High efficiency fire extinguishing novel technology and device

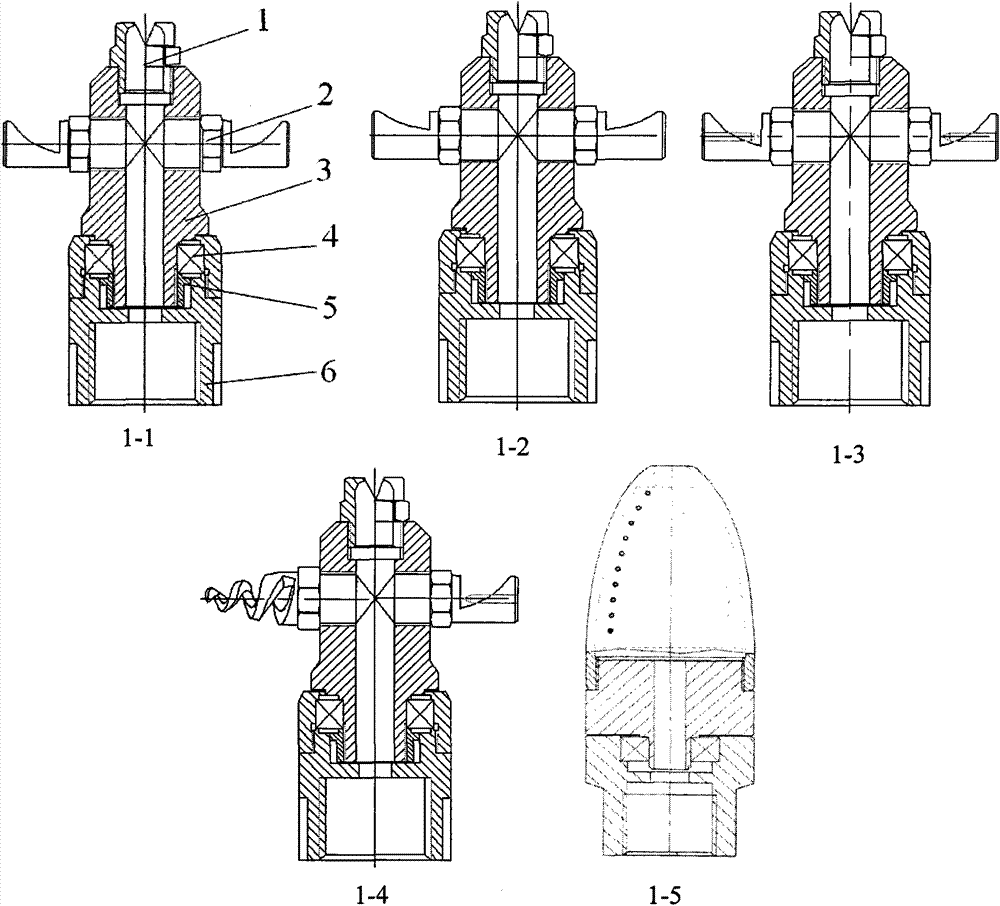

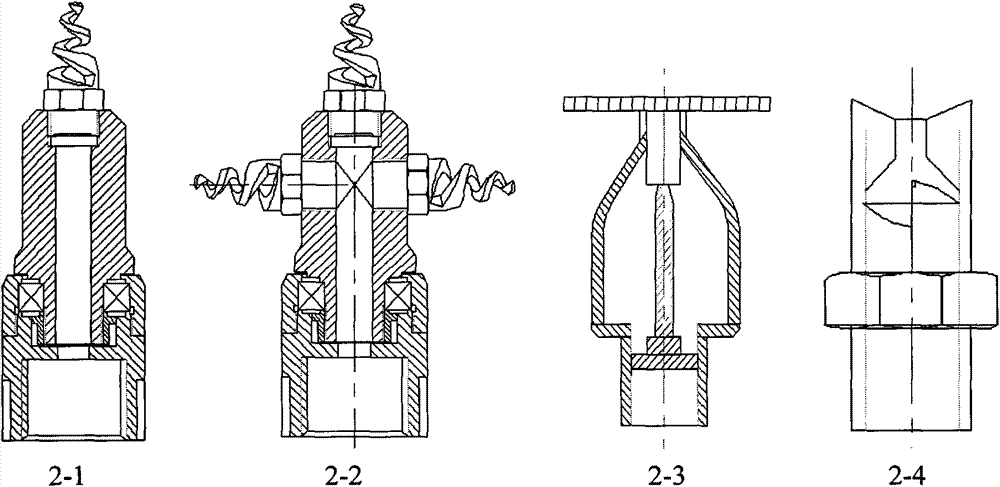

A new technology, applied in the field of rotating water mist rapid fire extinguishing device, can solve the problems of inability to fully utilize the fine water mist to efficiently suffocate fire extinguishing, uneven distribution of spray density, large diameter of mist droplets, etc., to ensure a wide range of uniform coverage, Expand the effective atomization area and promote the effect of full atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

