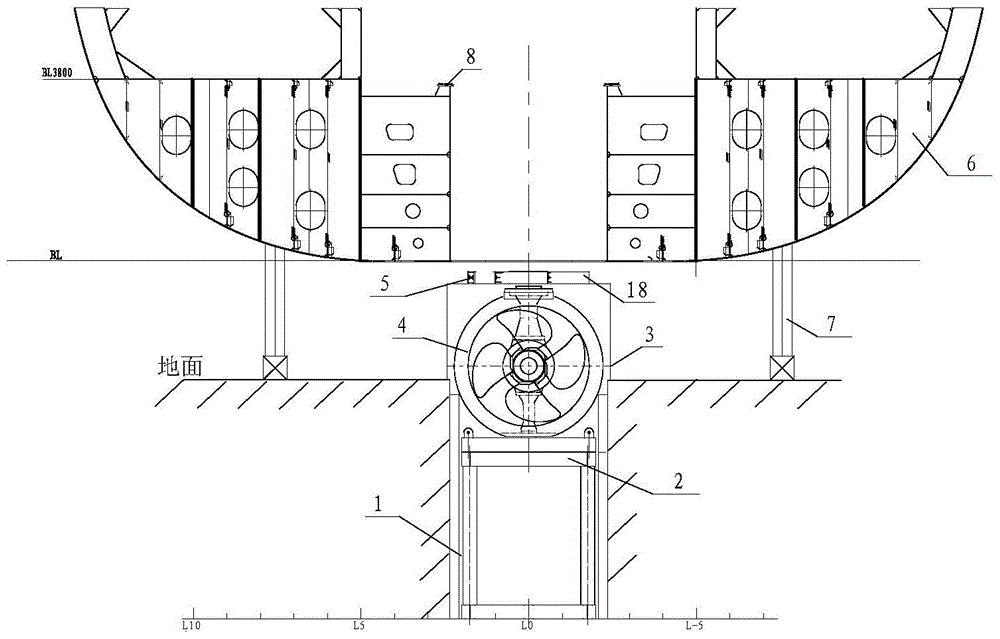

[0025] Such as figure 1 As shown, the bracket tooling 2 and the cover plate tooling 3 are designed in the pit 1 of the general group site, and then the underwater part 4 of the telescopic azimuth propeller is placed on the bracket tooling 2; the cover plate tooling 3 is placed on Above the underwater part 4 of the retractable azimuth propeller; then place the thrust beam 18 and the underwater support plate 5 on the cover plate tooling 3; then position the bottom section 6 above the pit, and fix it with a support 7, At the same time, the flatness processing of the base plane of the telescopic azimuth thruster is completed;

