A four-point measurement method of intersecting parameters and clamping pose of intersecting double pipes based on nonlinear equations

A technology of non-linear equations and measurement methods, applied in the field of automatic welding control, can solve the problems of affecting operation efficiency, cumbersome process, low efficiency, etc., and achieve the effect of improving operation efficiency, high measurement accuracy and fewer measurement points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

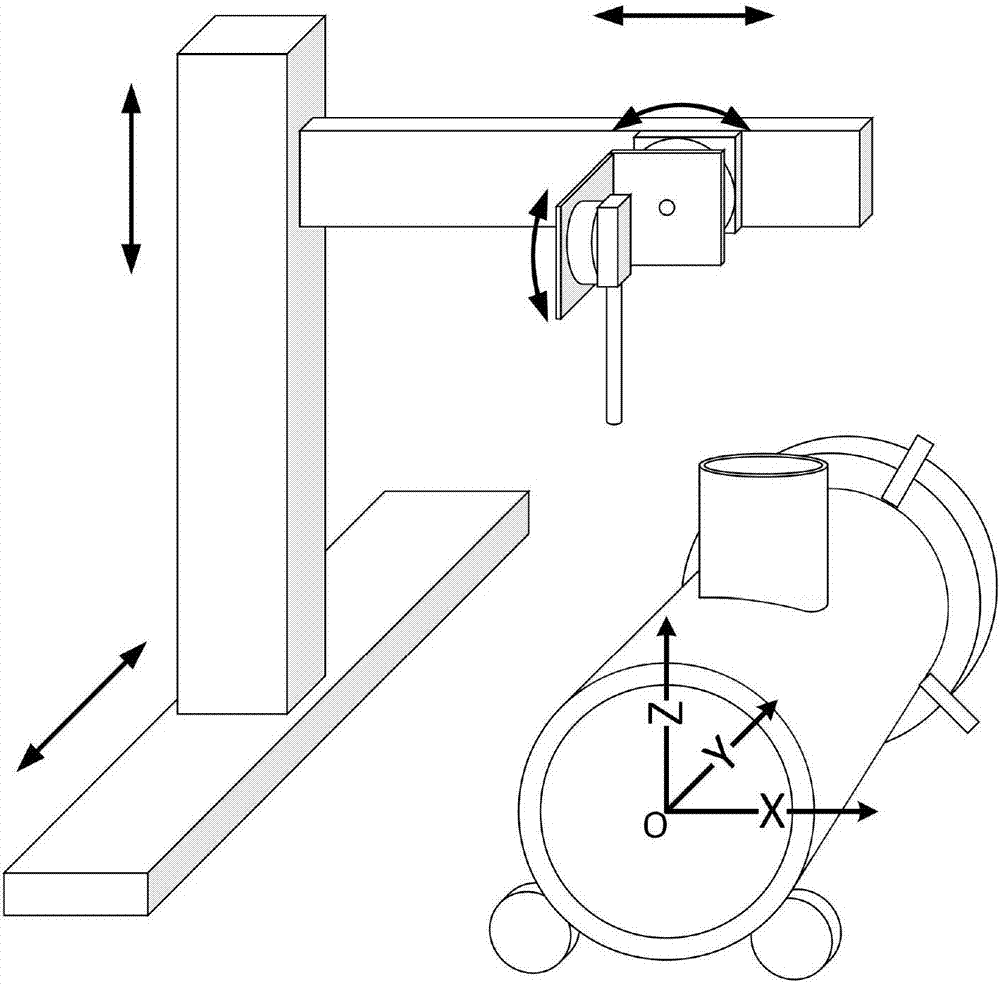

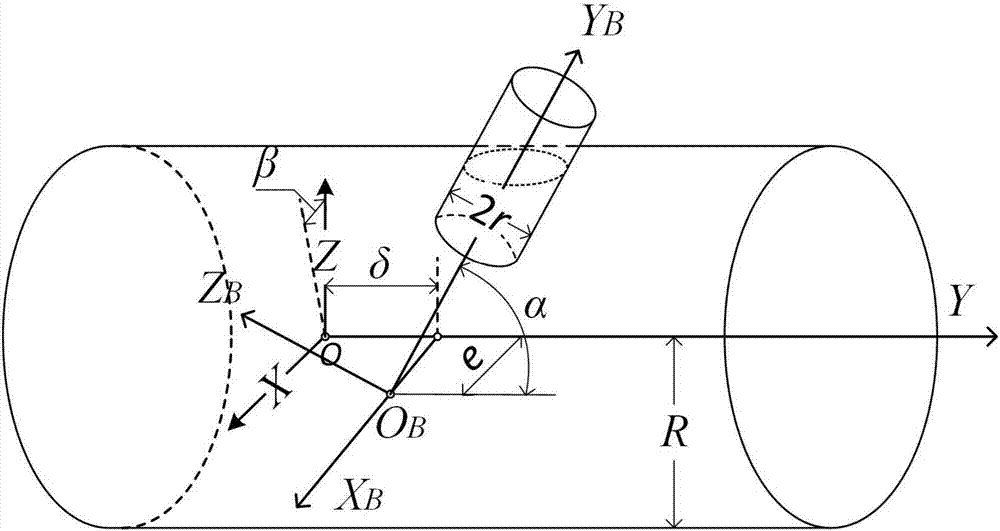

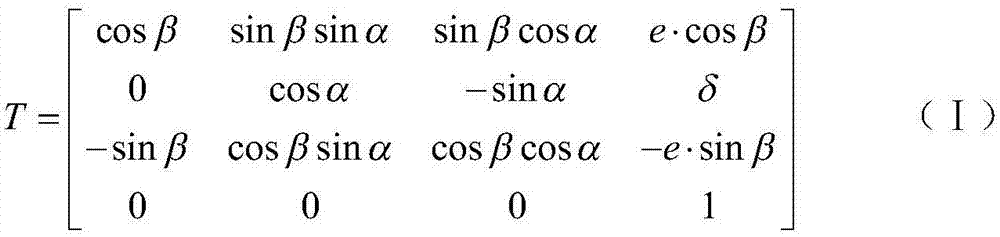

[0035] Such as figure 1 and figure 2 As shown, this embodiment provides a four-point measurement method for intersecting parameters and clamping poses of intersecting double pipes based on nonlinear equations. The method is based on numerical control measurement, mathematical model establishment, and nonlinear equation solving. The machine tool coordinates of four arbitrary points on the outer wall of the branch pipe are measured on the machine tool itself, and combined with the estimated parameters to be solved to solve the initial value, the intersecting parameters and clamping pose parameters of the double pipe can be obtained.

[0036] The structure of the intersecting line welding machine is similar to that of a five-axis milling machine, consisting of three linear axes and two rotary axes. The specific structure is as follows figure 1 As shown, the rotation axis is used to adjust the posture of the welding torch, and the linear axis is used to adjust the position of th...

Embodiment 2

[0060] This embodiment provides a four-point measurement method for intersecting parameters and clamping poses of intersecting double pipes based on nonlinear equations. The method steps are as described in Embodiment 1, and the difference is that: after four When selecting the location of a measuring point, follow a certain distribution rule:

[0061] a. The four measurement points are divided into two groups, each group has two measurement points;

[0062] b. Two groups of measurement points are distributed according to the direction of the central axis of the branch pipe, one group of measurement points is close to the main pipe, and the other group of measurement points is far away from the main pipe;

[0063] c. The angle difference between the two measurement points of each group along the circumferential direction of the branch pipe is 90°±30°.

[0064] The measurement points selected according to this distribution rule can minimize the impact of measurement errors on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com