Polypropylene structure foamed material with favorable appearance and preparation method thereof

A foaming material and polypropylene technology, applied in the field of polypropylene structural foaming material and its preparation, can solve the problems of surface breakage, large equipment cost, potential safety hazards in high-pressure gas, etc. The effect of improving high temperature strength and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Premixing of some raw materials: first, 58 parts of homopolypropylene resin, 10 parts of copolymerized polypropylene resin; 7 parts of toughening agent, 15 parts of filler, 0.1 part of crystal nucleating agent, 0.2 part of 1010 antioxidant, 168 0.2 parts of antioxidant, stir evenly in a high-speed mixer;

[0040] (2) Preparation of polypropylene modified material for foaming: Add the mixed material pellets from the main feeding port of the twin-screw extruder, add 8 parts of glass fibers from the side feeding port, and perform melt blending and extrusion Granulating to obtain a polypropylene modified material for foaming;

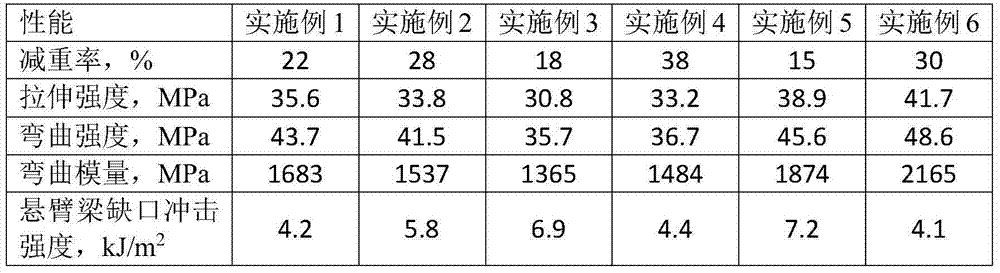

[0041] (3) Injection foaming: Mix 1.5 parts of foaming agent masterbatch and 98.5 parts of polypropylene modified material for foaming obtained in step (2) in a high-speed mixer; then put them into an injection molding machine for injection foaming , to obtain structural foamed polypropylene material, the performance test results are shown in Ta...

Embodiment 2

[0043] (1) Premixing of some raw materials: first, 39.2 parts of homopolypropylene resin, 28 parts of copolymerized polypropylene resin; 5 parts of toughening agent, 20 parts of filler, 0.2 part of crystal nucleating agent, 0.3 part of 1010 antioxidant, 168 0.3 parts of antioxidant, stirred evenly in a high-speed mixer;

[0044] (2) Preparation of polypropylene modified material for foaming: add the mixed material pellets from the main feed port of the twin-screw extruder, add 5 parts of glass fiber from the side feed port, and perform melt blending and extrusion Granulating to obtain a polypropylene modified material for foaming;

[0045] (3) Injection foaming: Mix 2 parts of foaming agent masterbatch and 98 parts of polypropylene modified material for foaming obtained in step (2) in a high-speed mixer; then put them into an injection molding machine for injection foaming , to obtain structural foamed polypropylene material, the performance test results are shown in Table 1....

Embodiment 3

[0047] (1) Premixing of some raw materials: first, 40 parts of homopolypropylene resin, 40 parts of copolymerized polypropylene resin; 3 parts of toughening agent, 10 parts of filler, 0.2 part of crystal nucleating agent, 0.3 part of 1010 antioxidant, 168 0.3 parts of antioxidant, stirred evenly in a high-speed mixer;

[0048] (2) Preparation of polypropylene modified material for foaming: add the mixed material pellets from the main feed port of the twin-screw extruder, add 5 parts of glass fiber from the side feed port, and perform melt blending and extrusion Granulating to obtain a polypropylene modified material for foaming;

[0049] (3) Injection foaming: Mix 1.2 parts of foaming agent masterbatch and 98.8 parts of polypropylene modified material for foaming obtained in step (2) in a high-speed mixer; then put them into an injection molding machine for injection foaming , to obtain structural foamed polypropylene material, the performance test results are shown in Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com