Method for manufacturing shell of motor

A technology for motors and casings, which is applied in the field of manufacturing motor casings for motors, and can solve problems such as high cost and poor sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The advantage of a tubular base shell is that it can be designed as a stretched or extruded tube, which can be produced cost-effectively.

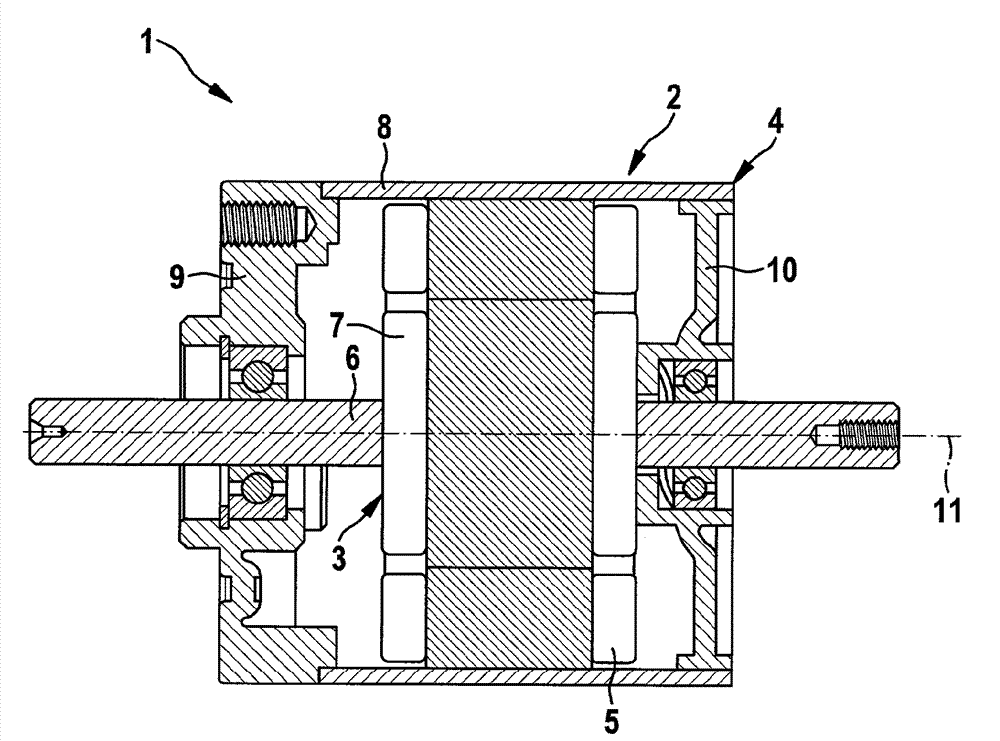

[0023] exist figure 1 An electric motor 1 is shown in longitudinal section, which is designed as an internal mover motor and comprises a stator 2 and an inner rotor 3 . Both belong to the stator 2 , as well as the stator part 5 arranged on the inner side of the motor housing 4 and which excites the magnetic field, which is designed either as a permanent magnet or as an energizable coil. A motor shaft 6 , which is rotatably mounted in the motor housing 4 , and an armature assembly 7 placed on the motor shaft 6 , which has coils which are energized via a rectifier, belong to the rotor 3 .

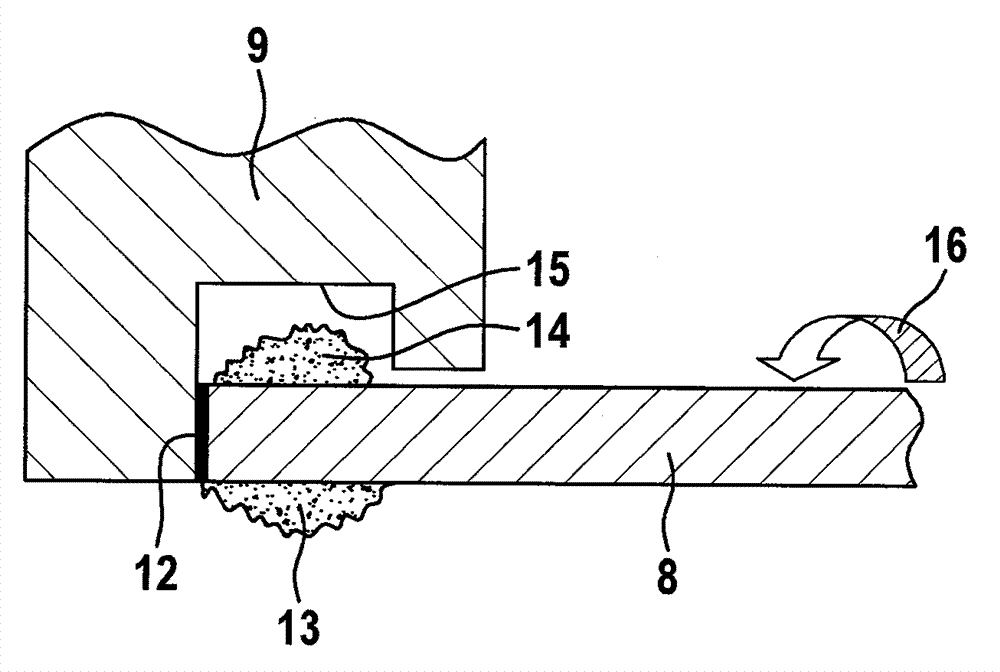

[0024] The motor housing 4 is constructed in multiple parts and comprises a cylindrical, tubular base housing 8 and two covers 9 and 10 arranged on the end faces of the base housing 8 . The covers 9 and 10 are joined to the base shell 8 in a fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com