High cutting slope anchor rope space framework supporting and retaining structure

A support structure and space technology, which is applied in the field of anchor cable space frame support structures on high-cut slopes, can solve problems such as casualties, deformation and damage of high-cut slopes, and engineering construction losses, and achieve improved stability and safety. Strong body thrust ability and the effect of reducing the cutting slope area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

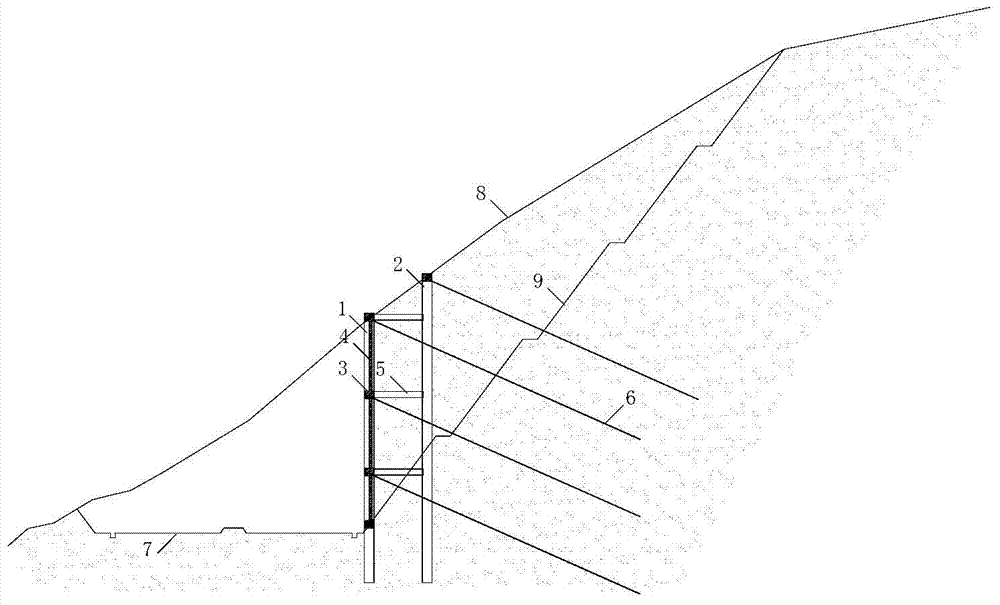

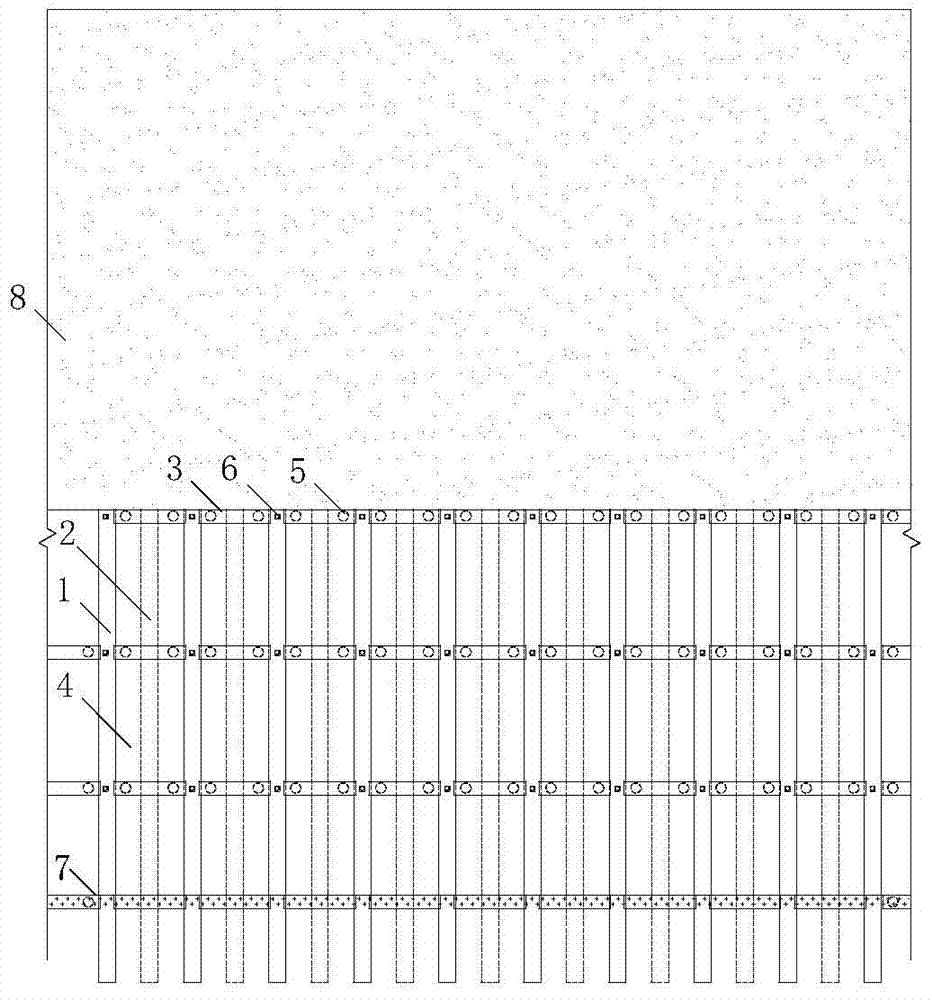

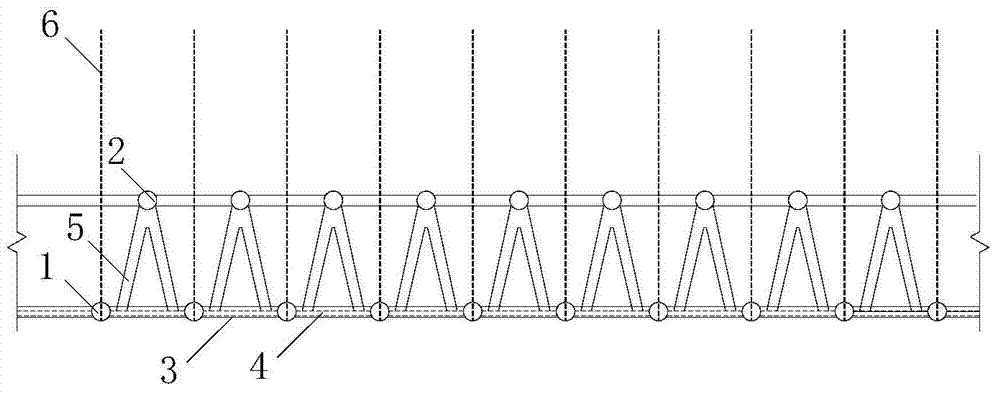

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 left view of image 3 for figure 1 bottom view.

[0021] As shown in the figure: the high-cut slope anchor cable space frame support structure of this embodiment includes the anti-slide row pile formed by cast-in-situ concrete and the retaining wall 4 poured on the anti-slide row pile, and the anti-slide row pile Horizontal and vertical staggered connections form a space frame structure; more than one row of space support structures are formed by interconnected cast-in-place reinforced concrete anti-slide piles, and combined with reinforced concrete retaining walls 4 to form a large structural rigidity, and The retaining wall 4 can further improve the lateral resistance of the retaining structure, and can also be used as a transitional link structure of the frame structure to improve the reliability of the retaining structure. The retaining structure with better soil retai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com