Organic image sensor and forming method thereof

An image sensor, an organic technology, applied in the field of image sensors, can solve the problems of limiting the absorption of incident light, organic image sensors need to be further improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

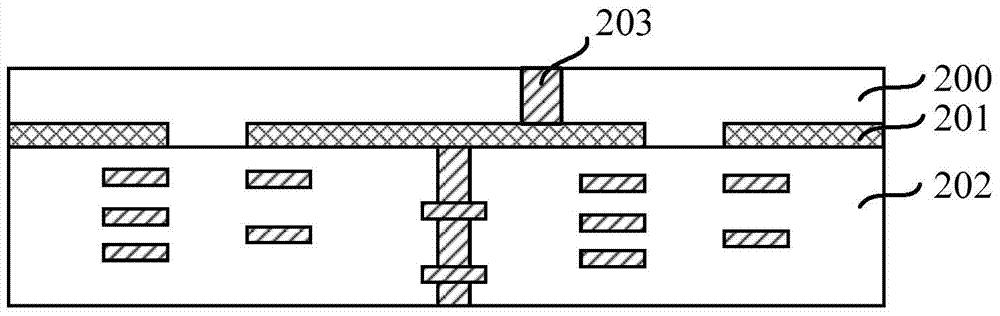

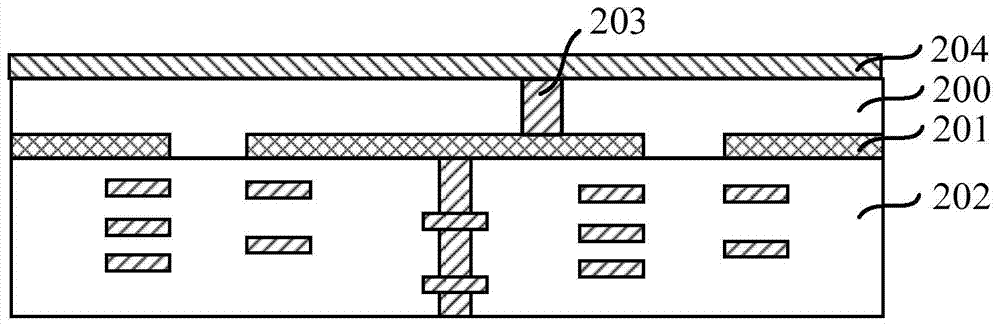

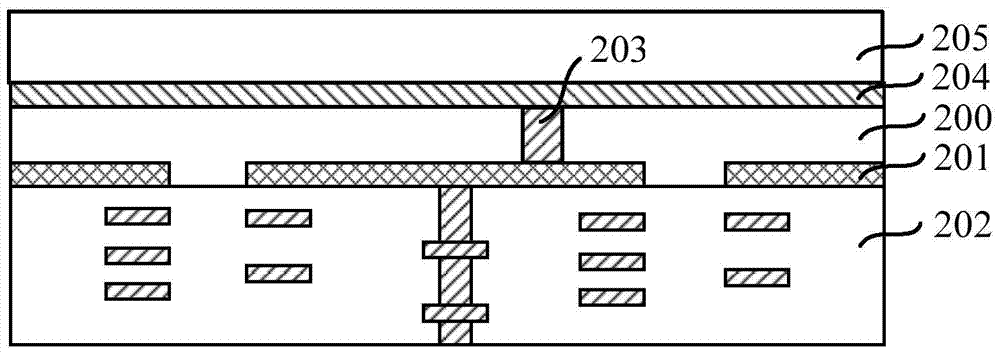

[0035] After research, the structure of the existing organic image sensor includes: a substrate, several discrete pixel lower electrodes located on the substrate; an organic photoelectric conversion layer located on the pixel lower electrode; and an upper electrode located on the organic photoelectric conversion layer. When external light is incident from above the upper electrode, the organic photoelectric conversion layer induces the light to generate charges, and receives the induced charges through the upper electrode and the corresponding lower electrode of the pixel. However, since the existing organic photoelectric conversion layer has a whole-layer structure, interference between adjacent pixel units is likely to occur when sensing light, and when external light is incident at a certain oblique angle, the incident light above a certain pixel unit The light will also irradiate into the organic photoelectric conversion layer corresponding to the adjacent pixel unit, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com