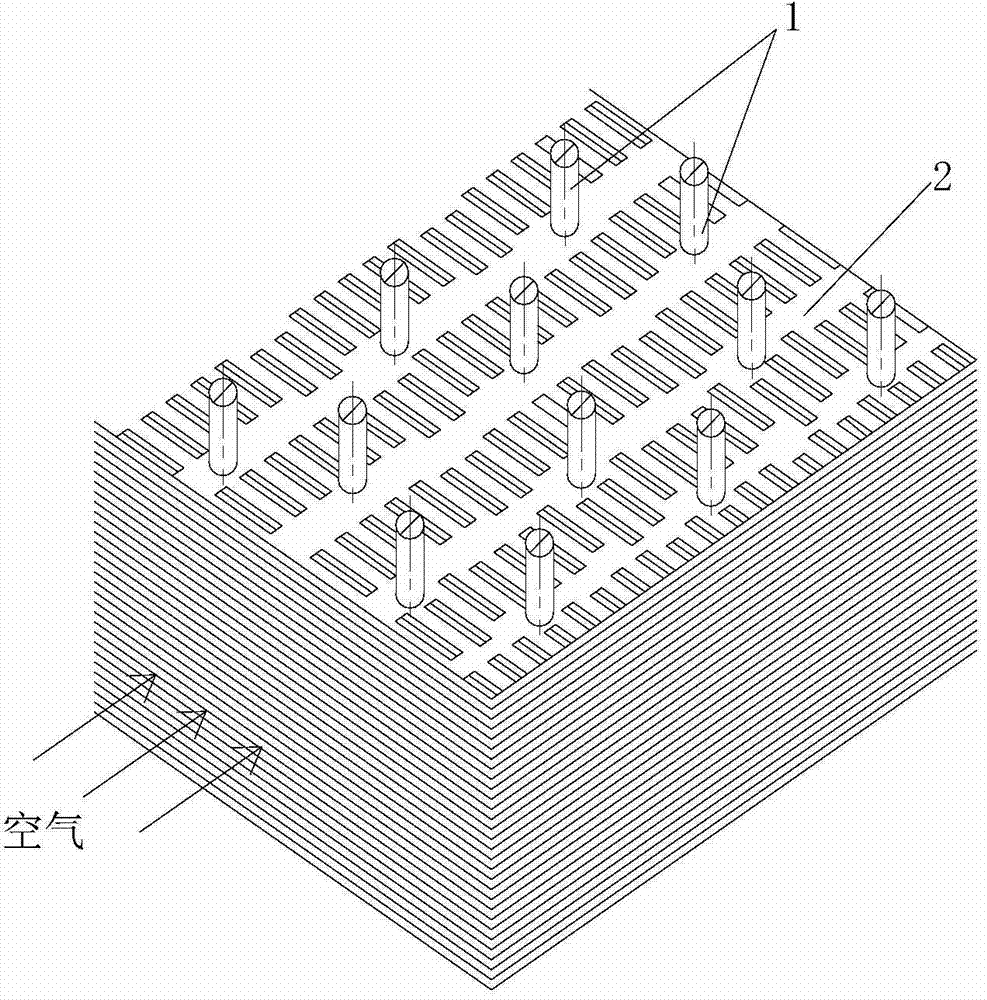

Nonuniform finned radiator for Heller type indirect air cooling system

A technology of finned radiators and air cooling systems, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of reduced cooling efficiency of air cooling towers, unfavorable heat dissipation of radiators, longitudinal vortex of radiators, etc. , to achieve the effects of weakening the vortex, balancing heat transfer, and reducing ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

