Multi-level hot-air drying system

A technology of hot air drying and hot air devices, which is applied in the direction of drying machine combination, progressive drying machine, drying solid materials, etc., can solve the problems of high cost, low efficiency, occupying land area, etc., and achieve controllable output, thorough drying, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

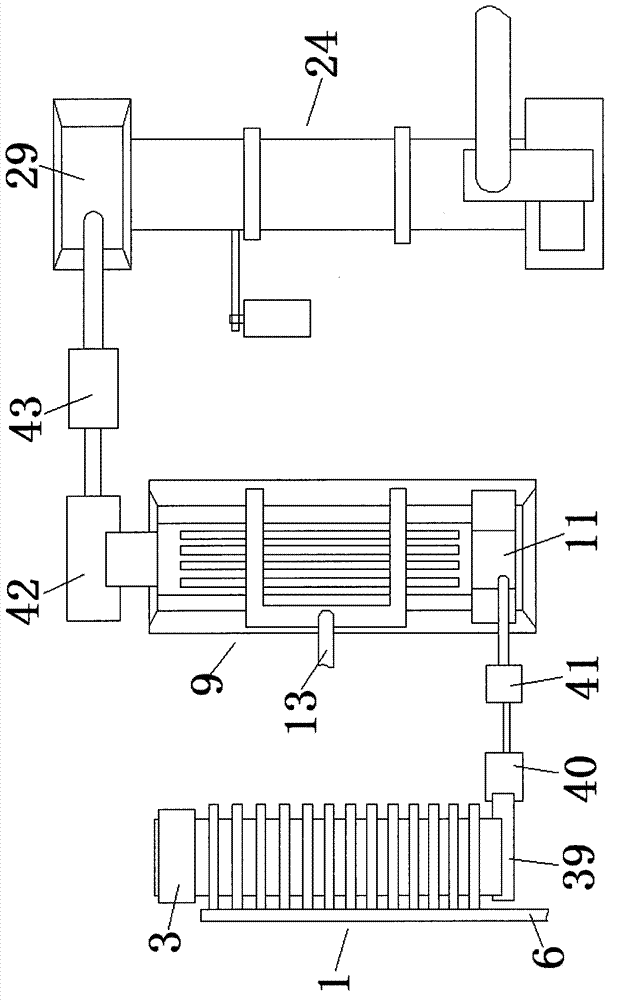

[0032] Such as figure 1 As shown, the multi-stage hot air drying system described in the embodiment of the present invention includes a primary surface drying device 1, a deep surface drying device 9 and a solidification drying device 24, wherein the first two devices are used for surface drying of sand materials. Drying, the third device solidifies and dries the sand material to discharge the moisture inside the sand material.

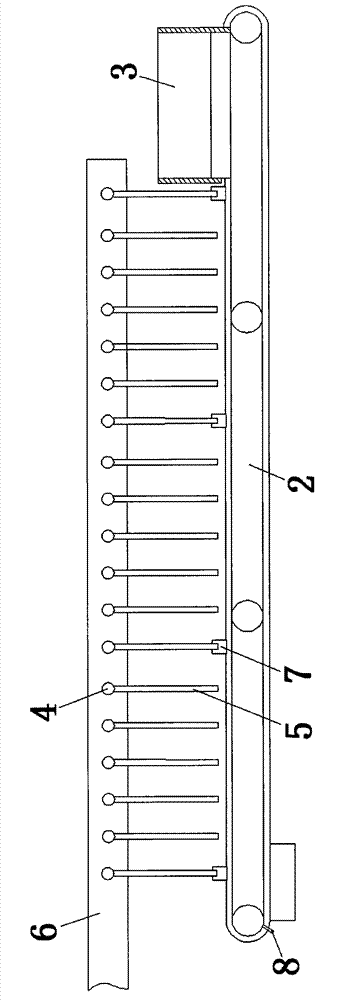

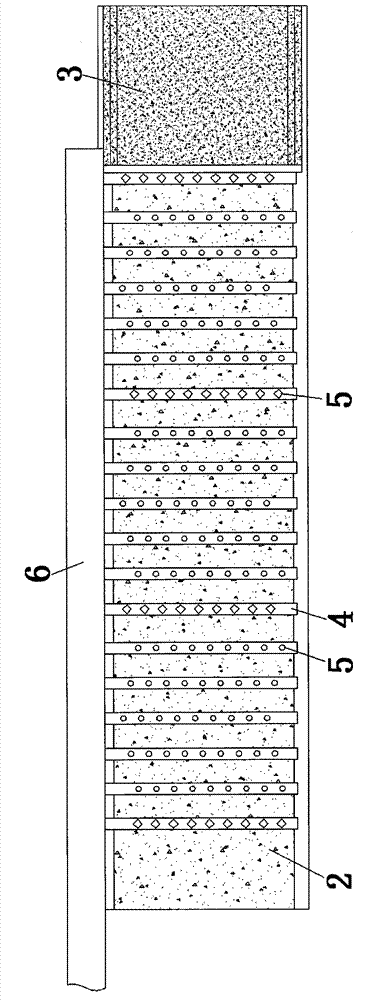

[0033] Such as Figure 2-3 As shown, the primary surface drying device 1 includes a conveying belt 2, the feeding end of the conveying belt 2 is provided with a first hopper 3, and the first hopper 3 has four sides, wherein the sides on both sides Bending inwards, the width of the outlet at the bottom of the first hopper 3 is less than the width of the conveyor belt 2, and the bottom feeding side of the first hopper 3 is provided with a feeding port, and the shape of the feeding port is used to limit The shape and thickness of the sand layer, so the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com