Control method of automatic additive adding

A control method and automatic feeding technology, applied to the control device of washing machines, other washing machines, washing devices, etc., can solve the problems of complex structure and high cost, and achieve the effects of reducing environmental pollution, accurate control, and improving washing and rinsing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

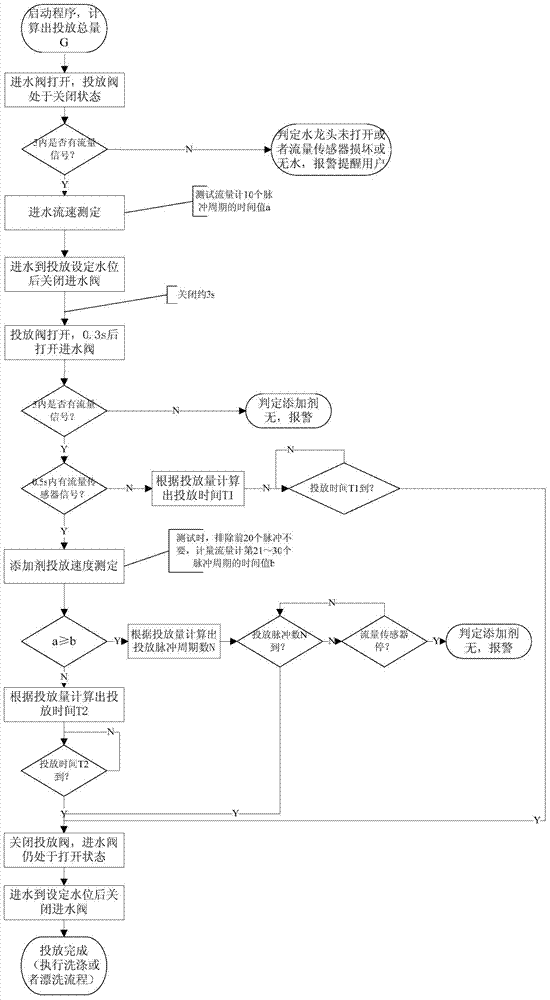

[0057] Such as figure 1 As shown, when adding liquid detergent during the laundry process, the steps are as follows:

[0058] After the washing program is started, the washing machine controller judges and calculates the total amount of detergent G required based on the sensing of the weight of the laundry, the sensing of the dirtiness of the clothes, and the sensing of the hardness of the water, and stores the value of G in the calculation inside the device.

[0059] Open the water inlet valve to enter the water. At this time, the detergent injection control valve is in the closed state, and the water flow is divided into two paths, one path is directly injected into the washing tub (tub), and the other path is injected into the washing tub after passing through the flow sensor. During water intake, first check whether there is a signal output from the flow sensor. Generally, if there is a signal output within 3s, it means that the water intake is normal; Open and the flow ...

