Damaged cable repairing pouring device and pouring usage method

A cable and repair technology, applied in the direction of insulation/armored cable repair equipment, etc., can solve the problems of easy aging of cables, damaged protective layer, damage, etc., to avoid leakage and short circuit, improve repair efficiency, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

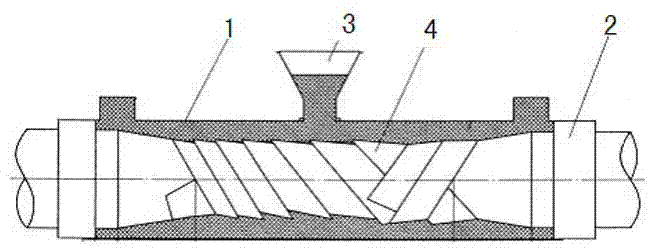

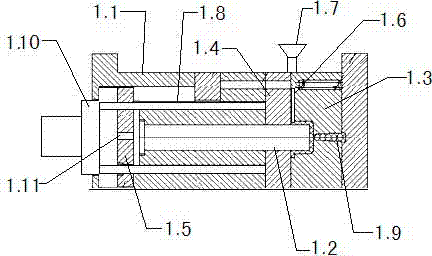

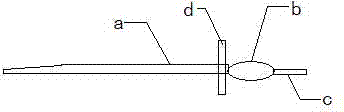

[0026] combined with Figure 1-3 , to further describe the present invention:

[0027] The invention comprises a reel mold 1, a sealing block 2, and a mixing chamber 3, the two ends of the reel mold 1 are provided with a sealing block 2, and the top of the reel mold 1 is provided with a mixing chamber 3, and the characteristics are: the reel Mold 1 comprises mold body 1.1, and described mold body 1.1 comprises upper mold body and lower mold body, and the middle of described upper mold body and lower mold body is provided with mold cavity 1.2, and one end of mold cavity 1.2 is provided with fixed plate 1.3, The other end of the mold cavity 1.2 is provided with a push-pull rod fixing block 1.5, and the middle of the mold cavity 1.2 is provided with a slider 1.4. The slider 1.4 is connected with a push-pull rod 1.8, and the push-pull rod passes through the push-pull rod fixing block 1.5 to connect to the stretching head 1.10, there is a pouring slot 1.6 between the slider 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com