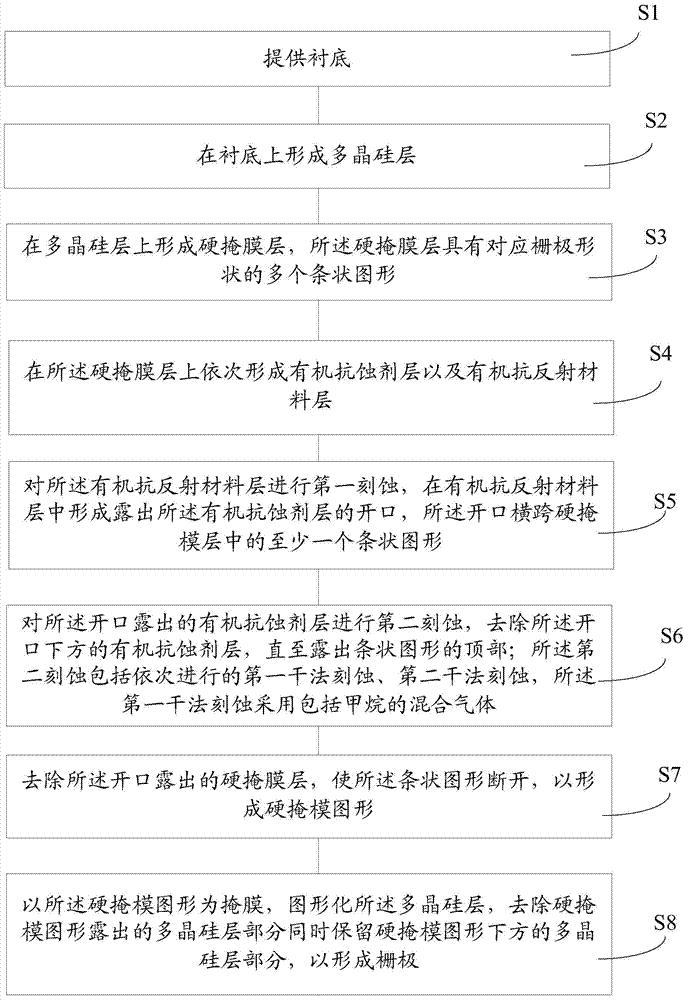

Grid electrode forming method

A gate and pattern technology, applied in semiconductor devices and other directions, can solve problems such as increasing design value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

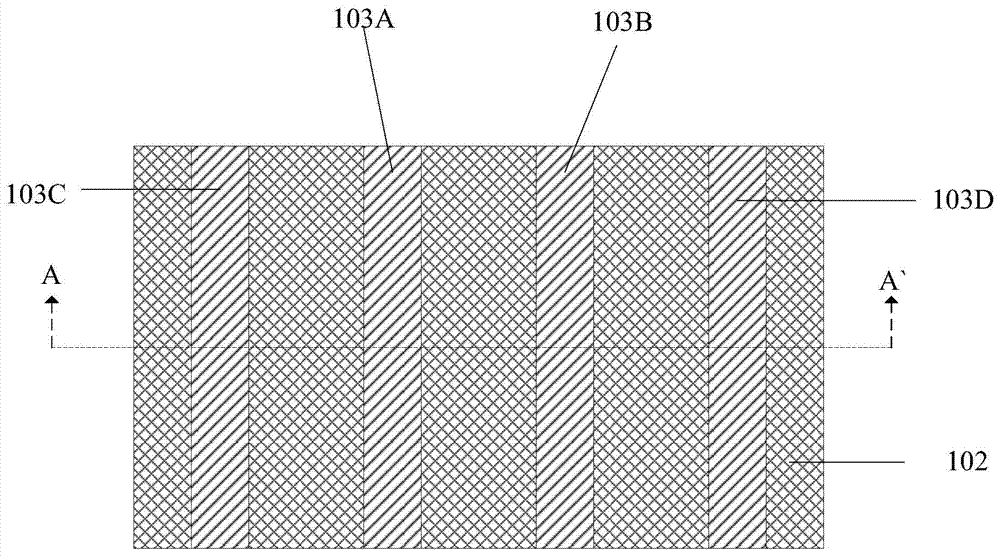

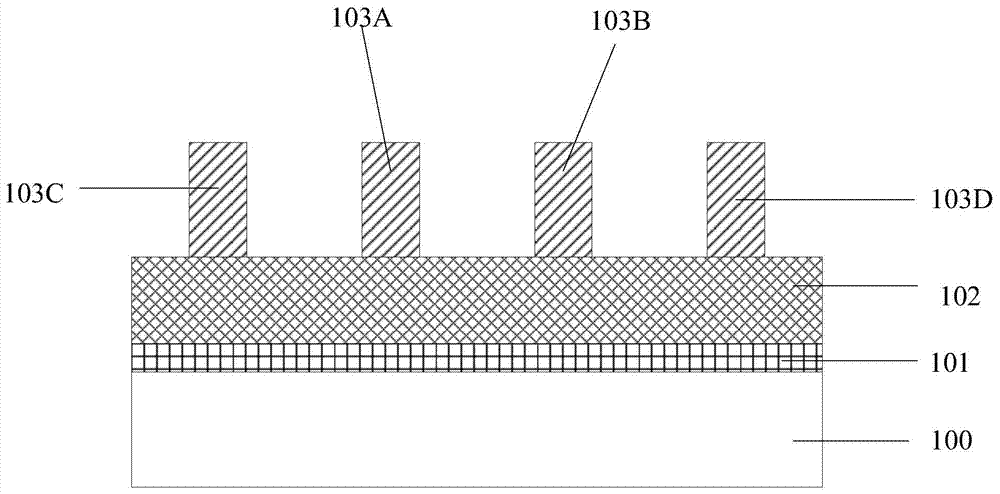

[0029] In the design of narrowing the connecting direction of the gates, the strip-shaped gates are cut by two photolithography steps, but the spacing in the connecting direction of the finally formed and disconnected strip-shaped gates is larger than the designed value.

[0030] In order to obtain the reason why the pitch of the butt joint direction of the strip-shaped gates is larger than the design value, the process of gate cutting in the prior art is analyzed. In the prior art, the dielectric layer usually includes a top-down organic anti-reflective material layer and an organic resist layer. When etching the dielectric layer to form openings, chlorine gas or hydrogen bromide is usually used to etch the organic resist layer. , so that the opening exposes the top of the stripe pattern in the hard mask layer, but the anisotropy of etching with chlorine or hydrogen bromide is poor, and if the etch intensity is low, the organic resist located above the stripe pattern Residue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com