A double-cavity liquid film miniature liquid burner and its combustion method

A micro liquid and burner technology, applied in liquid fuel burners, combustion methods, burners, etc., can solve the problems of insufficient fuel combustion, low combustion efficiency, easy flame quenching, etc., to improve combustion efficiency and reduce heat dissipation. loss, the effect of increasing the evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

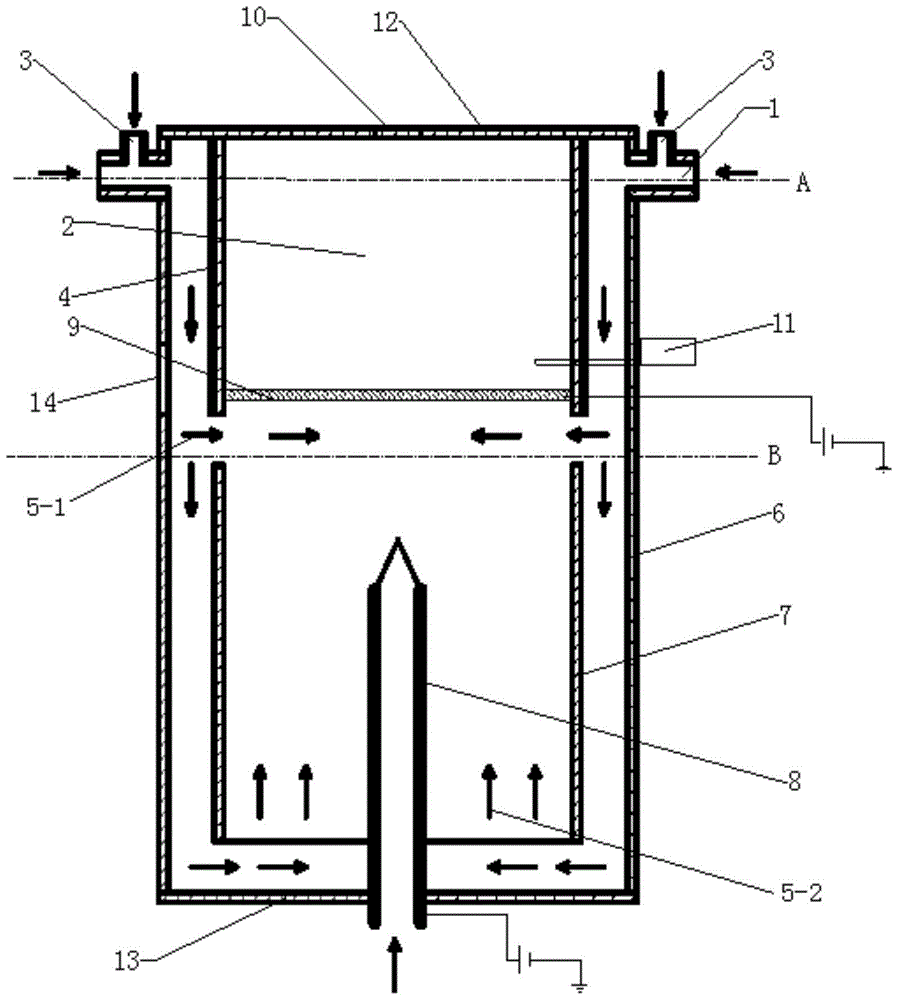

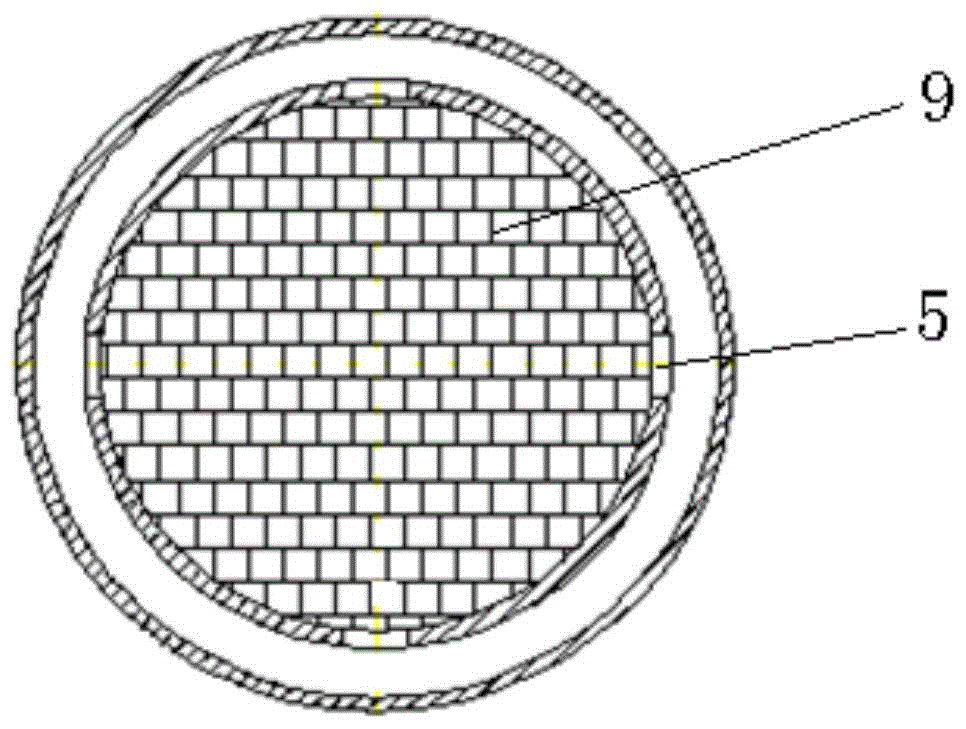

[0035] like Figures 1 to 3 shown. A double-cavity liquid film miniature liquid burner of the present invention comprises a combustion cylinder, a fuel nozzle 8 arranged at the bottom of the combustion cylinder, and an igniter 11 for igniting the fuel in the combustion cylinder;

