Efficient Spiral Screening Machine

A technology of spiral sieve and screening machine, which is applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., and can solve the problems of large and medium-sized agricultural implements not being able to keep up, machinery varieties, specifications, aging of implements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

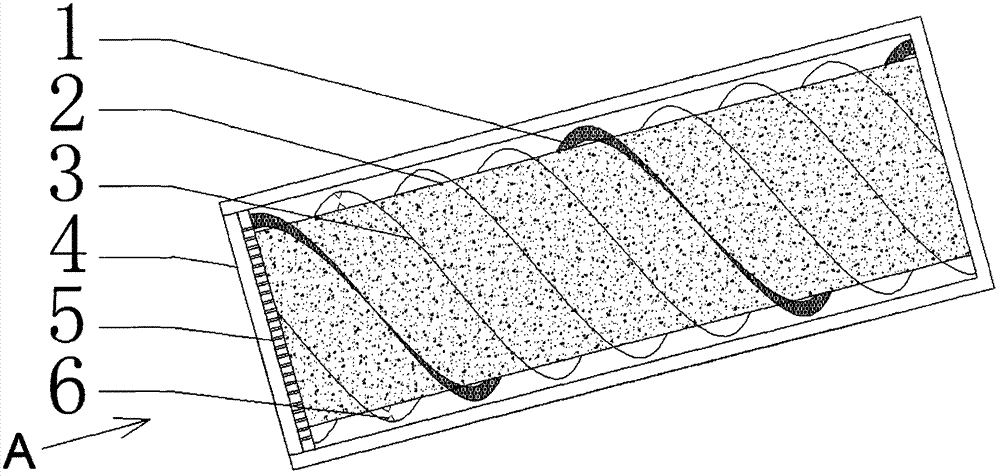

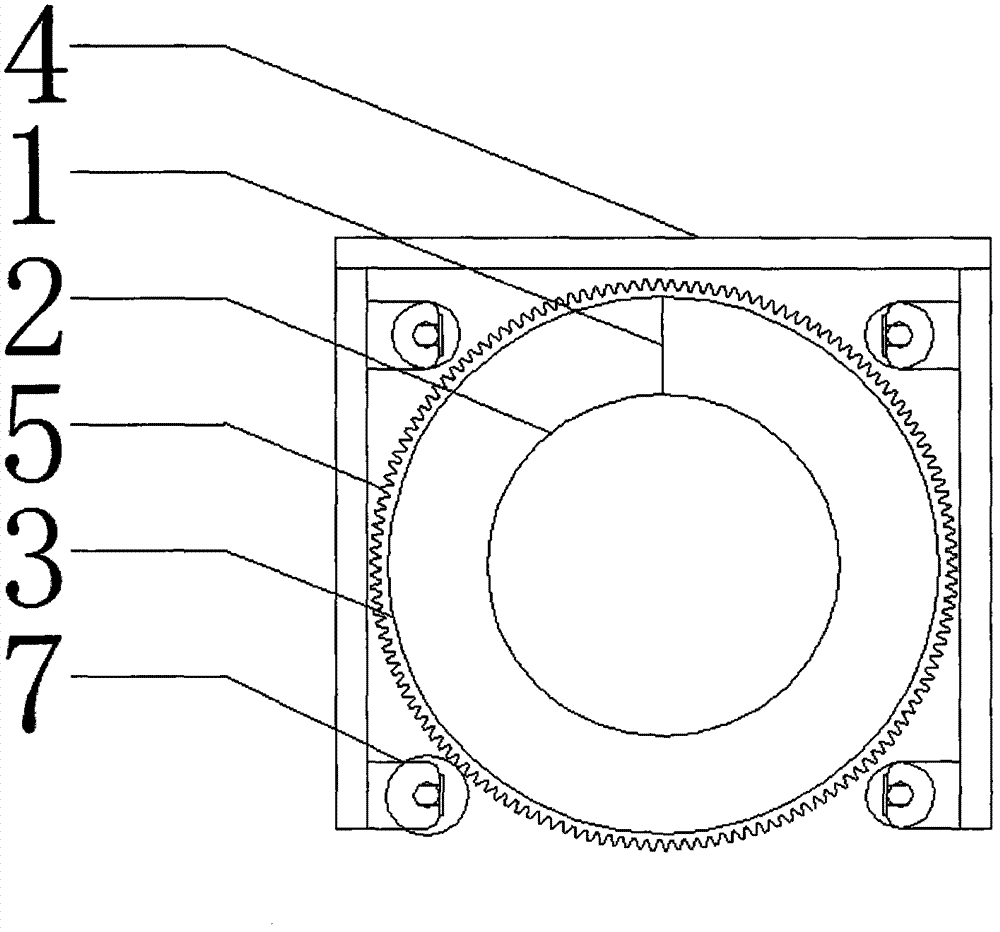

[0021] A high-efficiency spiral screening machine invented and designed is a new mechanical technology integrating lifting, screening, crushing, separation and transportation. according to figure 2 As shown, the position of each device in the high-efficiency spiral screening machine is in order from outside to inside: frame→supporting wheel→gear→outer spiral screen→screw guide plate→triangular crusher→built-in feeder.

[0022] according to figure 1 with figure 2 The function of the label name is introduced as follows:

[0023] The spiral material guide plate is a long strip material. The spiral material guide plate is between the built-in feeder and the outer spiral screen, and is wound along the outer side of the built-in feeder and the inner side of the outer spiral screen with a certain distance. become. The spiral material guide plate is connected with the inner side of the outer spiral screen, and not connected with the built-in feeder, and the width of the spiral m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com