Refined heavy-hydrocarbon removal system for recovering LNG/LPG/NGL from petroleum associated gas

A technology for petroleum associated gas and associated gas, which is used in the petroleum industry, recovery of liquid hydrocarbon mixtures, and gas fuels. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

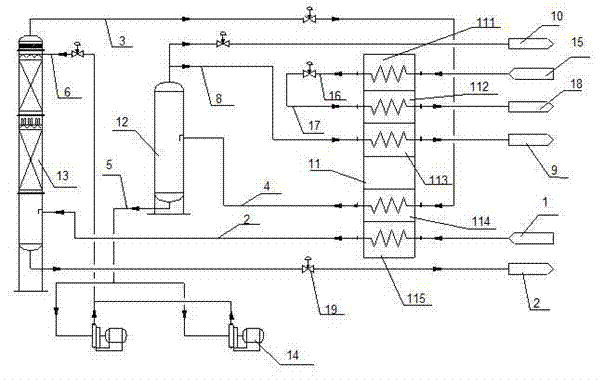

[0022] Such as figure 1 As shown, a heavy hydrocarbon refining system for recovering LNG / LPG / NGL from petroleum associated gas includes raw material associated gas inlet pipeline 1, LPG cold box 11, low temperature separator 12, and heavy hydrocarbon refining absorption tower 13. The interior of the LPG cold box 11 is divided into five independent parts from top to bottom: the upper box 111, the upper middle box 112, the middle box 113, the lower middle box 114, and the lower box 115. The gas pipeline 1 is connected to the inlet of the lower box 115, the outlet of the lower box 115 is connected to the lower inlet of the absorption tower 13 for refining and removing heavy hydrocarbons through the primary cooling associated gas pipeline 2, and the bottom of the absorption tower 13 for removing heavy hydrocarbons is The outlet is connected with the liquid phase pipeline 7 at the bottom of the tower, the outlet at the top of the absorption tower 13 is connected with the inlet of t...

Embodiment 2

[0026] On the basis of Example 1, such as figure 1 As shown, the inlet of the upper tank 111 is connected with a normal temperature primary refrigerant pipeline 15, the outlet of the upper tank 111 is connected with a low temperature primary refrigerant pipeline 16, and the inlet of the upper and middle tank 112 is connected with a low temperature The low-pressure first-stage refrigerant pipeline 17 and the outlet of the upper and middle tanks 112 are connected with a normal temperature and low-pressure first-stage refrigerant pipeline 18, and the low-temperature and low-pressure first-stage refrigerant pipeline 16 is connected to the low-temperature and low-pressure first-stage refrigerant pipeline 17. The normal temperature first-stage refrigerant enters the upper box 111 of the LPG cold box 11 through the normal temperature first-stage refrigerant pipeline 15, and the cooled low-temperature first-stage refrigerant passes through the regulating valve 19 on the low-temperature...

Embodiment 3

[0028] On the basis of Example 1, in order that the liquid separated by the low temperature separator 12 can quickly enter the upper part of the refined heavy hydrocarbon packed absorption tower 13, so the separated low temperature condensate absorbent pipeline 5 is respectively connected in parallel with two Absorbent booster pump 14, two absorbent booster pumps 14 simultaneously pump the liquid-phase low-temperature separation condensate to the packed absorption tower 13 for fine removal of heavy hydrocarbons, and the liquid-phase low-temperature separation The condensate flow rate is relatively large, and the reverse contact surface with the upward airflow in the tower is relatively large, so there will be more heavy hydrocarbons in the absorption airflow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com