Bone fracture plate for fixing in all directions

A bone plate, omni-directional technology, applied in the direction of fixator, outer plate, internal bone synthesis, etc., can solve the problems of cumbersome nailing operation and removal operation, low thread locking strength, inability to apply bone plate, etc. And the effect of easy and convenient nail removal, improved thread locking strength, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

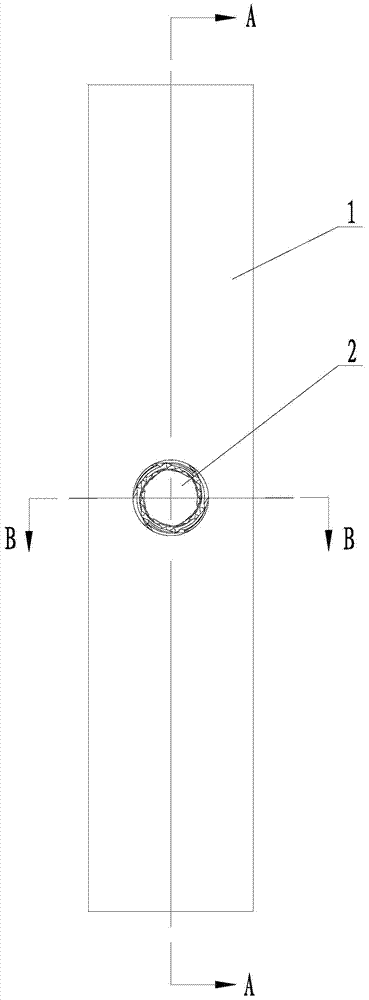

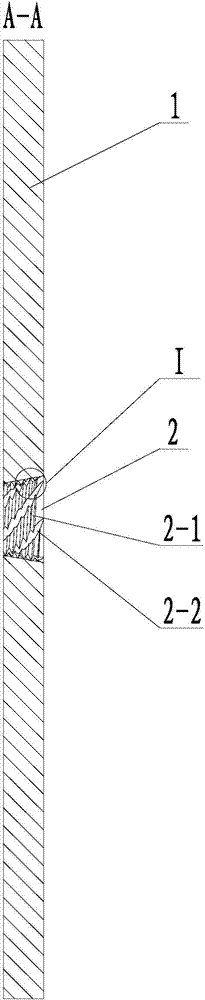

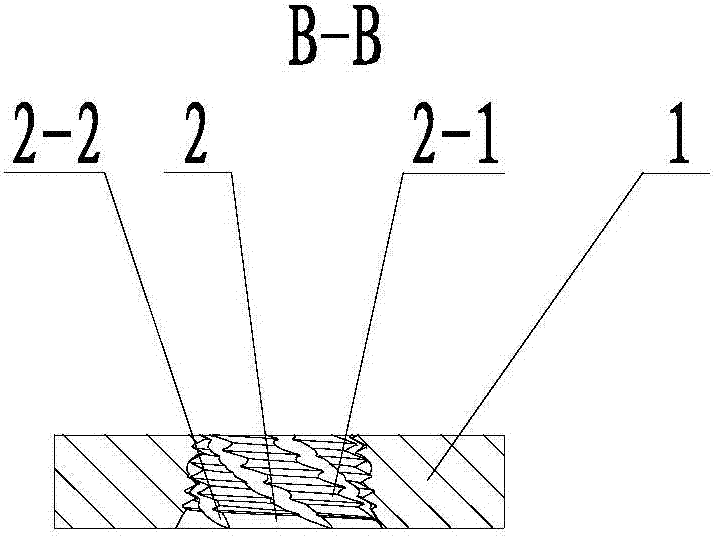

[0034] See figure 1 , figure 2 and image 3 , the omnidirectional fixed bone plate of the present invention comprises a locking plate main body 1 made of steel and a universal locking hole 2 provided on the locking plate main body 1, the universal locking hole 2 is a spherical hole, and the universal locking hole 2 The cone angle is 20°, and the hole wall sphericity of the universal locking hole 2 is 3°.

[0035] See figure 2 and image 3 , the hole wall of the universal locking hole 2 is processed with superimposed helical threads 2-1 and intermittent helical grooves 2-2. The nominal diameter of -1 is 5.0mm, the pitch is 0.4mm, and the lead is 0.8mm; the pitch of intermittent spiral groove 2-2 is 2.0mm, and the lead is 12.0mm.

[0036] See figure 2 , image 3 and Figure 4 , the thread profile of the helical thread 2-1 and the helix angle of the intermittent helical groove 2-2 are both triangular.

[0037] See Figure 4 , the thread tooth angle of the helical thr...

Embodiment 2

[0045] The omnidirectional fixed bone plate of the present invention comprises a locking plate main body 1 made of steel and a universal locking hole 2 opened on the locking plate main body 1, and the universal locking hole 2 is a cylindrical hole. The hole wall of the universal locking hole 2 is processed with superimposed spiral threads 2-1 and intermittent spiral grooves 2-2, the helical threads 2-1 and intermittent spiral grooves 2-2 have the same direction of rotation, and the spiral threads 2- The nominal diameter of 1 is 4.9mm, the pitch is 0.3mm, and the lead is 0.6mm; the pitch of intermittent spiral groove 2-2 is 1.5mm, and the lead is 9.0mm. The thread profile of the helical thread 2-1 and the helix angle of the intermittent helical groove 2-2 are both triangular. Both the thread tooth angle of the helical thread 2-1 and the helix angle of the intermittent helical groove 2-2 are 53°.

[0046]The omnidirectional fixed bone plate is used together with the universal l...

Embodiment 3

[0048] The omnidirectional fixed bone plate of the present invention includes a locking plate main body 1 made of steel and a universal locking hole 2 provided on the locking plate main body 1, the universal locking hole 2 is a conical hole, and the universal locking hole 2 is conical. The angle is 22°. The hole wall of the universal locking hole 2 is processed with superimposed spiral threads 2-1 and intermittent spiral grooves 2-2, the helical threads 2-1 and intermittent spiral grooves 2-2 have the same direction of rotation, and the spiral threads 2- The nominal diameter of 1 is 5.1mm, the pitch is 0.5mm, and the lead is 1.0mm; the pitch of intermittent spiral groove 2-2 is 2.5mm, and the lead is 15.0mm. The thread profile of the helical thread 2-1 and the helix angle of the intermittent helical groove 2-2 are both triangular. Both the thread tooth angle of the helical thread 2-1 and the helix angle of the intermittent helical groove 2-2 are 57°.

[0049] The omnidirecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com