Low-welding-crack-sensitivity high-strength seamless steel tube and manufacturing method thereof

A technology of low welding cracks and seamless steel pipes, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems such as the unspecified requirements for the flow of water in the inner shaft, and achieve the effect of good tempering stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

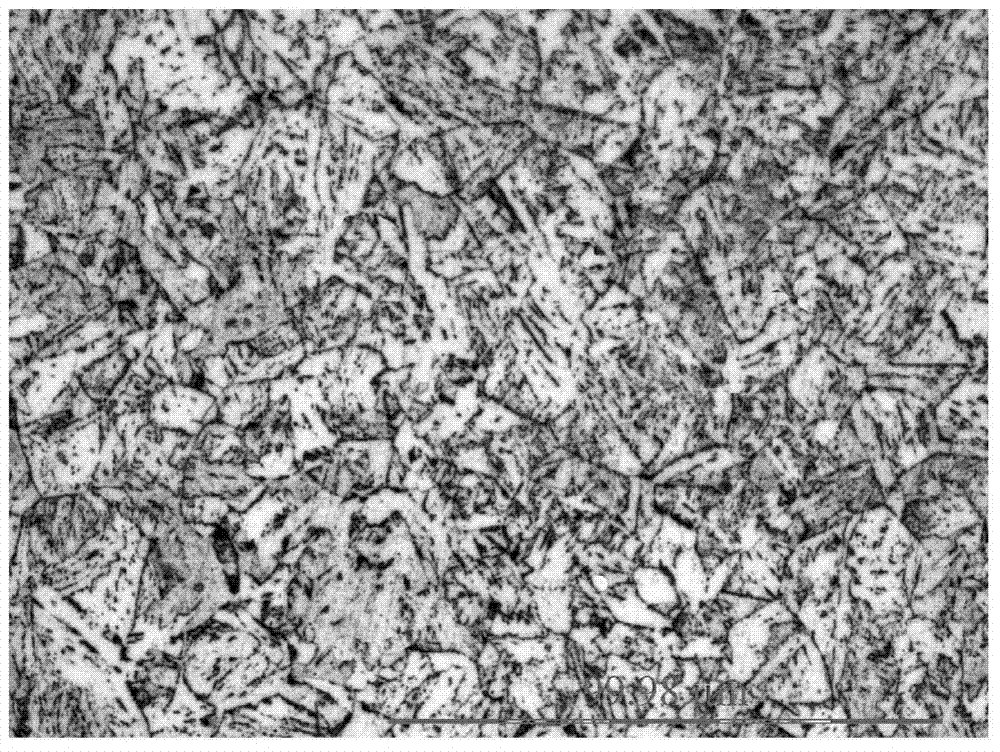

Image

Examples

Embodiment 1

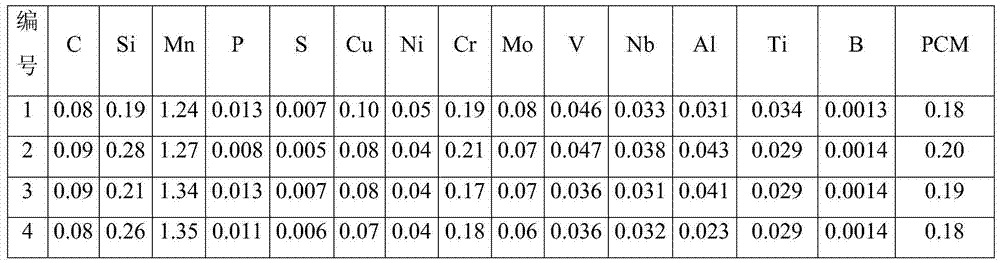

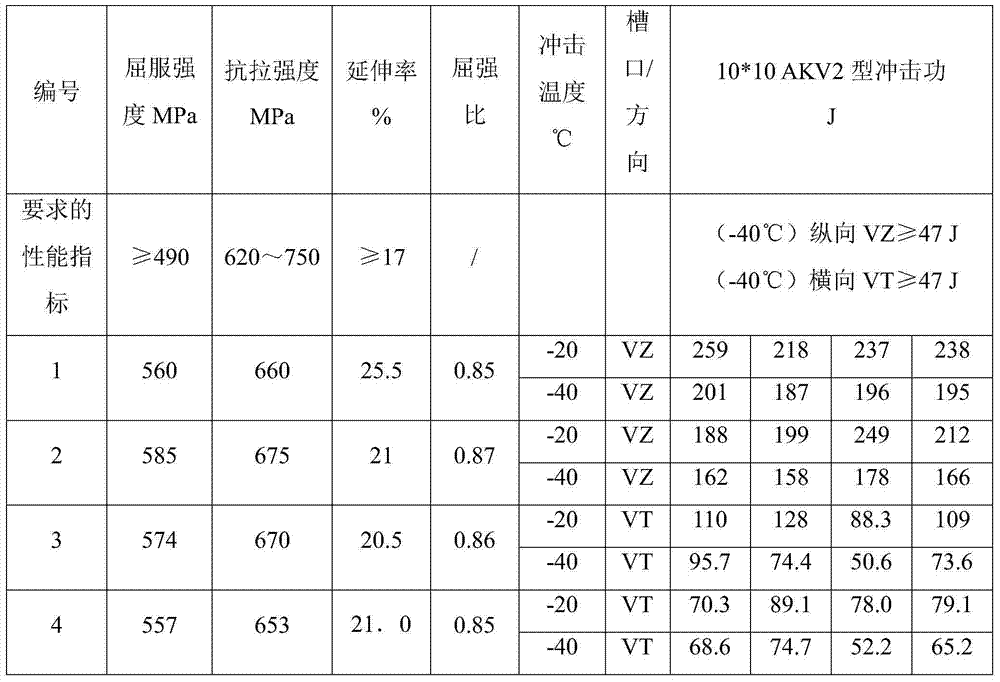

[0048] The components in Table 1 and the following process were used to produce high-strength seamless steel pipes with low welding crack sensitivity.

[0049] Table 1 Chemical composition (wt%)

[0050]

[0051] The balance is Fe and unavoidable impurities.

[0052] Production process line:

[0053] Electric Furnace→LF Furnace→VD Vacuum Treatment→ Die casting slab or 350 continuous casting slab → heating in annular furnace → piercing → rolling by rolling mill → inspection → heat treatment (quenching + tempering) → straightening → super detection → inspection → packaging.

[0054] Among them, the basic requirements for rolling:

[0055] Before starting rolling, carefully check the surface quality of deformation tools such as rolls, guide discs, plugs, and mandrels, and strengthen the lubrication of mandrels. Avoid defects such as scarring and pitting on the surface of the steel pipe. During rolling, the heating temperature of the annular furnace is 1230-1270°C, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com