Natural gas pipe temperature regulation system with automatic temperature control functional module

A natural gas pipeline and functional module technology, which is applied in the field of natural gas pipeline temperature regulation system, can solve the problems of no stable sensor to automatically control temperature and heat, waste time and physical strength, etc., to expand the scope of temperature application and improve The effect of precision and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

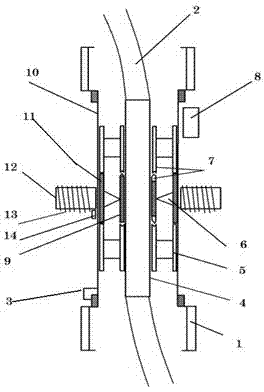

[0012] like figure 1 As shown, a natural gas pipeline temperature adjustment system with automatic temperature control function module belongs to the technical field of automatic pipeline fluid temperature control systems with automatic heating and cooling functions, including an automatic temperature control group and a pipeline equipment adjustment group. The temperature control group is composed of a temperature sensing probe 3, a temperature exchanger 10, a temperature isolating push-pull rod 7 and a valve actuator 6. The temperature sensing probe 3 is fixed on the inner wall of the middle of the pipeline and cooperates with the temperature exchanger 10. Function, the temperature-insulating push-pull rod 7 is arranged on one side of the inner wall of the pipe, and is movably connected by pushing and pulling a corresponding group of buckle structures. , the liq...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap