Interface defect detection method and interface defect detection device of metal-dielectric medium thin-layer bonding or coating structure

A technology of interface defect and detection method, which is applied in measurement devices, material analysis by electromagnetic means, instruments, etc., can solve problems such as difficulty in detection of interface defects, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

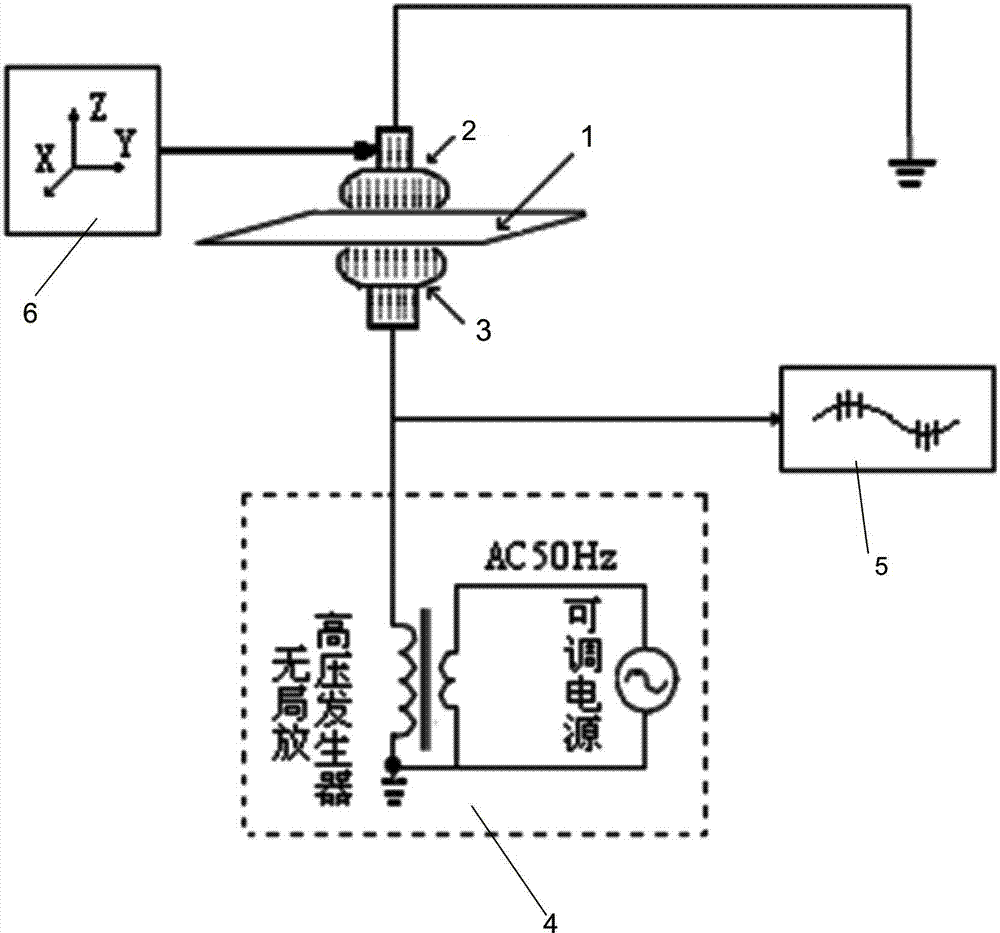

[0025] A method for detecting interface defects of a metal-dielectric thin-layer bonding or coating structure, the method is: applying a certain electric field on both sides of the object to be tested 1, and the partial discharge phenomenon will first appear on the defective part of the object to be tested 1 , by monitoring the discharge signal, it can be judged whether there is a defect in the product under test 1, and the defect location can be performed.

[0026] The method includes the following steps:

[0027] 1) Place the test object 1 on the basic platform formed by the fixed electrodes, and the mobile electrodes can move on the test object 1;

[0028] 2) Apply a certain electric field to both sides of the test product 1 by applying a certain high voltage on both sides of the test product 1;

[0029] 3) Adjust the voltage to change the size of the electric field, so that the discharge signal cannot be detected in most positions of the test object 1;

[0030] 4) Move t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com