Differential evolution algorithm based multi-layer frequency selection surface composite wave-absorbing structure and material optimum design method

A frequency selective surface, differential evolution algorithm technology, applied in the field of absorbing materials, can solve the problems of long design cycle, lack of directional guidance in the design of absorbing materials, large workload, etc., to achieve the effect of shortening the design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

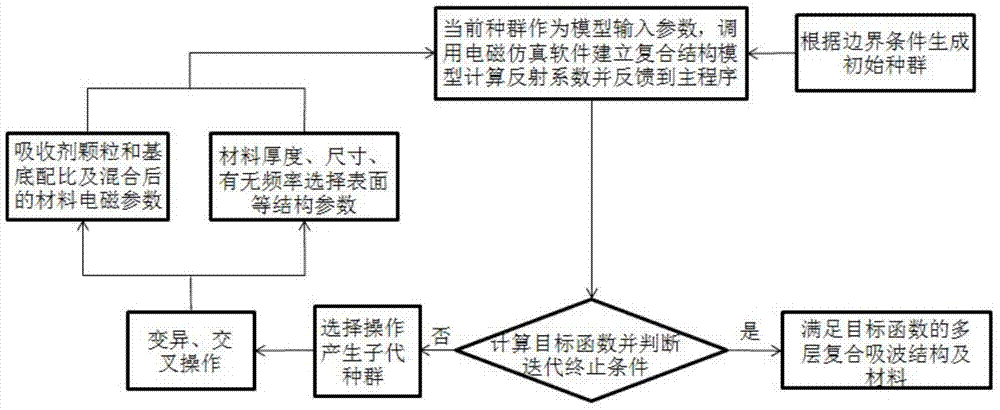

[0040] figure 1 A differential evolution algorithm multi-layer wave-absorbing composite structure and material optimization design method provided for the embodiment of the present invention includes the following steps:

[0041] Step 1: Determine the objective function of the optimized composite absorbing model and the characteristic parameter variables and boundary conditions that affect it, initialize the variable parameters, and the iteration number G=0;

[0042] In said step 1, the objective function of the composite structure model optimization of establishment is:

[0043] T = ω 1 T 1 +ω 2 T 2

[0044] Among them, T represents the objective function value, ω 1 , ω 2 Indicates the weight coefficient, which can be a certain non-negative real number, which is determined according to the importance of the total thickness of the composite mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com