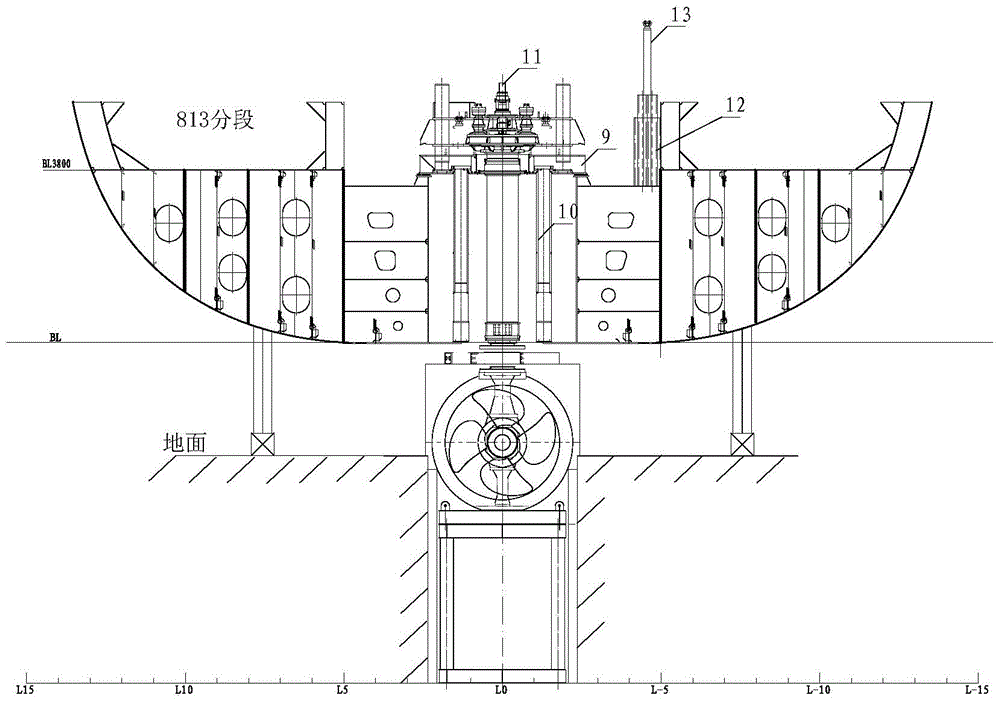

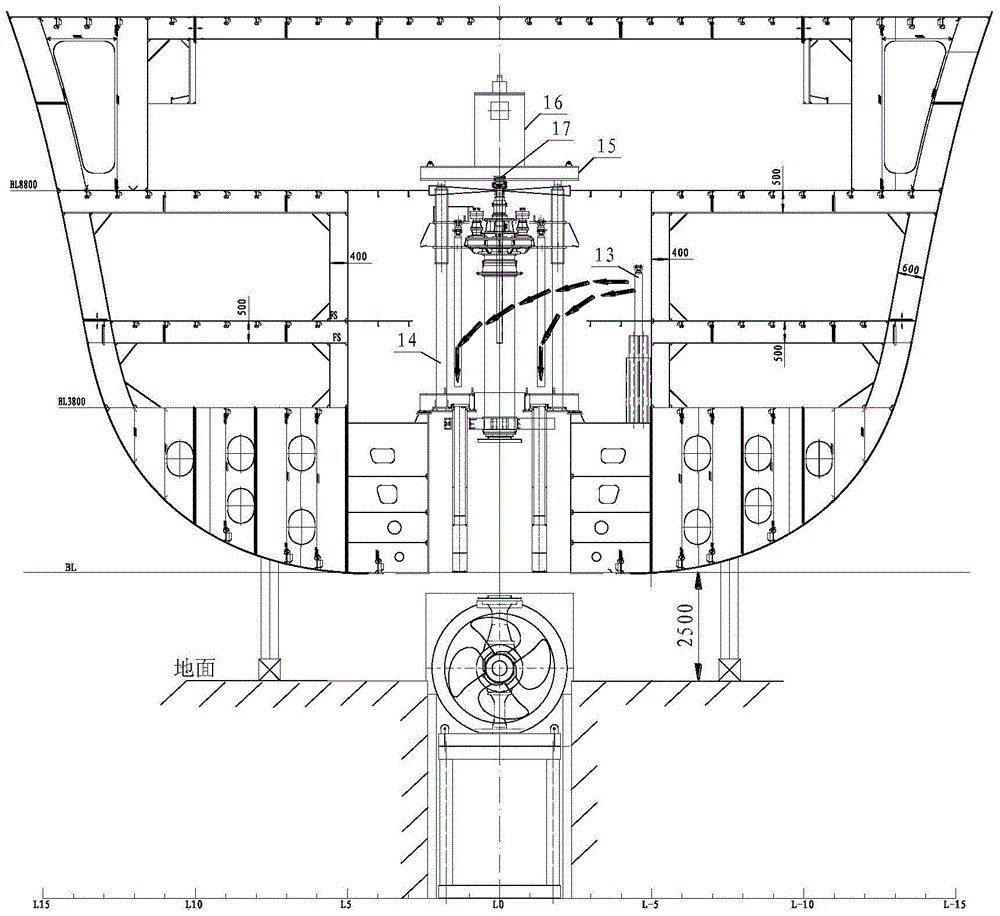

[0026] Such as figure 2 As shown, install the installation base 9, the underwater conduit 10 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com