Method and device for automatically monitoring on-the-job state of automatic detonator filling production line personnel

A technology of automatic filling and automatic monitoring, applied in instruments, closed-circuit television systems, alarms, etc., can solve the problems of artificial omission of judgment, untimely supervision of personnel, misjudgment, etc., and achieve the effect of reducing work intensity and reducing unfavorable supervision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

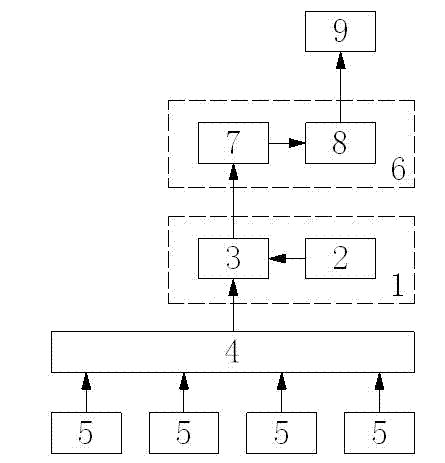

[0015] A method for automatically monitoring the on-duty status of personnel in a detonator automatic filling production line of the present invention is as follows: the method is to install a group of cameras at each station of the production line to monitor the production line in real time without dead ends, and the images captured by the cameras are transmitted to the monitoring room in real time; The monitoring room is equipped with an automatic video signal identification device. The video signal automatic identification device compares the video signal collected on site with the standard video signal captured in the normal production state. When the comparison result exceeds the set range, the video signal is automatically identified. The device sends out an early warning signal to remind the person...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com