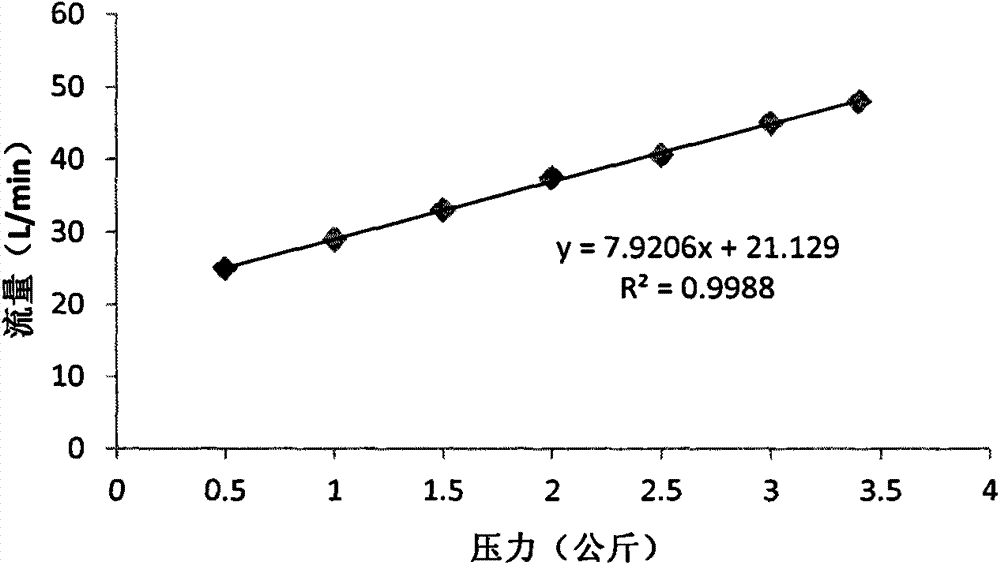

[0035] Embodiment 1: Measurement of pressure and flow rate of three-hole jet rotary nozzle

[0036] Install a three-hole jet rotary nozzle on a test device with a flow meter, use pressurized tap water as the fluid in the test, and adjust the nozzle water pressure to 0.5, 1.5, 2.0, 2.5, 3.0, 3.5 kg respectively. Use a special water tank and a weighing device to collect and weigh the water, and the spraying time is 2 minutes each time. The results are attached figure 2 shown. The experimental results show that: the flow rate of the nozzle has a good linear relationship with the pressure, which can be adjusted according to the needs.

Embodiment 2

[0037] Embodiment 2: the rotating speed of different nozzles under 3 kilograms of pressure

[0038] Install different rotating nozzles on the test device respectively, use clean water for the test, and measure the rotation speed of different nozzles under 3 kg of water pressure, as shown in Table 1. The experimental results show that under the pressure of 3 kg, the rotation speed of various types of nozzles is greater than 10000r / min, among which the rotation speed of the spiral atomization rotary nozzle is the lowest at 10000r / min, and the rotation speed of the three-hole jet rotary nozzle is the highest at 57000r / min min. In terms of speed stability, the stability of the three-hole jet and two-needle atomizing nozzle is the best.

[0039] Table 1 Rotation speed of different nozzles under 3 kg pressure

[0040]

Embodiment 3

[0041] Embodiment 3: the rotating speed of different nozzles feeding air in the air medium

[0042] Air was introduced from the nozzle, and the rotational speeds of different nozzles under different pressures were tested in the air medium, as shown in Table 2. Under the pressure of 0.5 kg, the maximum speed of the three-hole jet and two-needle atomizing nozzle is 11132r / min. Similar to the rotation speeds of different nozzles when water is fed, under the same pressure, the rotation speed of the single-helix mixing rotary nozzle is relatively low, and the rotation speed of the three-hole jet rotary nozzle is relatively high.

[0043] Table 2 Rotational speeds of different nozzles feeding air in air medium

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com