Embodiment 2

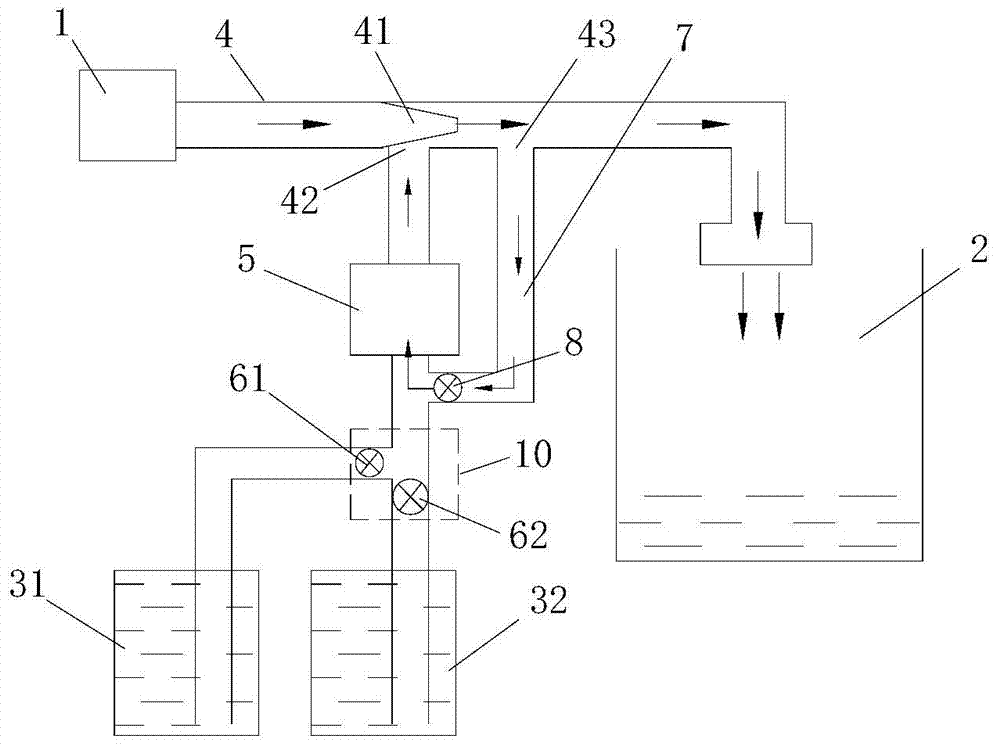

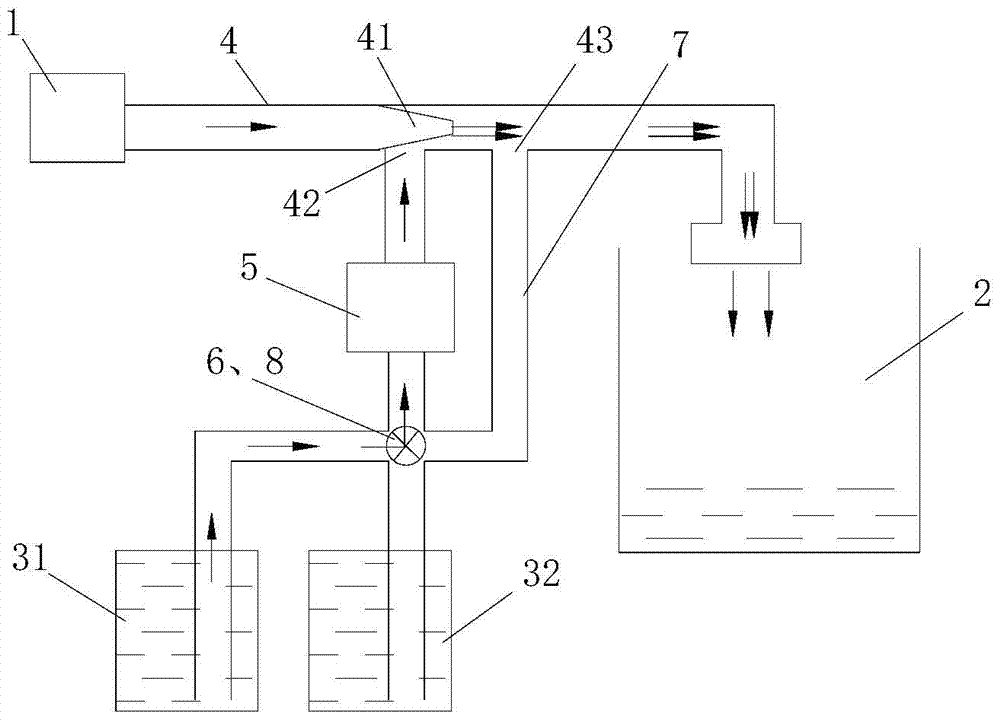

[0073] Such as figure 2 , image 3 As shown, the washing machine according to the present invention includes a water inlet valve 1, a washing tub 2 and at least one container 3 for holding additives, and a washing water inlet channel 4 between the water inlet valve 1 and the washing tub 2 is provided with a The Venturi tube 41 that can generate negative pressure through water flow, and the corresponding negative pressure area is provided with a suction port 42 that communicates with the container 3 and utilizes negative pressure to extract additives into the washing water inlet waterway, and the suction port 42 is connected to the container 3 A metering device 5 for detecting the dosage of additives and an additive control valve 6 for controlling the connection between the metering device 5 and the container 3 are provided between them.

[0074] Further, the washing machine according to the present invention also includes a washing water channel 7 of the water inlet cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com