Composite material, thin film and preparation method thereof, quantum dot light-emitting diode

A quantum dot light-emitting and composite material technology, which is applied in the field of quantum dot light-emitting diodes, can solve the problems of many surface defect states and unfavorable charge balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

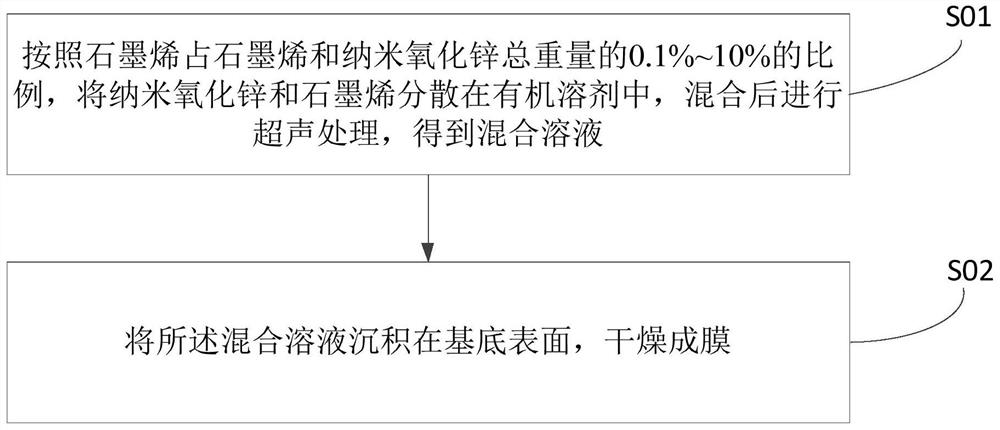

[0033] Correspondingly, refer to figure 2 Shown is a schematic flowchart of a method for preparing a thin film according to an embodiment of the present invention. An embodiment of the present invention provides a method for preparing a thin film, including the following steps:

[0034] S01. according to the ratio that graphene accounts for 0.1%~10% of the total weight of graphene and nano-zinc oxide, nano-zinc oxide and graphene are dispersed in an organic solvent, and ultrasonic treatment is carried out after mixing to obtain a mixed solution;

[0035] S02. Deposit the mixed solution on the surface of the substrate, and dry to form a film.

[0036] In the method for preparing the film provided in the embodiment of the present invention, graphene and nano-zinc oxide are dispersed in an organic solvent according to the dosage ratio, and after mixing, ultrasonically dispersed, the obtained mixed solution is deposited on the surface of the target substrate of the film to be dep...

Embodiment 1

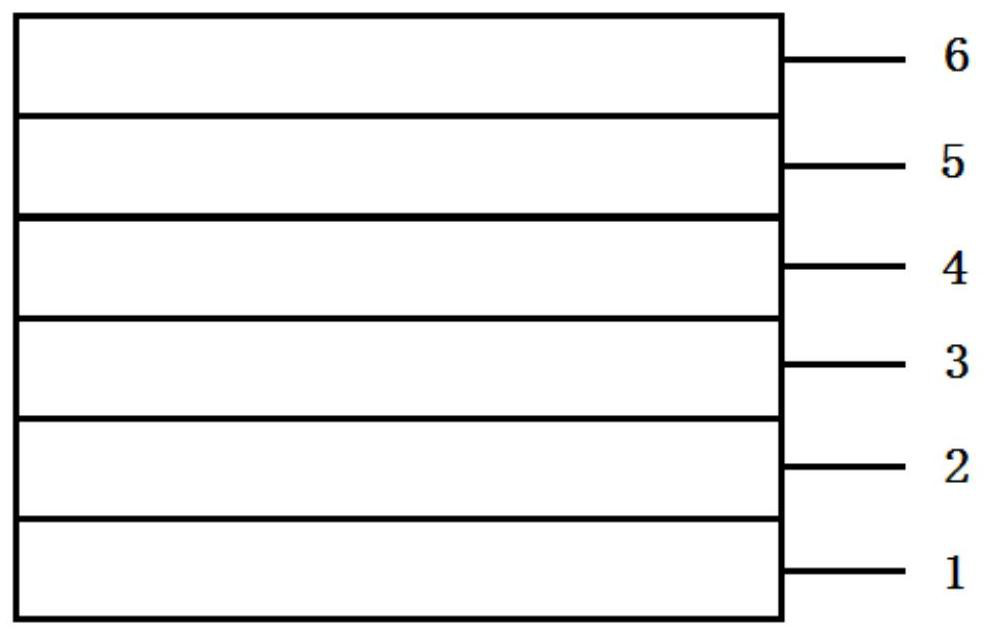

[0072] A quantum dot light-emitting diode, comprising a substrate, an anode and a cathode arranged on the substrate, a stacked structure arranged between the anode and the cathode, the stacked structure comprising a stacked hole injection layer - hole transport layer - quantum dot light emitting layer - electron transport layer, wherein the hole injection layer is arranged adjacent to the anode and the electron transport layer is arranged adjacent to the cathode.

[0073] The preparation method of the quantum dot light-emitting diode comprises the following steps:

[0074] depositing a hole injection layer on the anode substrate, depositing a hole transport layer on the hole injection layer, and depositing a quantum dot light-emitting layer on the hole transport layer;

[0075] The composite material solution of graphene / ZnO is spin-coated on the quantum dot light-emitting layer, and placed in a heatable device, wherein the heatable device comprises a bottom plate and a top pl...

Embodiment 2

[0078] The difference from Example 1 is that the heating temperature of the bottom plate is 60° C., the heating temperature of the top plate is 100° C., and the height between the bottom plate and the top plate is taken as h, the The substrate is placed between h / 3 and 2h / 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com