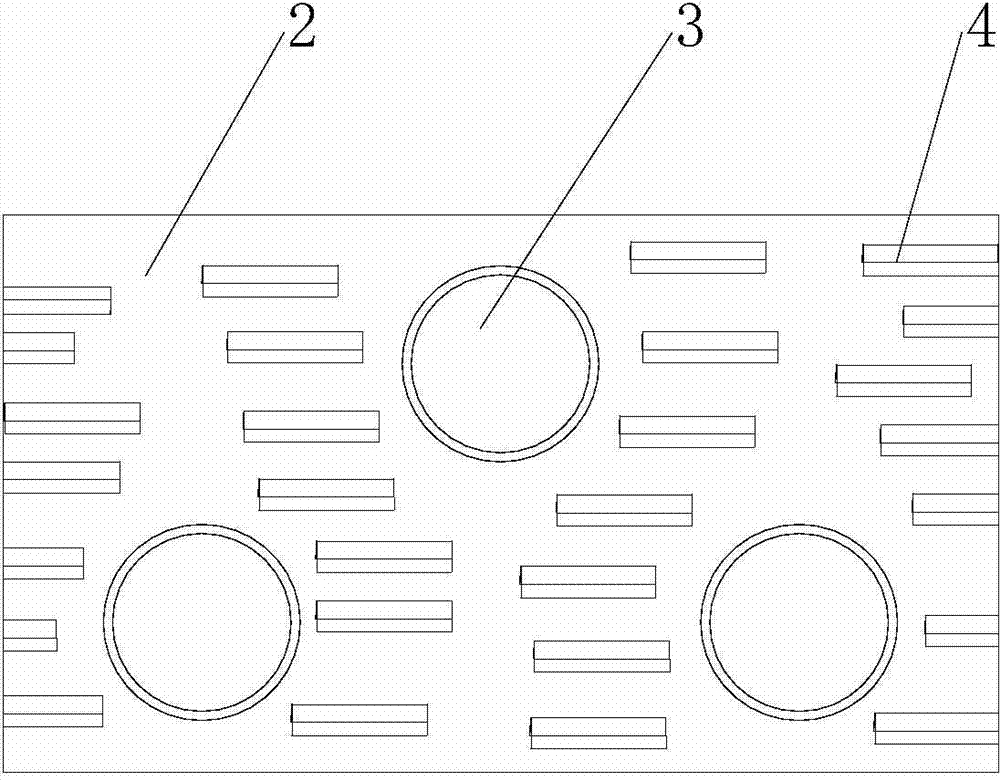

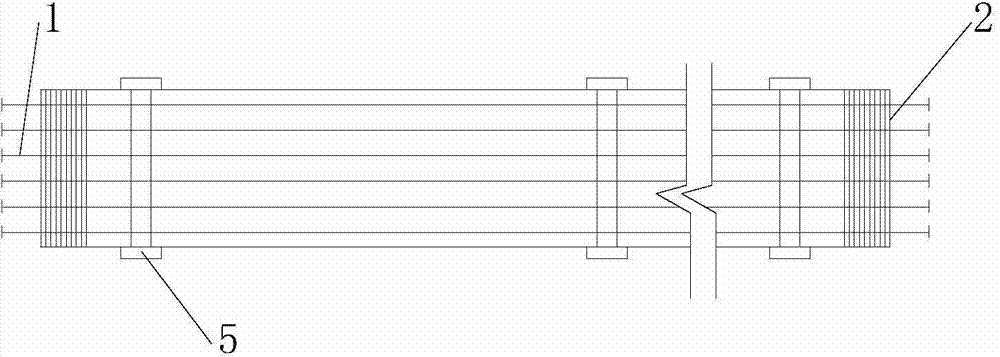

Embodiment 1

[0033] In this embodiment, the radiator is divided into three parts according to the height direction, the top, the middle, and the bottom. The proportions of the three parts to the total height are 5%, 85% and 10% respectively. 1 =2d=5.76mm, the bottom fin spacing is d 3 =1.8d=5.184mm, other parameters of the fins remain unchanged, where d is the fin spacing when the cooling fins are evenly arranged, 2.88mm.

Embodiment 2

[0035] In this embodiment, the radiator is divided into three parts according to the height direction, the top, the middle, and the bottom, and the proportions of the three parts to the total height are 10%, 80% and 10% respectively, and the fin spacing between the top and the bottom is d 1 = d 3 =1.8d=5.184mm, other parameters of the fin remain unchanged.

Embodiment 3

[0037] In this embodiment, the radiator is divided into three parts according to the height direction, the top, the middle, and the bottom, and the proportions of the three parts to the total height are 15%, 70% and 15% respectively, and the fin spacing between the top and the bottom is d 1 = d 3 =1.6d=4.608mm, other parameters of the fin remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com