A method for polyoxymethylene dimethyl ether adsorption, membrane separation and dehydration

A polyoxymethylene dimethyl ether, membrane separation technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as unachievable effects, low water content, and no reference value, etc., to achieve Ensure complete independent operation, improve yield, and facilitate adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

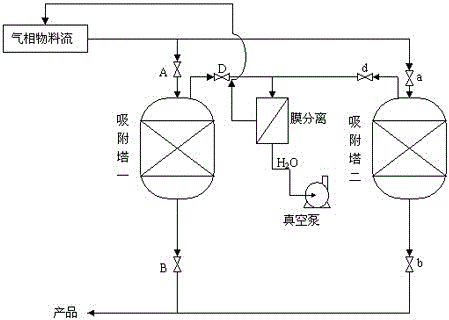

[0039] Such as figure 1 Shown, a kind of polyoxymethylene dimethyl ether adsorption, membrane separation is combined dehydration method, comprises the following steps:

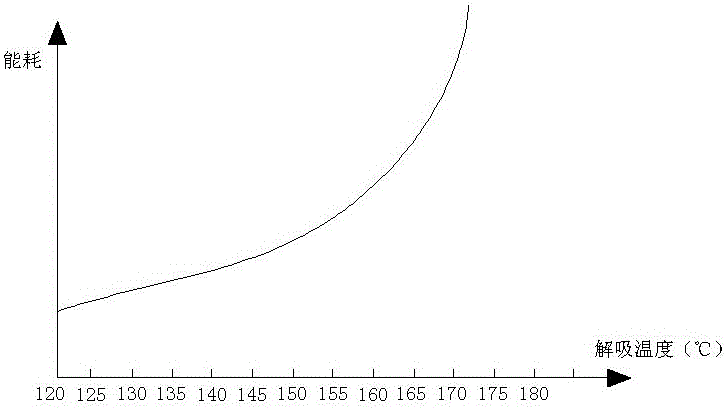

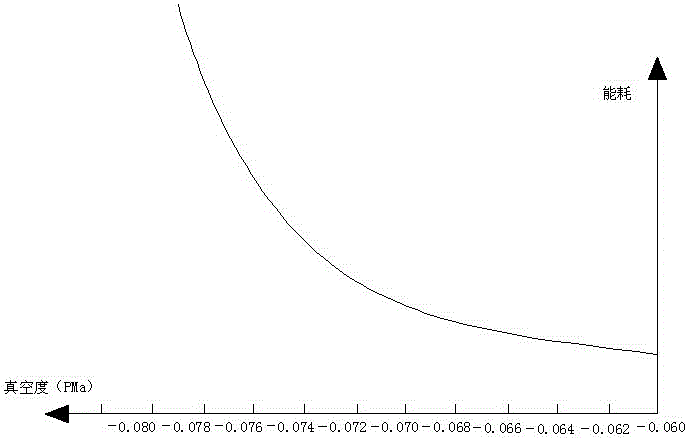

[0040] (a) The volume percentage content is respectively: 2%~10% for water, 3%~5% for methanol, 3%~5% for formaldehyde, 60%~80% for PODE2, and the rest is the gas phase material of PODE3~8 The raw material gas is sent from the top of the adsorption tower one, and the adsorption reaction is carried out in the adsorption tower one. The temperature in the tower is 120-180 degrees Celsius, and it remains constant. Moisture adsorption, the adsorbent can be one or two or more of molecular sieve, silica gel, activated alumina, resin, molecular sieve is preferred, and the unadsorbed gas is discharged from the bottom of the adsorption tower one and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com