Production technology of low-cold-point oleic acid

A production process, oleic acid technology, applied in the field of low freezing point oleic acid production process, can solve the problems of oleic acid difficulties, high freezing point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

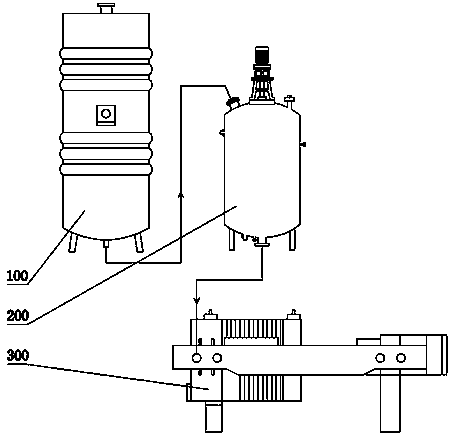

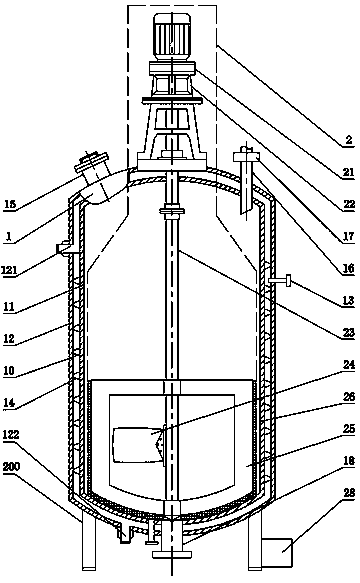

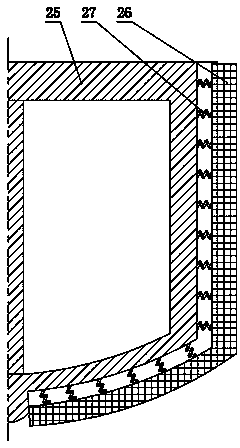

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: a kind of production technology of low freezing point oleic acid, comprises the steps:

[0019] A. Pump the industrial oleic acid into the heating tank, heat the material in the heating tank to 65°C and keep it for 50 minutes, then send the heated industrial oleic acid into the freezing crystallization tank;

[0020] B. Stir the materials in the frozen crystallization kettle at a speed of 20 rpm, and feed water at 40°C into the jacket of the frozen crystallization kettle to cool down the industrial oleic acid for 180 minutes. Cool down to 45°C and maintain this temperature for 70 minutes;

[0021] C. Reduce the stirring speed of the freezing and crystallization kettle, the rotating speed is 10 rpm, feed water at 30-35°C into the jacket of the freezing crystallization kettle, and cool down the materials in the kettle for 150 minutes, and put the materials in the kettle Cool down to 25°C and maintain this temperature for 40 minutes;

[0022] D. Stir the ma...

Embodiment 2

[0025] Embodiment 2: a kind of production technology of low freezing point oleic acid, comprises the steps:

[0026] A. Pump the industrial oleic acid into the heating tank, heat the material in the heating tank to 67°C for 40 minutes, and then send the heated industrial oleic acid into the freezing crystallization tank;

[0027] B. Stir the materials in the frozen crystallization kettle at a speed of 25 rpm, and feed water at 45°C into the jacket of the frozen crystallization kettle to cool down the industrial oleic acid for 165 minutes, and the materials in the kettle Cool down to 47°C and maintain this temperature for 60 minutes;

[0028] C. Reduce the stirring speed of the frozen crystallization kettle, the rotating speed is 10 rev / min, feed water at 33°C into the jacket of the frozen crystallization kettle, and cool the materials in the kettle for 135 minutes, and cool the materials in the kettle to 27°C, and maintain this temperature for 30 minutes;

[0029] D. Stir th...

Embodiment 3

[0032] Embodiment 3: a kind of production technology of low freezing point oleic acid, comprises the steps:

[0033] A. Pump the industrial oleic acid into the heating tank, heat the material in the heating tank to 70°C for 30 minutes, and then send the heated industrial oleic acid into the freezing crystallization tank;

[0034] B. Stir the materials in the frozen crystallization kettle at a speed of 30 rpm, and feed water at 40-50°C into the jacket of the frozen crystallization kettle to cool down the industrial oleic acid for 150 minutes. Cool the material inside to 50°C and maintain this temperature for 50 minutes;

[0035] C. Reduce the stirring speed of the frozen crystallization kettle, the rotating speed is 15 rev / min, feed water at 35°C into the jacket of the frozen crystallization kettle, and cool the materials in the kettle for 120 minutes, and cool the materials in the kettle to 30°C, and maintain this temperature for 20 minutes;

[0036] D. Stir the materials in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com