Fixing device and application thereof

A technology of fixing devices and components, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as inability to heat the shell, loss of control of the heating temperature, gap between the electric heating plate and the shell, etc., to achieve simple structure and ensure effectiveness , The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

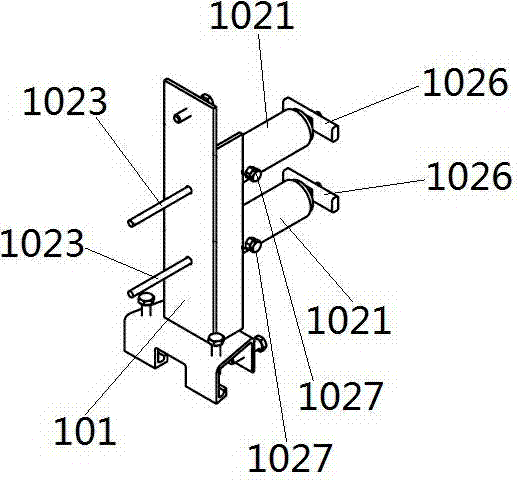

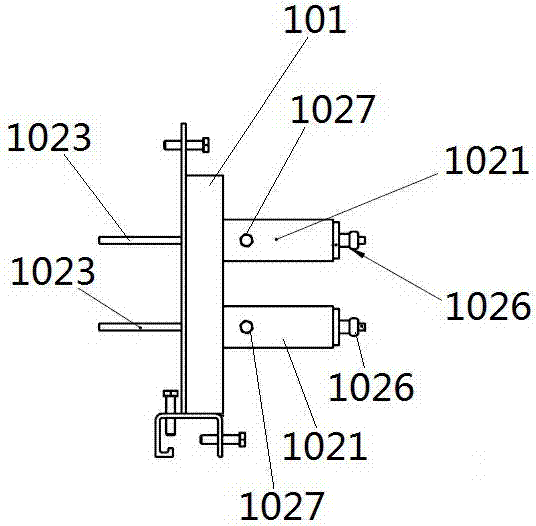

[0031] like figure 1 , figure 2 and combine Image 6 , Figure 7 As shown, a fixing device 100 is used to fix the electric heating plate 200 during the heat treatment of the annular seam of the nuclear power steam generator. The inner sleeve 400 is connected; several pushing components 102, the pushing components 102 pass through the support plate component 101, and press the electric heating plate 200, so as to reduce the gap between the electric heating plate 200 and the position to be heat treated .

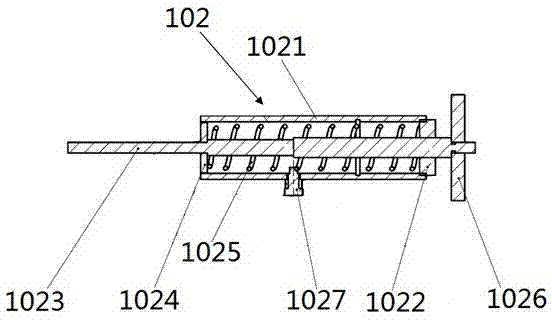

[0032] like image 3 As shown, the pushing assembly 102 includes: a sleeve 1021, one end of which is connected to the support plate assembly 101; an adjusting cover 1022, arranged on the other end of the sleeve 1021; a pushing shaft 1023, the pushing shaft 1023 comprising The first part, the second part, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com