Mould material mixtures on the basis of inorganic binders, and method for producing moulds and cores for metal casting

A technology of inorganic binders and mold materials, which is applied in the direction of manufacturing tools, casting molding equipment, cores, etc., and can solve the problems of inorganic binders losing meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0104] 1. Heat curing

[0105] 1.1. Experiment 1: With the addition of particulate amorphous SiO 2 The strength and core weight vary with the type of

[0106] 1.1.1 Preparation of mold mixture

[0107] 1.1.1.1 Addition of SiO 2

[0108] The quartz sand was placed in the bowl of a Hobart mixer (model HSM 10). While stirring, the binder was subsequently added, the binder mixed intensively with the sand for 1 minute in each case. The types of sand, binders used and the amounts of each added are shown in Table 1.

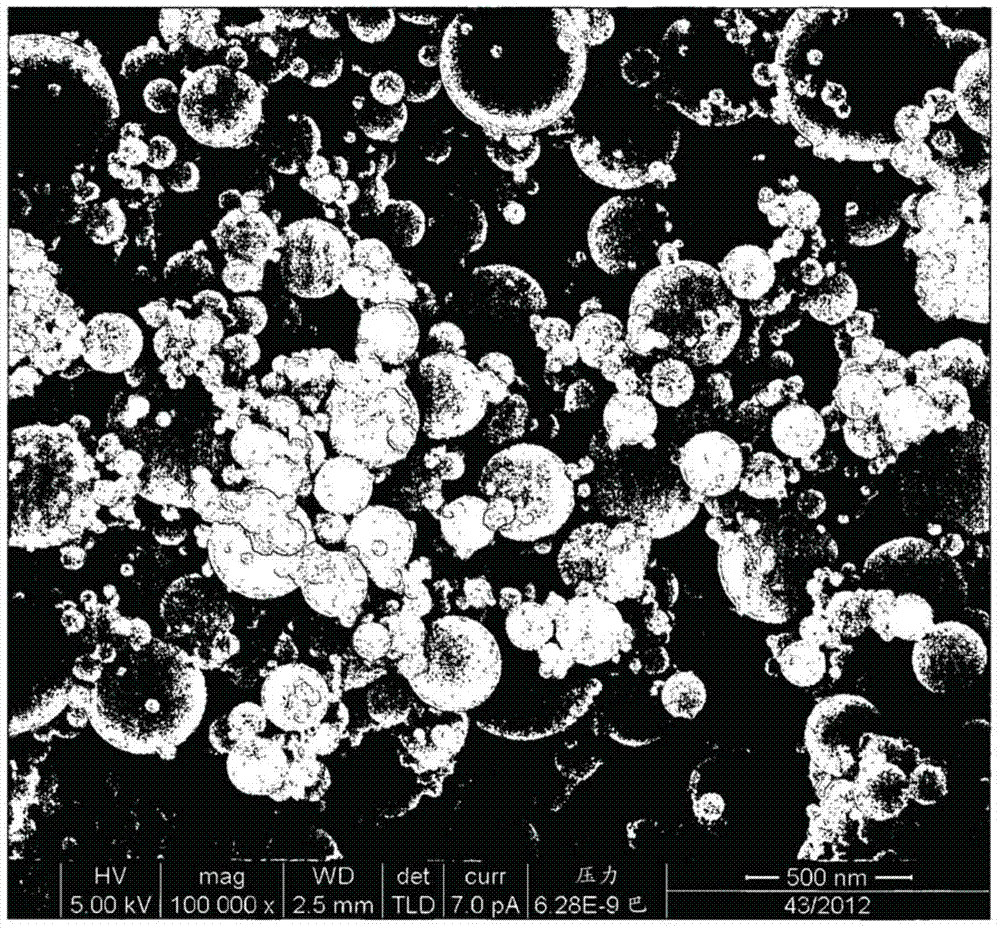

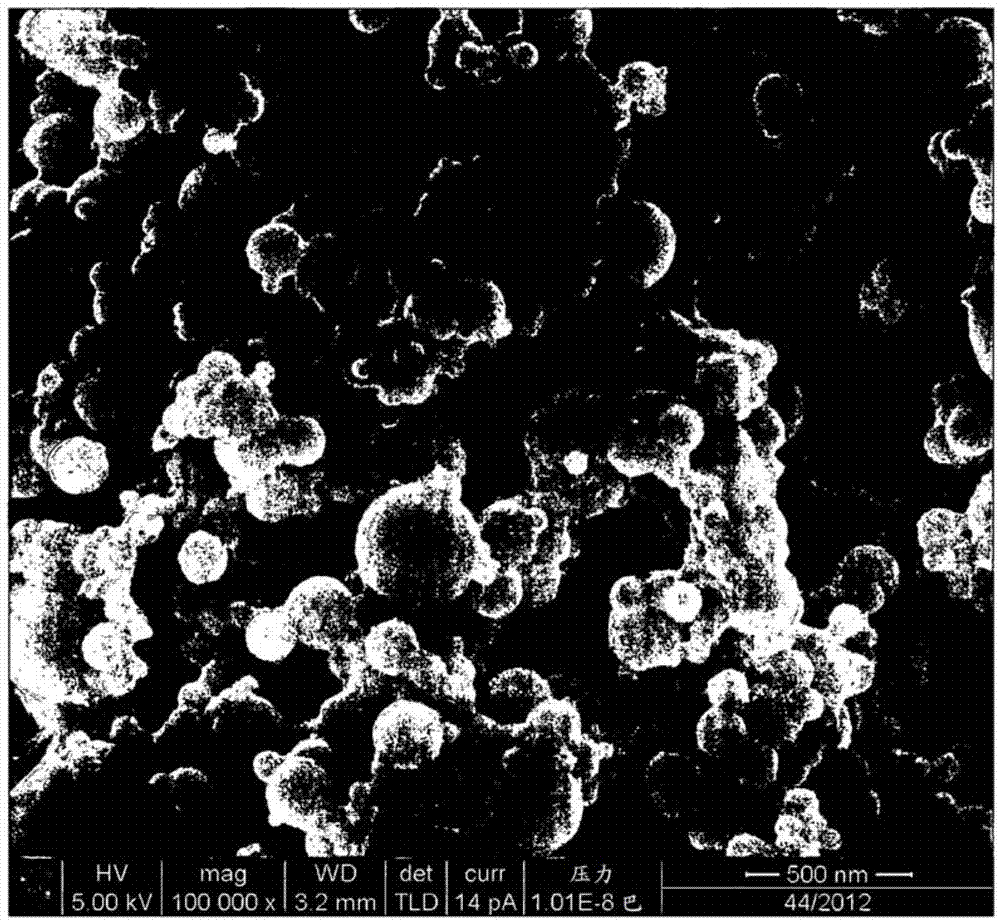

[0109] 1.1.1.2 Add SiO 2

[0110] Follow the procedure of 1.1.1.1, except that after the binder is added to the mold material mixture, the particulate amorphous SiO 2 , and mix this also for 1 minute. Granular Amorphous SiO 2 The type and amount added are shown in Table 1.

[0111] Table 1 (Experiment 1) Composition of mold material mixture

[0112]

[0113]

[0114] a) alkali metal water glass; molar modulus about 2.1; solids content about 35% by we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com