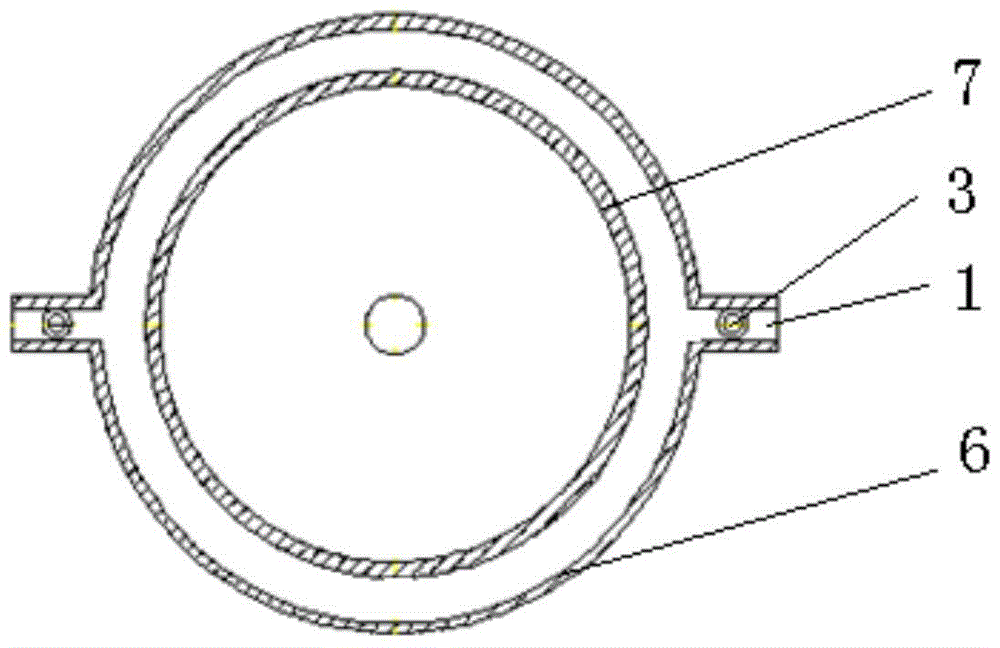

[0036] The combustion cylinder is divided into an outer cylinder 6 and an inner cylinder 7, the inner cylinder 7 is placed in the outer cylinder 6, and there is a gap between the outer wall of the inner cylinder 7 and the inner wall of the outer cylinder 6; both the outer cylinder 6 and the inner cylinder 7 are made of ceramic Material.

[0037] The upper port of the inner cylinder 7 and the outer cylinder 6 is provided with an upper end cover 12, the lower port of the outer cylinder 6 is provided with a lower end cover 13, and the upper side wall of the outer cylinder 6 is provided with an air inlet pipe 1, and the air inlet pipe 1 A fuel inlet 3 is provided on the side wall; the air inlet pipe 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com